Introducing our range of custom high-quality sheet metal brackets, designed to meet your specific needs with precision and durability. Our light shelf bracket metal stamping parts are crafted to excel in various applications, offering robust support and aesthetic appeal. Whether you require brackets for shelving units, furniture, or industrial equipment, our stamped metal parts deliver exceptional performance and reliability. With a commitment to craftsmanship and attention to detail, we ensure that each bracket meets the highest standards of quality and accuracy. Trust in our expertise to provide you with tailor-made solutions that elevate your projects to new heights.

| Material: | |

|---|---|

| Size: | |

| Availability: | |

| Quantity: | |

OEM/ODM

Our custom sheet metal brackets and precision stamping sheet metal bracket for industrial use are high-strength structural components designed for ToB clients in furniture manufacturing, industrial equipment production, and commercial shelving industries. As a leading sheet metal stamping manufacturer with 16 years of experience, we craft SPCC steel sheet metal shelf brackets and aluminum light shelf parts with exceptional precision and durability, delivering robust support and seamless integration for various installation scenarios. Our stamping parts feature uniform thickness, smooth edges, and customizable hole spacing, making them the ideal solution for OEM/ODM projects requiring reliable structural brackets. Whether for heavy-duty industrial equipment, commercial light shelves, or custom furniture, our custom aluminum light shelf stamping parts balance cost-efficiency and performance, meeting the strict quality standards of bulk production and custom design projects alike.

High-Precision Stamping Technology: Our stamping process achieves ±0.0002in tolerance, ensuring consistent dimensions for mass-produced brackets and perfect fit for custom designs. Cost-Effective Mass Production: With advanced automated stamping lines, we reduce unit costs for bulk orders while maintaining high quality, ideal for large-scale manufacturing clients. Versatile Material Compatibility: We support stamping for aluminum, SPCC, steel, and stainless steel, with tailored processing for different material properties (e.g., lightweight aluminum for shelves, high-strength steel for industrial brackets). 7×24H Drawing & Quotation Service: Our engineering team reviews your custom bracket drawings within 2 hours, providing professional manufacturability suggestions and detailed cost quotes. One-Stop Procurement Solution: From stamping and bending to surface treatment and packaging, we offer end-to-end services to streamline your supply chain and reduce procurement costs.

Specification | Details |

Core Material | Aluminum, SPCC, Steel, 304/316L stainless steel (customizable) |

Size & Design | Fully customized based on customer’s 2D/3D drawings (bracket length, thickness, hole spacing) |

Model Type | OEM/ODM |

Minimum Order Quantity (MOQ) | 1 piece |

Machining Tolerance | ±0.0002in |

Stamping Technology | Precision cold stamping (for thin sheet) / hot stamping (for heavy-duty steel) |

Certification | ISO9001, material certification, QC inspection report |

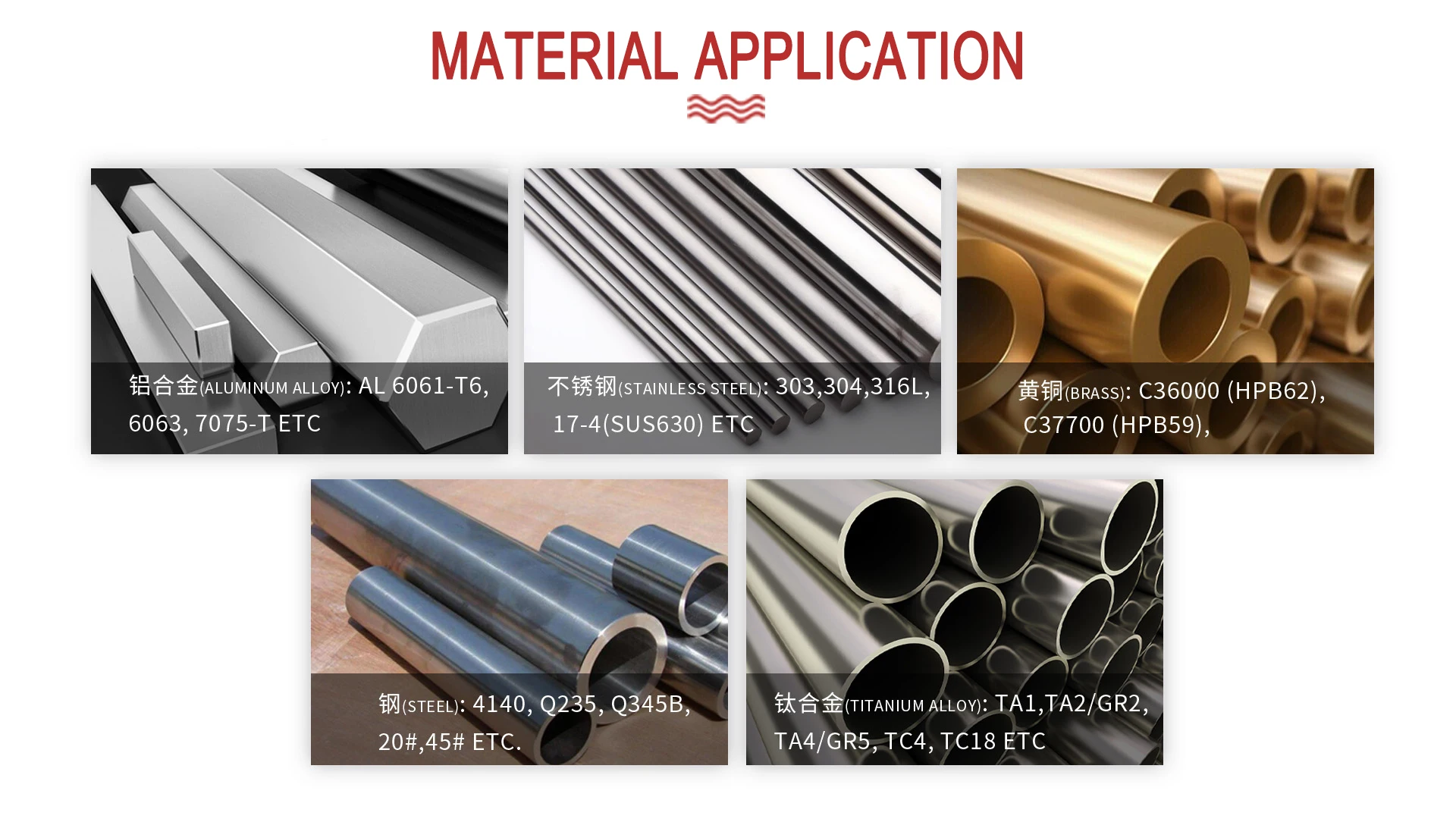

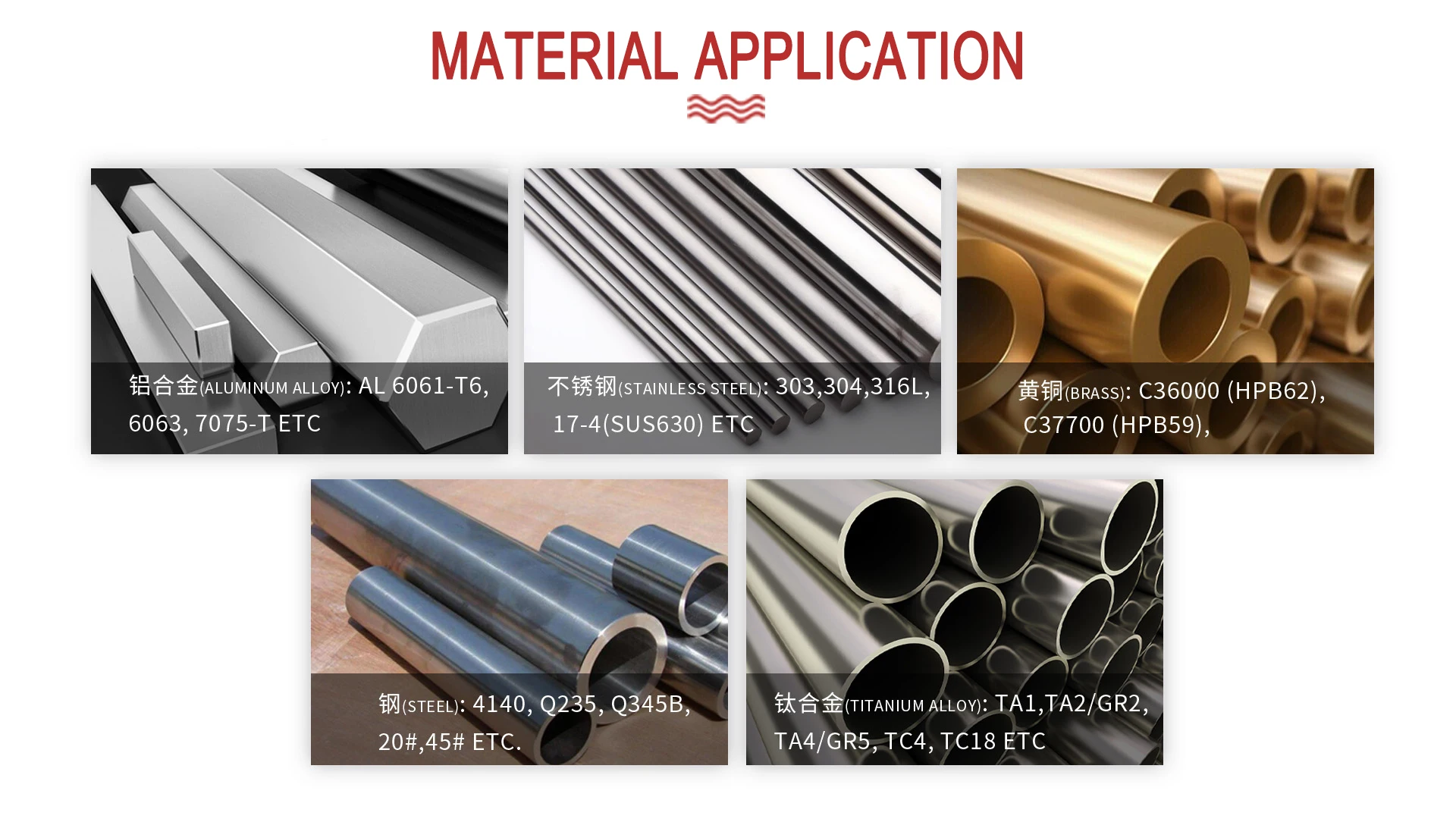

We select materials based on your bracket’s application scenario and load-bearing requirements, with all materials meeting international industrial standards:

Aluminum Alloy: 6061-T6, 6063 (lightweight, rust-resistant for commercial light shelves/furniture)

SPCC/Steel: Q235, Q345B, 45# (high load-bearing for industrial equipment brackets)

Stainless Steel: 304, 316L (corrosion-resistant for outdoor/kitchen shelving brackets)

We provide material certification for all orders, ensuring compliance with your industry’s quality requirements.

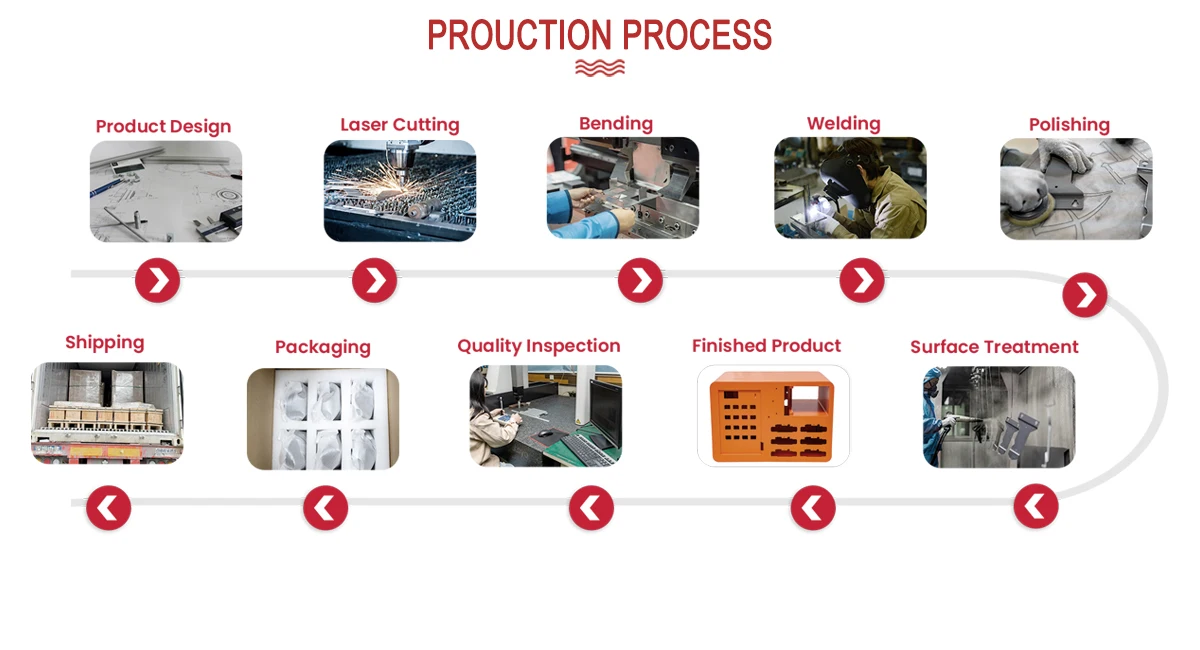

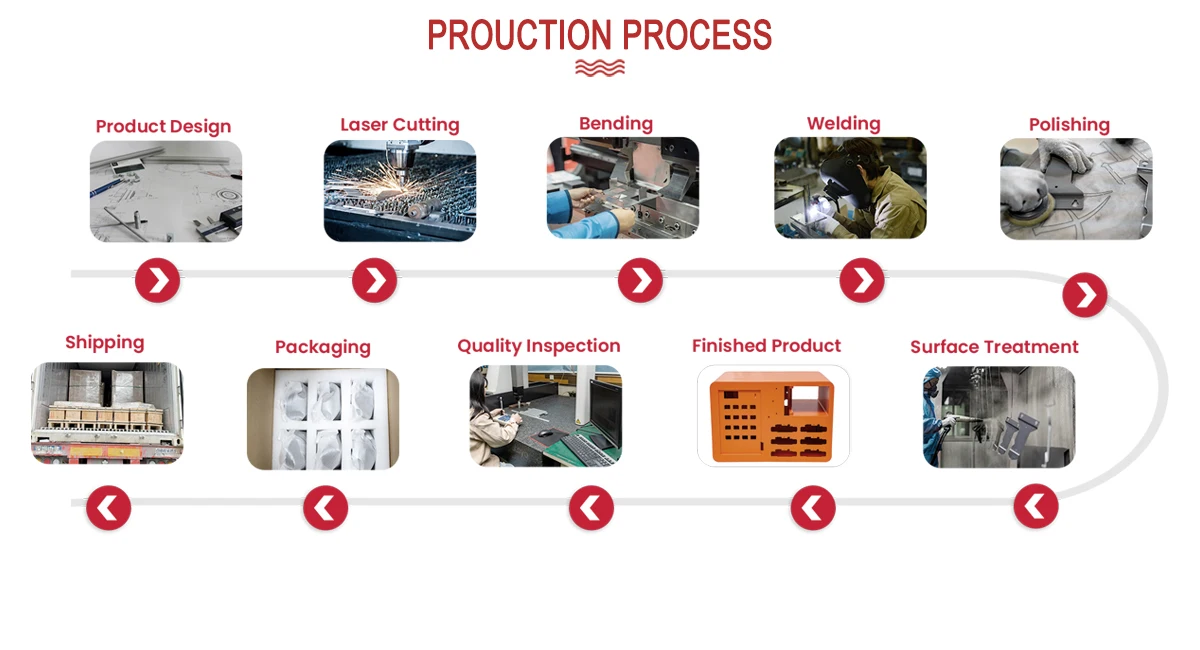

Product Design (drawing optimization for stamping feasibility)

Mold Making (custom stamping mold for your bracket design)

Precision Stamping (core forming for sheet metal brackets)

Bending & Shaping (custom angle forming for installation fit)

Edge Polishing & Deburring (ensuring safe and smooth surfaces)

Surface Treatment (electroplating, painting, powder coating per request)

Comprehensive Quality Inspection (dimensional, load-bearing, and surface testing)

Custom Packaging & Shipping (bulk packaging for mass production)

Our sheet metal light shelf stamping parts and custom brackets serve a wide range of ToB industries, with tailored solutions for different application scenarios:

Furniture Manufacturing: Shelf brackets for home/commercial furniture, cabinet support brackets

Industrial Equipment Production: Structural brackets for machinery, equipment mounting brackets

Commercial Shelving: Light shelf brackets for retail stores, supermarkets, and display stands

Warehousing & Logistics: Storage rack brackets, pallet support brackets

Lighting Equipment: Mounting brackets for commercial light fixtures, shelf light brackets

Building Decoration: Custom metal brackets for interior decoration and structural support

We offer full OEM/ODM customization for custom sheet metal brackets to meet your unique design and production needs. For OEM projects, we strictly follow your 2D/3D drawings for mass stamping production, ensuring consistent quality and on-time delivery for bulk orders. For ODM projects, our engineering team collaborates with you to design brackets optimized for stamping efficiency, load-bearing performance, and installation convenience, providing design revisions and sample testing to perfect your product. We support small-batch custom trials (MOQ 1) for new designs and offer flexible production capacity to scale with your order volume, from prototype to mass production. Our customization also covers surface treatment and packaging, with brand labeling options available for your finished products.

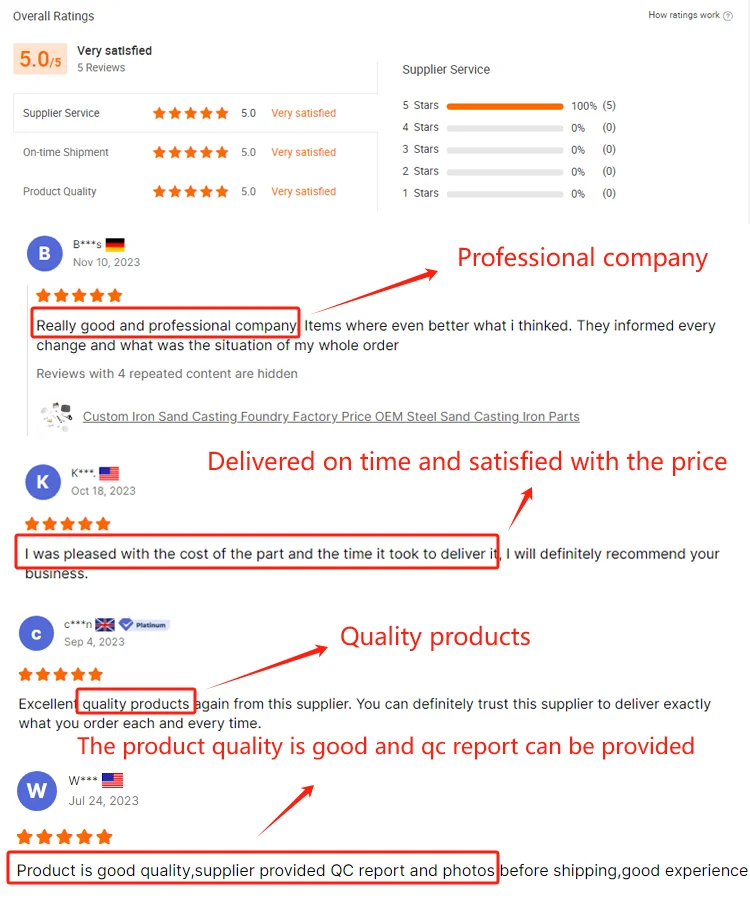

We implement a strict multi-stage quality control system for all sheet metal stamping parts, ensuring reliable performance for your products:

ISO9001 certified production line with standardized operating procedures

100% dimensional inspection for all stamping parts (using precision measuring tools)

Load-bearing testing for heavy-duty brackets to meet your application requirements

Professional QC report and product photos provided before shipment

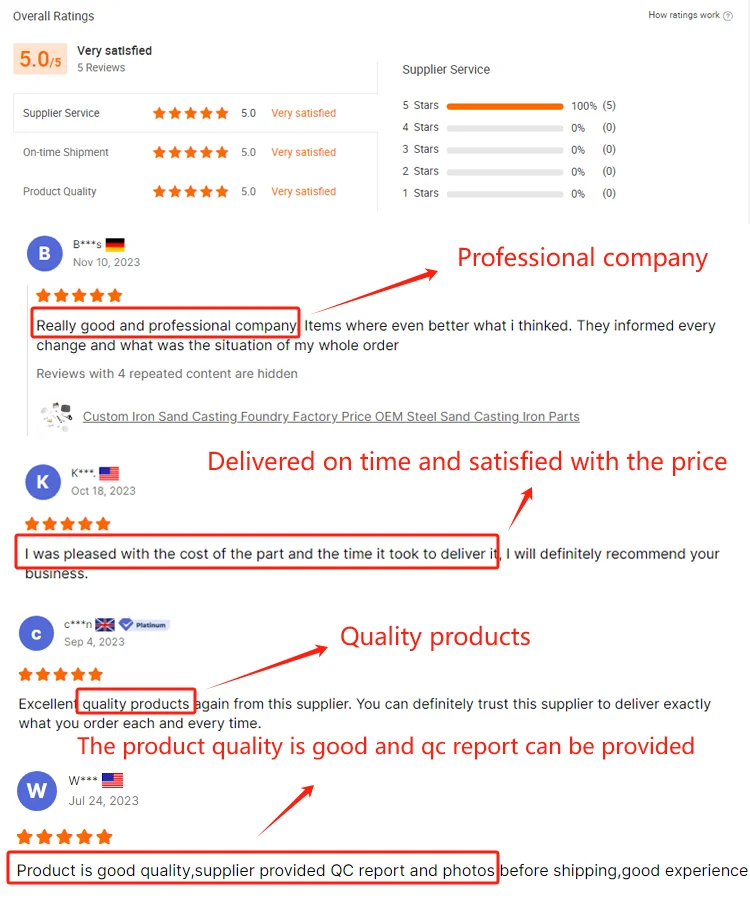

5.0/5 customer rating for product quality, on-time shipment, and after-sales service

Over 5000 global long-term partners, with consistent quality feedback for our stamping parts

We also offer a quality warranty for bulk orders, with replacement for non-conforming products at no additional cost.

For bulk stamping orders (1000+ pieces), lead time is 5-10 working days; lead time for small-batch custom orders is 3-5 working days, with expedited production available upon request.

Yes, our professional mold design team creates custom stamping molds for your exclusive bracket design, with mold cost details provided in the initial quote and mold reuse for future orders.

Absolutely, we provide corrosion-resistant surface treatments such as galvanizing, powder coating, and stainless steel passivation for outdoor/ humid environment brackets, enhancing durability and service life.

We conduct material strength testing and prototype load-bearing testing before mass production, optimizing the bracket’s thickness and structure based on test results to meet your specified load-bearing requirements.

Our custom sheet metal brackets and precision stamping sheet metal bracket for industrial use are high-strength structural components designed for ToB clients in furniture manufacturing, industrial equipment production, and commercial shelving industries. As a leading sheet metal stamping manufacturer with 16 years of experience, we craft SPCC steel sheet metal shelf brackets and aluminum light shelf parts with exceptional precision and durability, delivering robust support and seamless integration for various installation scenarios. Our stamping parts feature uniform thickness, smooth edges, and customizable hole spacing, making them the ideal solution for OEM/ODM projects requiring reliable structural brackets. Whether for heavy-duty industrial equipment, commercial light shelves, or custom furniture, our custom aluminum light shelf stamping parts balance cost-efficiency and performance, meeting the strict quality standards of bulk production and custom design projects alike.

High-Precision Stamping Technology: Our stamping process achieves ±0.0002in tolerance, ensuring consistent dimensions for mass-produced brackets and perfect fit for custom designs. Cost-Effective Mass Production: With advanced automated stamping lines, we reduce unit costs for bulk orders while maintaining high quality, ideal for large-scale manufacturing clients. Versatile Material Compatibility: We support stamping for aluminum, SPCC, steel, and stainless steel, with tailored processing for different material properties (e.g., lightweight aluminum for shelves, high-strength steel for industrial brackets). 7×24H Drawing & Quotation Service: Our engineering team reviews your custom bracket drawings within 2 hours, providing professional manufacturability suggestions and detailed cost quotes. One-Stop Procurement Solution: From stamping and bending to surface treatment and packaging, we offer end-to-end services to streamline your supply chain and reduce procurement costs.

Specification | Details |

Core Material | Aluminum, SPCC, Steel, 304/316L stainless steel (customizable) |

Size & Design | Fully customized based on customer’s 2D/3D drawings (bracket length, thickness, hole spacing) |

Model Type | OEM/ODM |

Minimum Order Quantity (MOQ) | 1 piece |

Machining Tolerance | ±0.0002in |

Stamping Technology | Precision cold stamping (for thin sheet) / hot stamping (for heavy-duty steel) |

Certification | ISO9001, material certification, QC inspection report |

We select materials based on your bracket’s application scenario and load-bearing requirements, with all materials meeting international industrial standards:

Aluminum Alloy: 6061-T6, 6063 (lightweight, rust-resistant for commercial light shelves/furniture)

SPCC/Steel: Q235, Q345B, 45# (high load-bearing for industrial equipment brackets)

Stainless Steel: 304, 316L (corrosion-resistant for outdoor/kitchen shelving brackets)

We provide material certification for all orders, ensuring compliance with your industry’s quality requirements.

Product Design (drawing optimization for stamping feasibility)

Mold Making (custom stamping mold for your bracket design)

Precision Stamping (core forming for sheet metal brackets)

Bending & Shaping (custom angle forming for installation fit)

Edge Polishing & Deburring (ensuring safe and smooth surfaces)

Surface Treatment (electroplating, painting, powder coating per request)

Comprehensive Quality Inspection (dimensional, load-bearing, and surface testing)

Custom Packaging & Shipping (bulk packaging for mass production)

Our sheet metal light shelf stamping parts and custom brackets serve a wide range of ToB industries, with tailored solutions for different application scenarios:

Furniture Manufacturing: Shelf brackets for home/commercial furniture, cabinet support brackets

Industrial Equipment Production: Structural brackets for machinery, equipment mounting brackets

Commercial Shelving: Light shelf brackets for retail stores, supermarkets, and display stands

Warehousing & Logistics: Storage rack brackets, pallet support brackets

Lighting Equipment: Mounting brackets for commercial light fixtures, shelf light brackets

Building Decoration: Custom metal brackets for interior decoration and structural support

We offer full OEM/ODM customization for custom sheet metal brackets to meet your unique design and production needs. For OEM projects, we strictly follow your 2D/3D drawings for mass stamping production, ensuring consistent quality and on-time delivery for bulk orders. For ODM projects, our engineering team collaborates with you to design brackets optimized for stamping efficiency, load-bearing performance, and installation convenience, providing design revisions and sample testing to perfect your product. We support small-batch custom trials (MOQ 1) for new designs and offer flexible production capacity to scale with your order volume, from prototype to mass production. Our customization also covers surface treatment and packaging, with brand labeling options available for your finished products.

We implement a strict multi-stage quality control system for all sheet metal stamping parts, ensuring reliable performance for your products:

ISO9001 certified production line with standardized operating procedures

100% dimensional inspection for all stamping parts (using precision measuring tools)

Load-bearing testing for heavy-duty brackets to meet your application requirements

Professional QC report and product photos provided before shipment

5.0/5 customer rating for product quality, on-time shipment, and after-sales service

Over 5000 global long-term partners, with consistent quality feedback for our stamping parts

We also offer a quality warranty for bulk orders, with replacement for non-conforming products at no additional cost.

For bulk stamping orders (1000+ pieces), lead time is 5-10 working days; lead time for small-batch custom orders is 3-5 working days, with expedited production available upon request.

Yes, our professional mold design team creates custom stamping molds for your exclusive bracket design, with mold cost details provided in the initial quote and mold reuse for future orders.

Absolutely, we provide corrosion-resistant surface treatments such as galvanizing, powder coating, and stainless steel passivation for outdoor/ humid environment brackets, enhancing durability and service life.

We conduct material strength testing and prototype load-bearing testing before mass production, optimizing the bracket’s thickness and structure based on test results to meet your specified load-bearing requirements.