Introducing the cutting-edge realm of custom steel sheet metal processing through automatic laser cutting and stamping parts. In today's dynamic industrial landscape, precision and efficiency are paramount, driving the demand for innovative solutions in metal fabrication. Leveraging advanced technologies, such as automatic laser cutting and stamping, manufacturers can achieve unparalleled accuracy and consistency in shaping steel sheet metal components. This fusion of automation and craftsmanship enables the creation of intricate designs with minimal material waste, offering cost-effective solutions for a diverse range of applications. From automotive to aerospace, electronics to architecture, the versatility of custom steel sheet metal processing empowers industries to push the boundaries of design while meeting the highest standards of quality and performance. With its ability to seamlessly integrate with CAD/CAM software and adapt to varying production volumes, this cutting-edge approach revolutionizes the manufacturing landscape, driving innovation and unlocking new possibilities in product development and engineering.

| Material: | |

|---|---|

| Size: | |

| Availability: | |

| Quantity: | |

OEM/ODM

Custom steel sheet metal processing is the core of high-precision industrial component manufacturing, and our automatic laser cutting stamping parts service redefines the standard of metal fabrication for global ToB clients. Leveraging state-of-the-art automatic laser cutting technology and precision stamping equipment, we deliver high precision steel stamping components with unparalleled accuracy, minimal material waste and consistent quality. This service is tailored for industrial clients requiring custom steel sheet metal parts for mass production or small-batch customization, seamlessly integrating with CAD/CAM software to meet the most intricate design requirements. Whether it’s complex geometric steel components or standard stamping parts, our OEM laser cut steel sheet metal parts solution balances efficiency and precision, making it the first choice for automotive, aerospace and electronics industries pursuing high-quality metal fabrication.

Our professional engineering team provides round-the-clock drawing review and technical consultation for automatic laser cutting stamping parts. Clients receive a detailed quotation within 2 hours for all custom steel sheet metal processing requests, eliminating waiting time for project initiation.

We achieve a tolerance of ±0.0002in for high precision steel stamping components—10x higher precision than industry peers—ensuring perfect fit and performance of laser cut and stamped steel parts in high-end industrial applications.

With automated production lines and optimized process scheduling, we cut the production cycle of custom steel sheet metal processing by up to 50%, supporting clients in accelerating product launch and market response.

We offer a full-range one-stop service from material selection, laser cutting/stamping to surface treatment and shipping, reducing clients’ procurement costs and supply chain management complexity.

Parameter | Detail |

Core Processing | Automatic Laser Cutting, Precision Stamping |

Main Material | Aluminum; SPCC; Steel (4140, Q235, Q345B, 20#, 45#) |

Size | Fully customized based on client’s 2D/3D drawing |

Tolerance | ±0.0002in (10x tighter than industry standard) |

MOQ | 1 piece (support small-batch custom processing) |

Model | OEM/ODM |

Surface Treatment | Customizable (polishing, plating, painting, etc.) |

Delivery Term | Negotiable (air/sea/express for global shipping) |

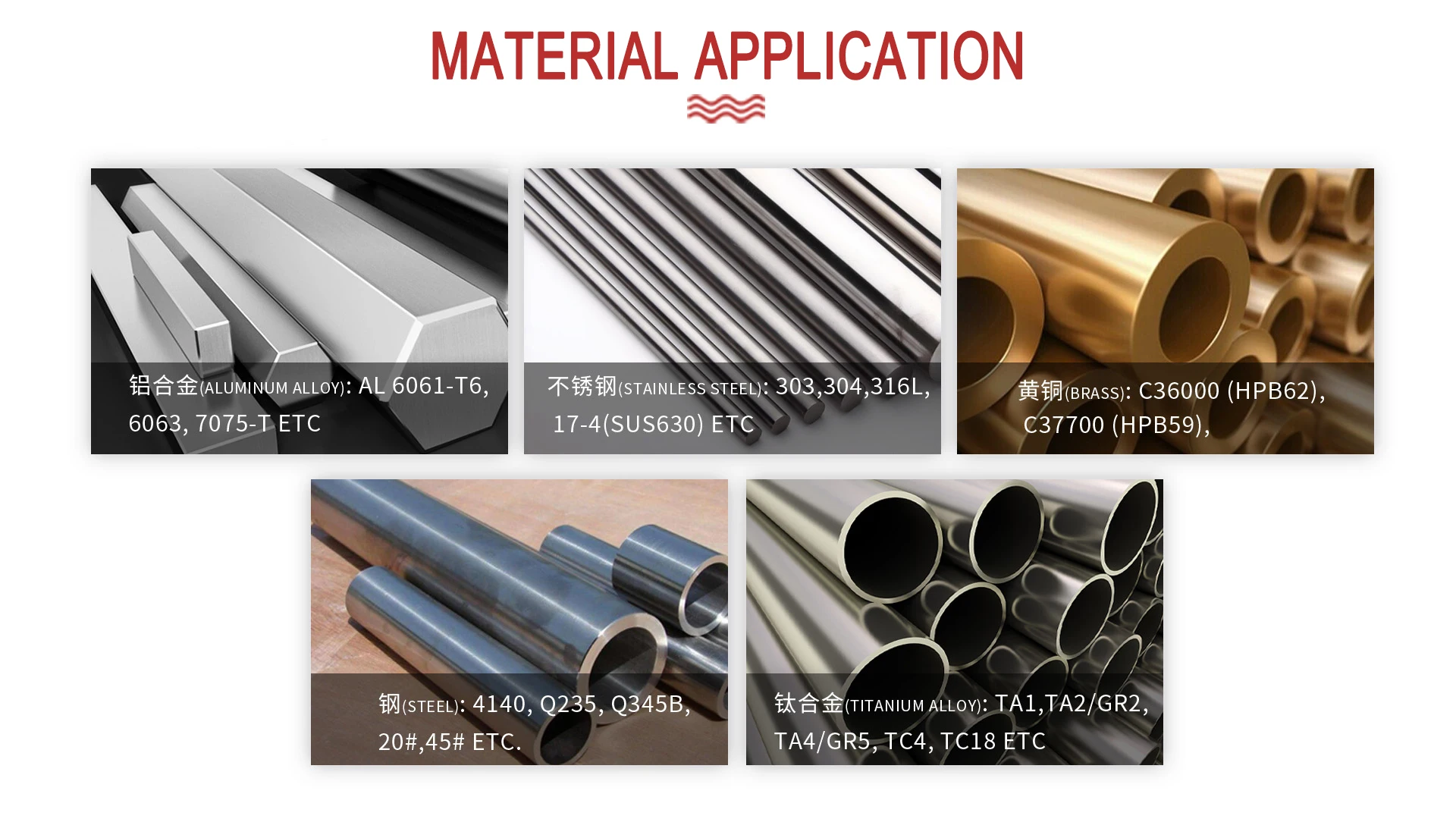

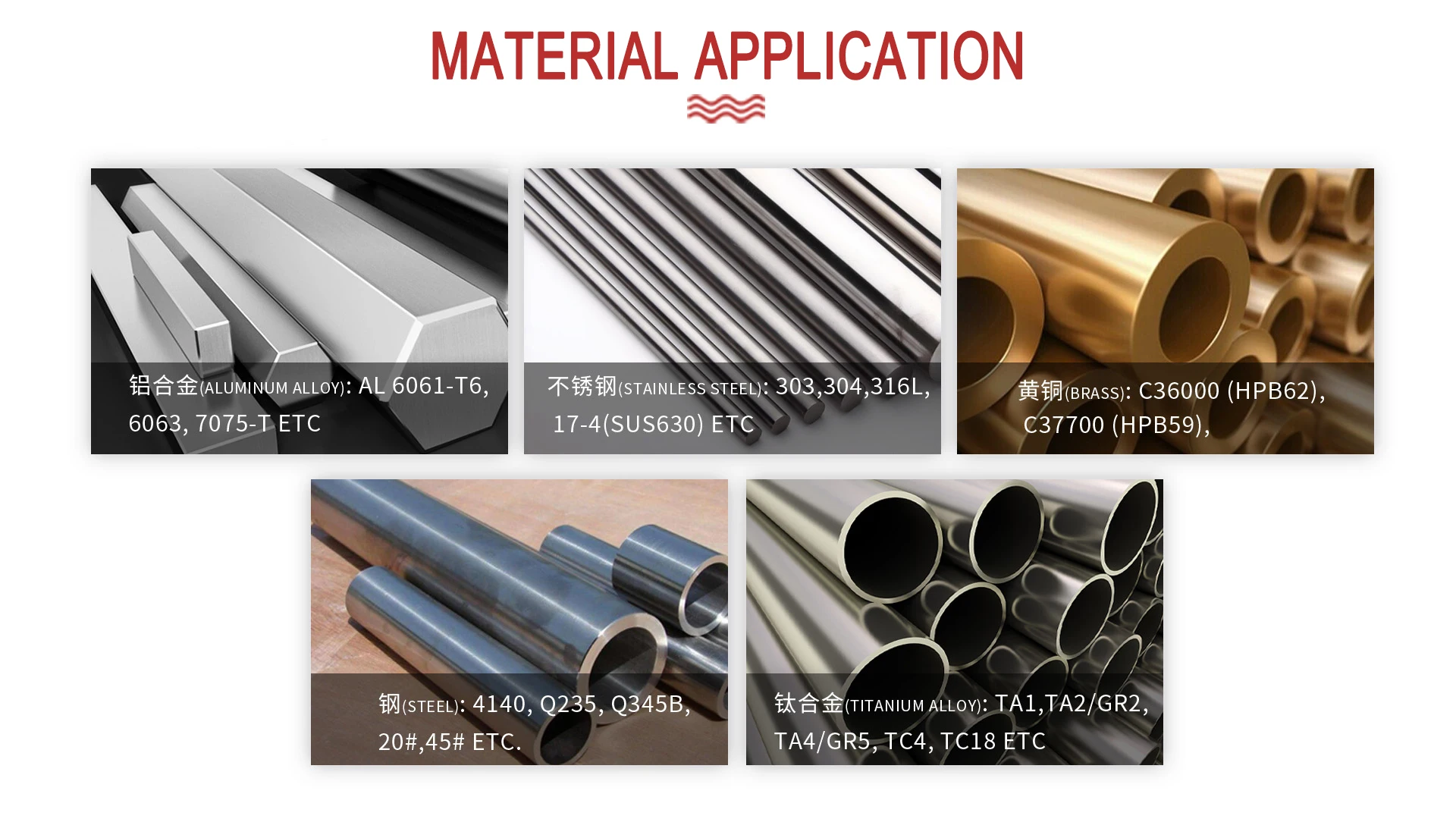

We select high-quality industrial materials for custom steel sheet metal processing, including carbon steel (Q235, Q345B), alloy steel (4140), aluminum alloy (6061-T6, 6063) and stainless steel (304, 316L). All materials come with official certification to ensure mechanical properties and durability meet industrial standards.

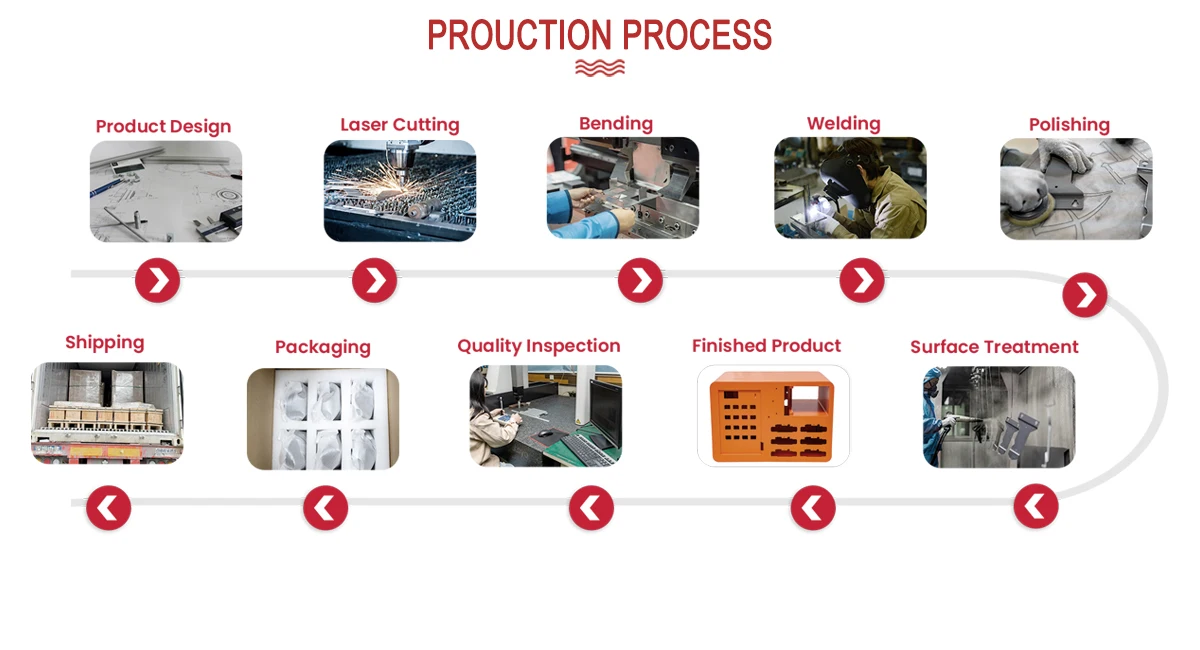

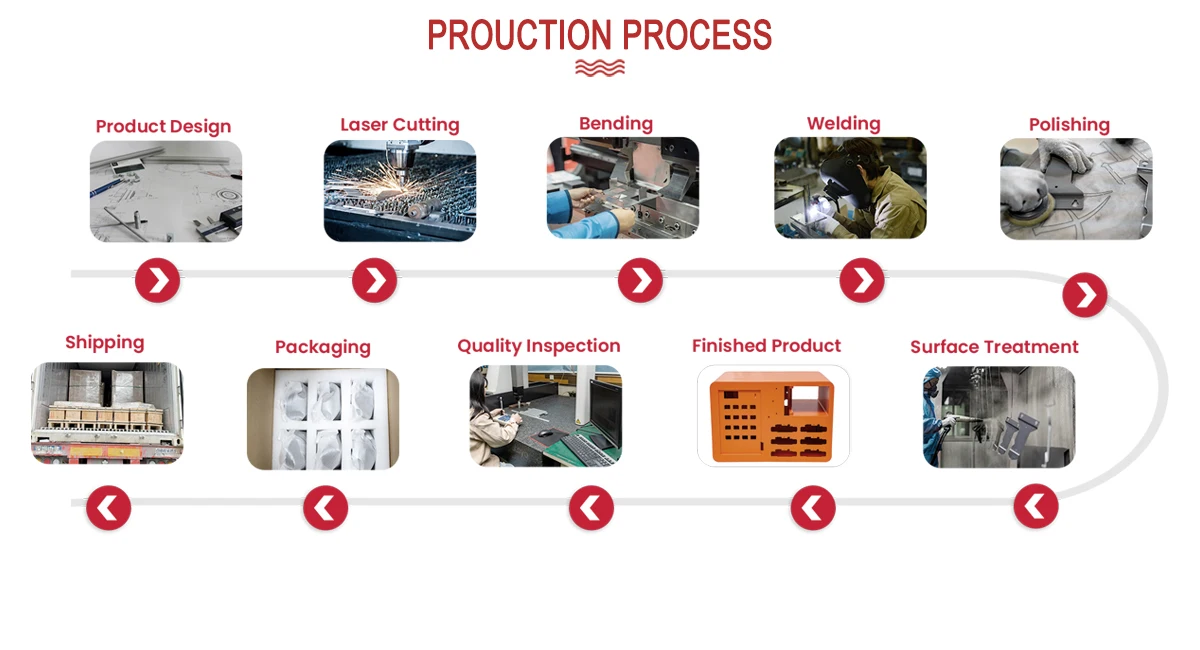

Product Design: Deep integration with CAD/CAM for automatic laser cutting path optimization;

Automatic Laser Cutting: High-speed, high-precision cutting of steel sheets with minimal thermal deformation;

Precision Stamping: Forming steel components with customized dies for consistent shape and size;

Polishing & Surface Treatment: Deburring and custom surface processing to enhance corrosion resistance;

Quality Inspection: Multi-dimensional testing of dimensions, precision and material performance;

Packaging & Shipping: Anti-collision packaging for global delivery with real-time logistics tracking.

Our automatic laser cutting stamping parts service serves a wide range of high-precision industrial sectors:

Automotive Industry: Custom steel stamping parts for chassis, engine and electrical systems;

Aerospace Industry: High-precision laser cut steel components for aircraft and aerospace equipment;

Electronics Industry: Miniature steel stamping parts for electronic enclosures and connectors;

Architectural Hardware: Custom steel structural parts for building mechanical systems.

We specialize in OEM laser cut steel sheet metal parts and ODM custom development for over 16 years. For OEM clients, we fully follow the provided 2D/3D drawings to complete custom steel sheet metal processing with 1:1 precision. For ODM clients, our engineering team provides professional design optimization suggestions for laser cutting and stamping, combining material characteristics and production processes to improve part performance and reduce manufacturing costs. We support small-batch customization (MOQ=1) and mass production, with flexible production scheduling to meet different client demands.

16 years of professional experience in custom steel sheet metal processing with ISO-certified production lines;

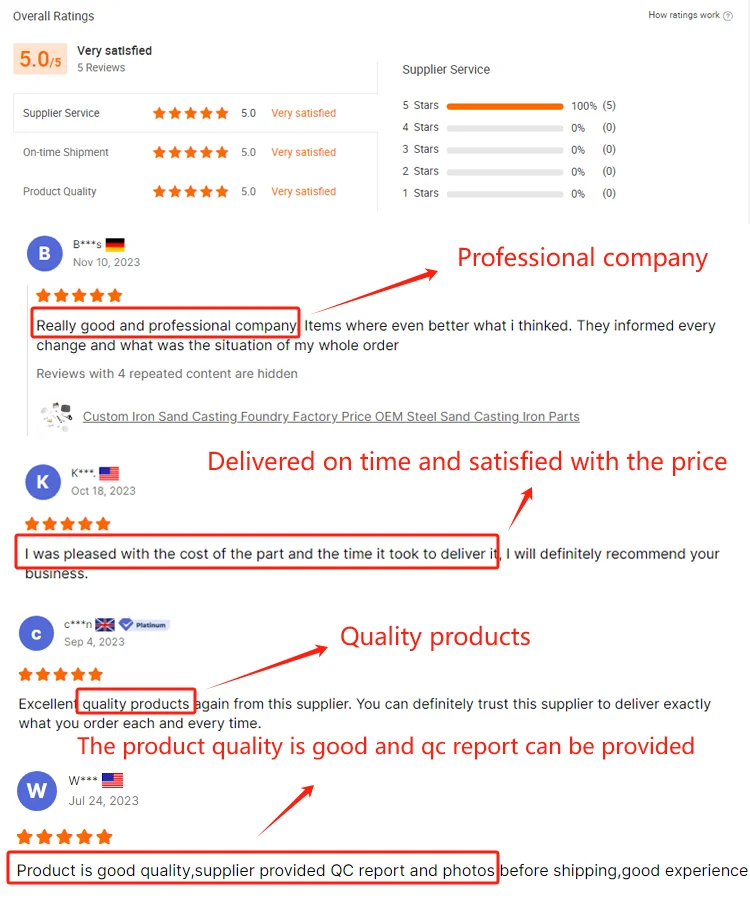

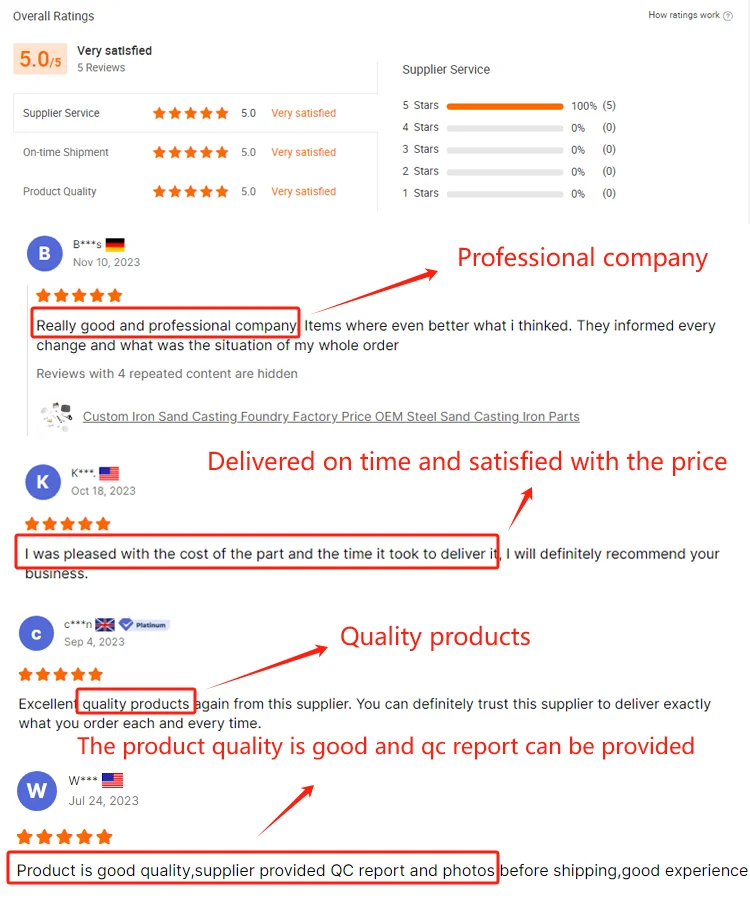

Over 5000 global cooperative partners, maintaining a 5.0/5 full-score evaluation for product quality;

Comprehensive quality inspection: material certification, dimensional testing and precision report for each batch of laser cut steel stamping parts;

Pre-shipment QC report and real product photos provided to clients for confirmation.

We support all mainstream industrial formats including STEP, IGES, CAD, PDF and DWG, with professional engineers providing drawing compatibility review.

For small-batch orders (1-100 pieces), the production lead time is 3-5 working days; mass production lead time is negotiable based on order quantity.

Yes, we provide official material certification, conformity certificate and detailed inspection report for all steel sheet metal parts to meet clients’ industrial certification requirements.

Custom steel sheet metal processing is the core of high-precision industrial component manufacturing, and our automatic laser cutting stamping parts service redefines the standard of metal fabrication for global ToB clients. Leveraging state-of-the-art automatic laser cutting technology and precision stamping equipment, we deliver high precision steel stamping components with unparalleled accuracy, minimal material waste and consistent quality. This service is tailored for industrial clients requiring custom steel sheet metal parts for mass production or small-batch customization, seamlessly integrating with CAD/CAM software to meet the most intricate design requirements. Whether it’s complex geometric steel components or standard stamping parts, our OEM laser cut steel sheet metal parts solution balances efficiency and precision, making it the first choice for automotive, aerospace and electronics industries pursuing high-quality metal fabrication.

Our professional engineering team provides round-the-clock drawing review and technical consultation for automatic laser cutting stamping parts. Clients receive a detailed quotation within 2 hours for all custom steel sheet metal processing requests, eliminating waiting time for project initiation.

We achieve a tolerance of ±0.0002in for high precision steel stamping components—10x higher precision than industry peers—ensuring perfect fit and performance of laser cut and stamped steel parts in high-end industrial applications.

With automated production lines and optimized process scheduling, we cut the production cycle of custom steel sheet metal processing by up to 50%, supporting clients in accelerating product launch and market response.

We offer a full-range one-stop service from material selection, laser cutting/stamping to surface treatment and shipping, reducing clients’ procurement costs and supply chain management complexity.

Parameter | Detail |

Core Processing | Automatic Laser Cutting, Precision Stamping |

Main Material | Aluminum; SPCC; Steel (4140, Q235, Q345B, 20#, 45#) |

Size | Fully customized based on client’s 2D/3D drawing |

Tolerance | ±0.0002in (10x tighter than industry standard) |

MOQ | 1 piece (support small-batch custom processing) |

Model | OEM/ODM |

Surface Treatment | Customizable (polishing, plating, painting, etc.) |

Delivery Term | Negotiable (air/sea/express for global shipping) |

We select high-quality industrial materials for custom steel sheet metal processing, including carbon steel (Q235, Q345B), alloy steel (4140), aluminum alloy (6061-T6, 6063) and stainless steel (304, 316L). All materials come with official certification to ensure mechanical properties and durability meet industrial standards.

Product Design: Deep integration with CAD/CAM for automatic laser cutting path optimization;

Automatic Laser Cutting: High-speed, high-precision cutting of steel sheets with minimal thermal deformation;

Precision Stamping: Forming steel components with customized dies for consistent shape and size;

Polishing & Surface Treatment: Deburring and custom surface processing to enhance corrosion resistance;

Quality Inspection: Multi-dimensional testing of dimensions, precision and material performance;

Packaging & Shipping: Anti-collision packaging for global delivery with real-time logistics tracking.

Our automatic laser cutting stamping parts service serves a wide range of high-precision industrial sectors:

Automotive Industry: Custom steel stamping parts for chassis, engine and electrical systems;

Aerospace Industry: High-precision laser cut steel components for aircraft and aerospace equipment;

Electronics Industry: Miniature steel stamping parts for electronic enclosures and connectors;

Architectural Hardware: Custom steel structural parts for building mechanical systems.

We specialize in OEM laser cut steel sheet metal parts and ODM custom development for over 16 years. For OEM clients, we fully follow the provided 2D/3D drawings to complete custom steel sheet metal processing with 1:1 precision. For ODM clients, our engineering team provides professional design optimization suggestions for laser cutting and stamping, combining material characteristics and production processes to improve part performance and reduce manufacturing costs. We support small-batch customization (MOQ=1) and mass production, with flexible production scheduling to meet different client demands.

16 years of professional experience in custom steel sheet metal processing with ISO-certified production lines;

Over 5000 global cooperative partners, maintaining a 5.0/5 full-score evaluation for product quality;

Comprehensive quality inspection: material certification, dimensional testing and precision report for each batch of laser cut steel stamping parts;

Pre-shipment QC report and real product photos provided to clients for confirmation.

We support all mainstream industrial formats including STEP, IGES, CAD, PDF and DWG, with professional engineers providing drawing compatibility review.

For small-batch orders (1-100 pieces), the production lead time is 3-5 working days; mass production lead time is negotiable based on order quantity.

Yes, we provide official material certification, conformity certificate and detailed inspection report for all steel sheet metal parts to meet clients’ industrial certification requirements.