Introducing our custom sheet metal fabrication Diving Backplate – the epitome of durability, functionality, and personalized design for diving enthusiasts. Crafted with precision and expertise, our backplates are engineered to withstand the rigors of underwater exploration while offering a customizable platform for divers of all levels.

| Material: | |

|---|---|

| Size: | |

| Availability: | |

| Quantity: | |

OEM/ODM

Our custom laser cutting scuba diving backplate is a high-performance core component for scuba diving equipment, engineered exclusively for professional diving gear manufacturers and underwater exploration suppliers. Crafted with premium sheet metal and advanced fabrication techniques, this sheet bending aluminum diving backplate delivers unbeatable durability and ergonomic design to withstand the extreme pressure of deep-sea environments. Unlike standard diving backplates, our precision-machined parts feature reinforced attachment points and tailor-made shaping, ensuring a perfect fit with all diving buoyancy control devices (BCDs). Whether for recreational diving brands or professional underwater research equipment producers, this precision metal diving backplate for underwater exploration balances lightweight construction and structural strength, making it the ideal custom sheet metal solution for all diving equipment customization needs.

Ultra-Precision Machining: Our diving backplates achieve a tolerance of ±0.0002in, 10× tighter than industry standards, ensuring seamless compatibility with diving equipment components. 7×24H Professional Technical Support: 24 online engineers review your custom drawings and provide detailed quotes within 2 hours, streamlining your procurement and customization process. 50% Faster Lead Times: With our self-owned factory and integrated production line, we cut production cycle times by up to 50% while maintaining strict quality control. One-Stop Customization Service: From material selection to surface treatment, we offer end-to-end solutions for diving backplate customization, eliminating the need for multiple suppliers. Proven Underwater Durability: All backplates undergo rigorous pressure and corrosion testing, meeting the performance requirements of deep-sea diving environments.

Specification | Details |

Core Material | Aluminum, SPCC, Steel (customizable) |

Size & Shape | Fully customized based on customer’s 2D/3D drawings |

Model Type | OEM/ODM |

Minimum Order Quantity (MOQ) | 1 piece |

Machining Tolerance | ±0.0002in |

Surface Treatment | Polishing, welding, customized coating (per request) |

Certification | ISO9001, material certification, conformity certificate |

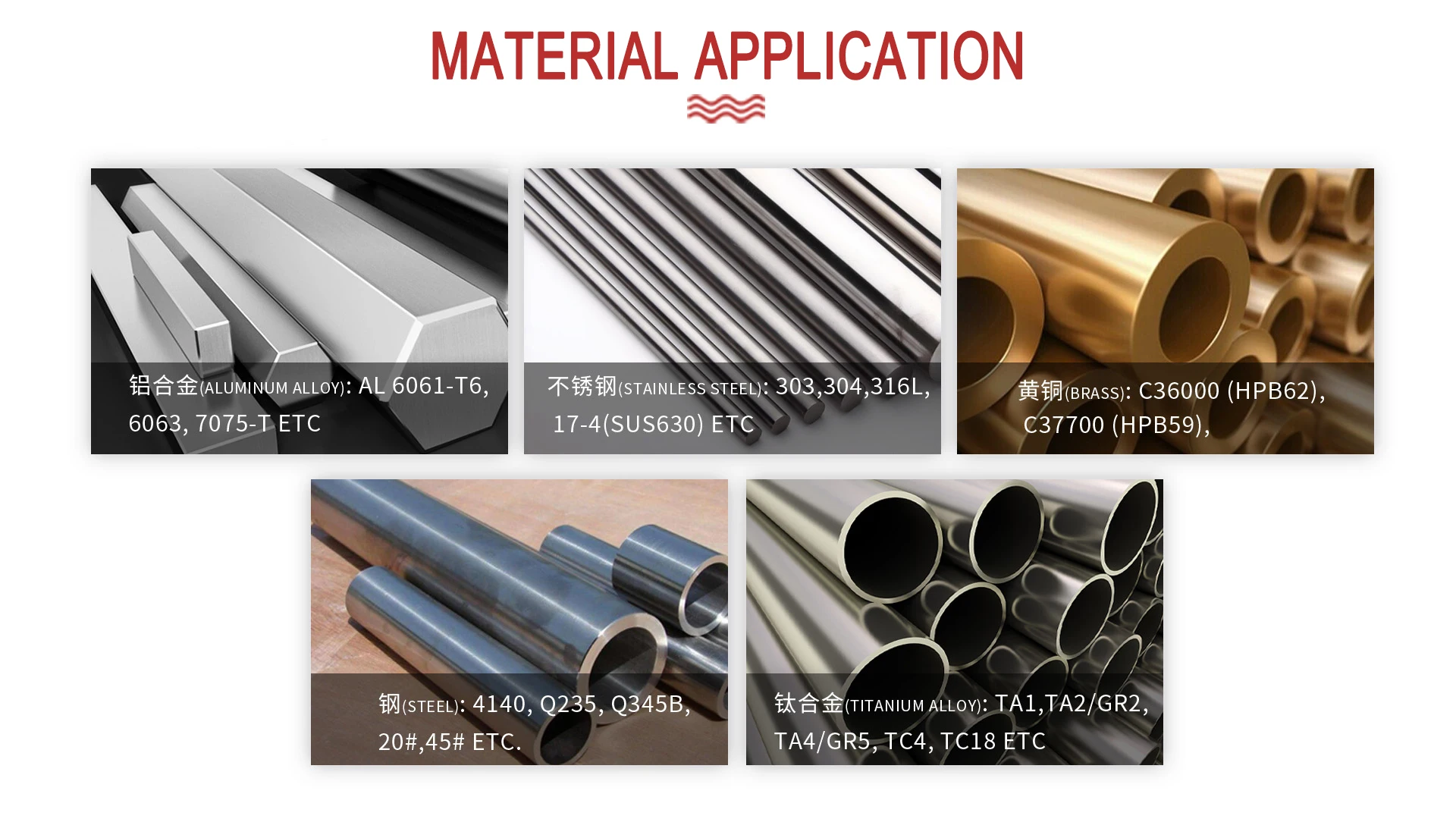

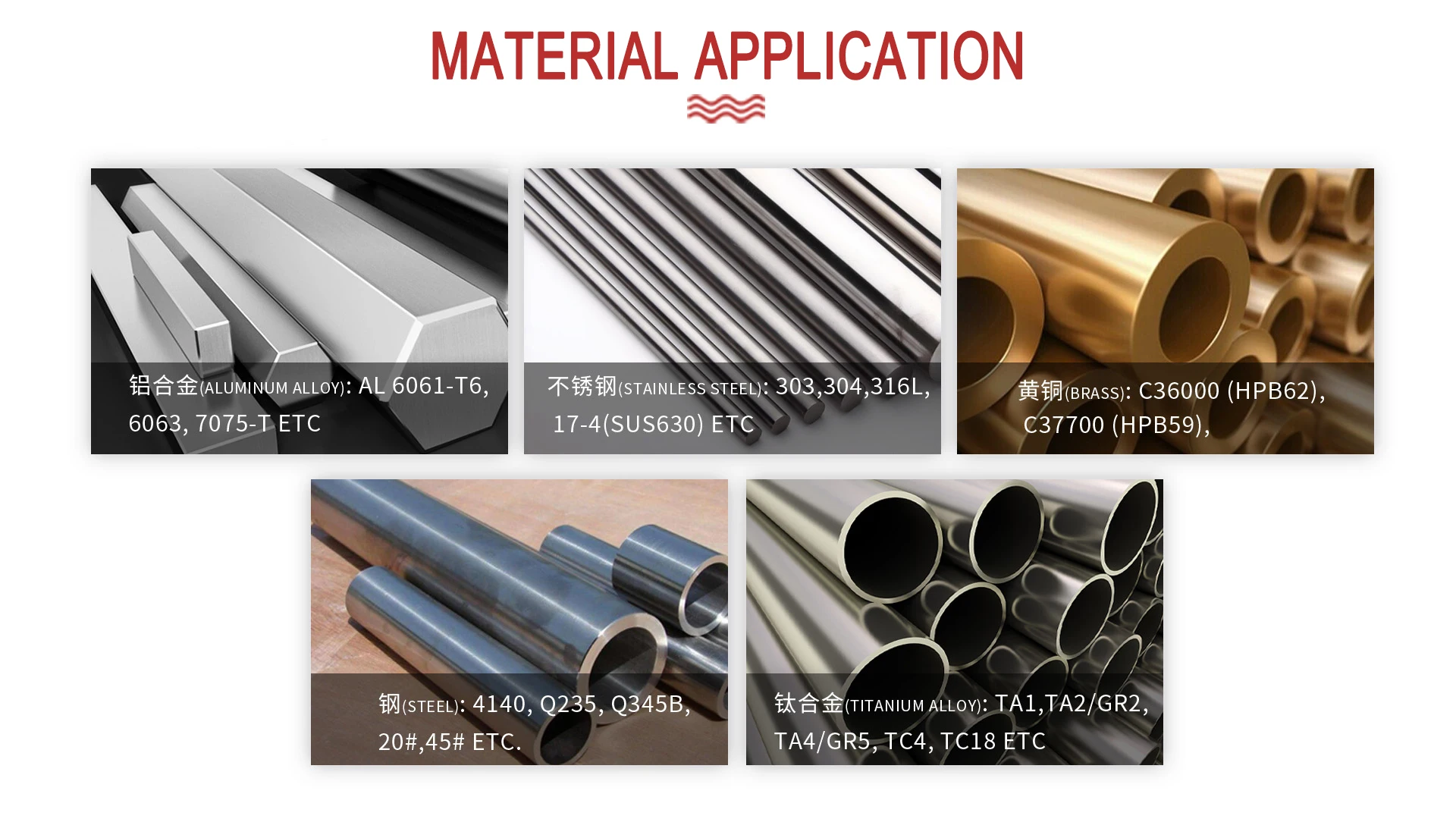

We select marine-grade materials for optimal underwater performance, including:

Aluminum Alloy: 6061-T6, 6063, 7075-T (lightweight, corrosion-resistant)

Stainless Steel: 304, 316L (high pressure resistance for deep diving)

Steel: Q235, Q345B (for heavy-duty professional diving equipment)

All materials come with official certification to ensure compliance with international diving equipment standards.

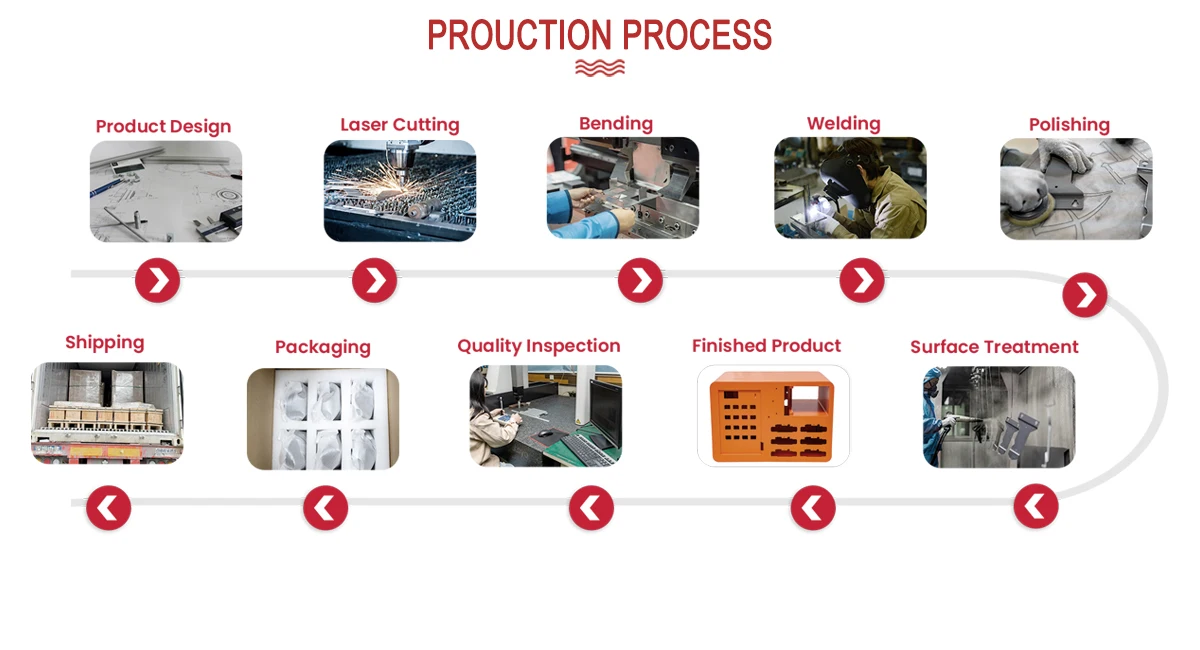

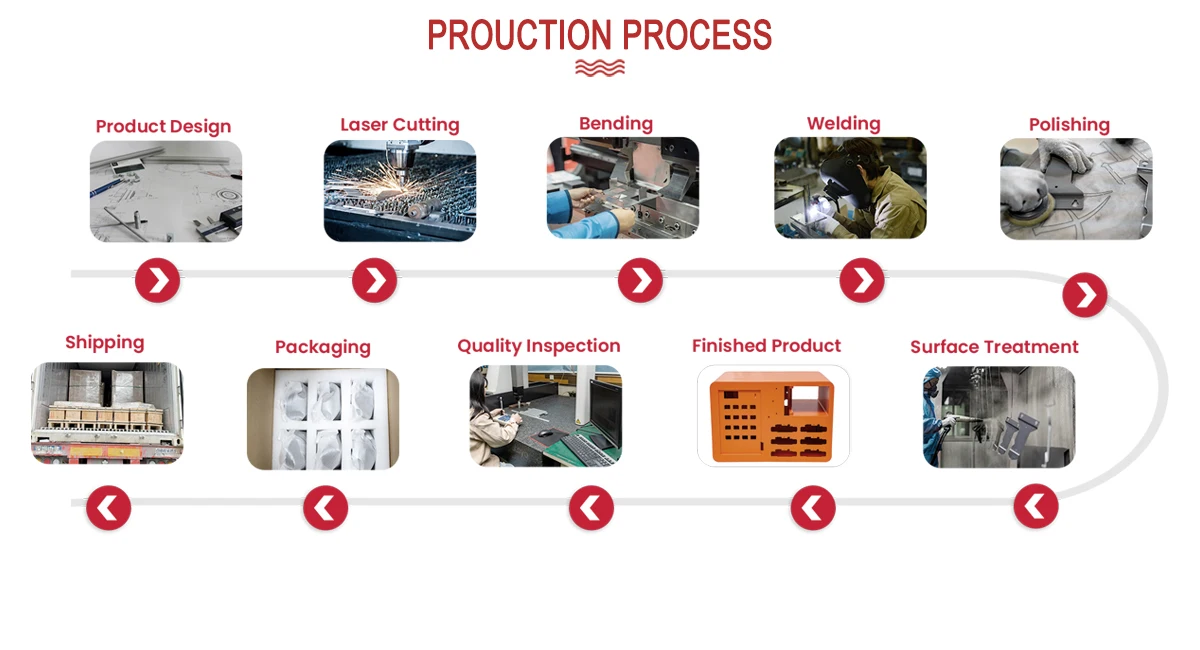

Product Design (drawing verification & optimization)

Laser Cutting (precision shaping of sheet metal blanks)

Sheet Bending (ergonomic forming for diving fit)

Welding & Reinforcement (strengthening attachment points)

Polishing & Surface Treatment (corrosion protection)

Strict Quality Inspection (pressure & dimensional testing)

Packaging & Shipping (shockproof packaging for international delivery)

Our sheet metal diving backplate is widely used by ToB clients in the diving equipment industry, including:

Scuba diving gear manufacturers (BCD backplate assembly)

Underwater exploration equipment suppliers (professional research diving gear)

Diving training institution equipment providers (recreational diving gear)

Water sports equipment brands (custom diving gear lines)

Marine engineering equipment companies (underwater operation gear)

We specialize in OEM/ODM customization for aluminum scuba backplate with 16 years of sheet metal fabrication experience. Our engineering team optimizes your drawings for manufacturability and cost-efficiency, offering customizations such as unique hole positioning, ergonomic curvature, and material combination. We support small-batch custom trials (MOQ 1) and mass production, with consistent quality across all order sizes. For ODM projects, we provide design suggestions based on your product positioning and diving environment requirements, creating exclusive backplate solutions for your brand.

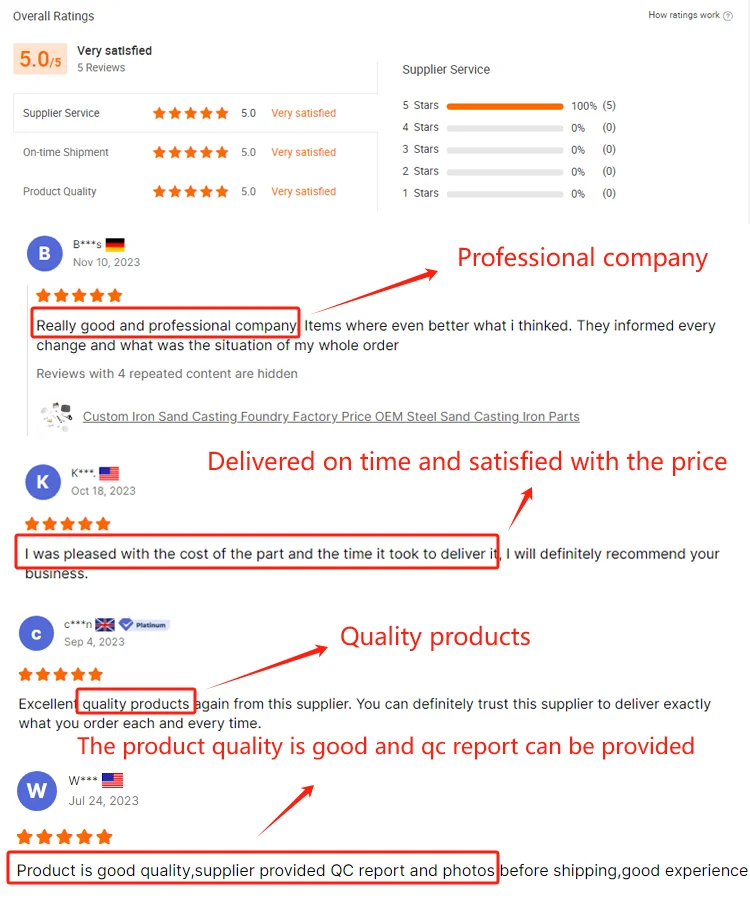

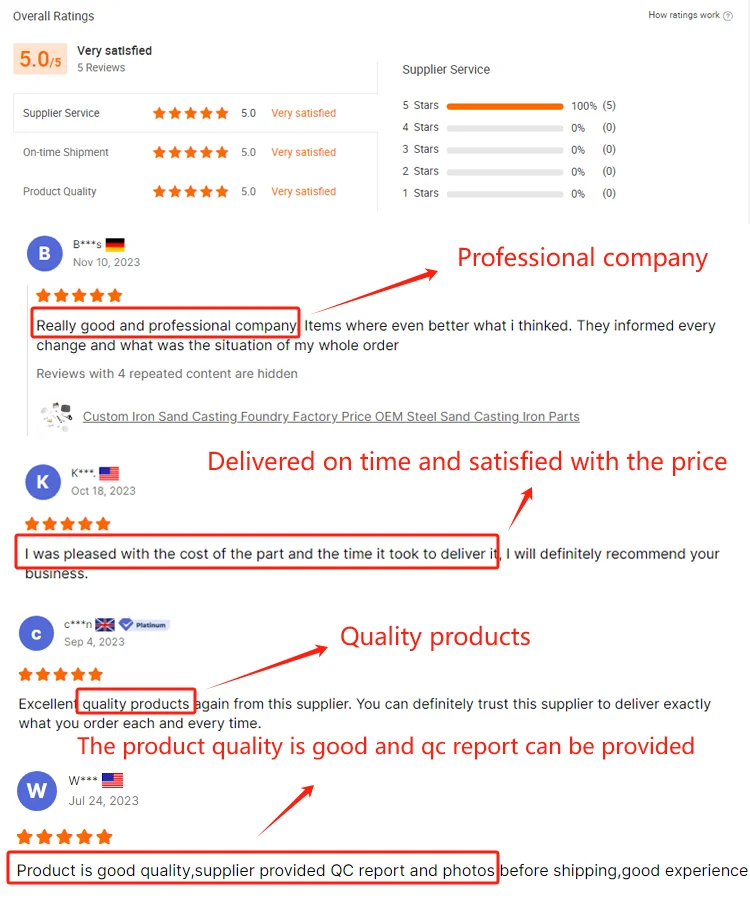

Quality is our core priority for all diving equipment parts:

ISO9001 certified production process with full traceability

100% dimensional and performance testing before shipment

Professional QC reports and product photos provided for every order

5.0/5 overall customer rating for product quality and on-time shipment

Material certification and conformity certificates available on request

We have established long-term partnerships with over 5000 global clients, with zero quality complaints for our diving backplate products.

For small-batch orders (1-100 pieces), lead time is 3-7 working days; mass production lead time is negotiated based on order quantity, with fast production capacity to meet your delivery schedule.

Yes, we offer customized surface coatings such as anodizing and powder coating for enhanced marine corrosion resistance, tailored to your specific diving environment needs.

Absolutely, we produce sample backplates for your performance and assembly testing, with sample costs refundable upon mass production order confirmation.

We use CNC laser cutting and automated bending equipment, with a three-step inspection process (pre-production, in-production, post-production) to ensure 100% compliance with your drawing specifications.

Our custom laser cutting scuba diving backplate is a high-performance core component for scuba diving equipment, engineered exclusively for professional diving gear manufacturers and underwater exploration suppliers. Crafted with premium sheet metal and advanced fabrication techniques, this sheet bending aluminum diving backplate delivers unbeatable durability and ergonomic design to withstand the extreme pressure of deep-sea environments. Unlike standard diving backplates, our precision-machined parts feature reinforced attachment points and tailor-made shaping, ensuring a perfect fit with all diving buoyancy control devices (BCDs). Whether for recreational diving brands or professional underwater research equipment producers, this precision metal diving backplate for underwater exploration balances lightweight construction and structural strength, making it the ideal custom sheet metal solution for all diving equipment customization needs.

Ultra-Precision Machining: Our diving backplates achieve a tolerance of ±0.0002in, 10× tighter than industry standards, ensuring seamless compatibility with diving equipment components. 7×24H Professional Technical Support: 24 online engineers review your custom drawings and provide detailed quotes within 2 hours, streamlining your procurement and customization process. 50% Faster Lead Times: With our self-owned factory and integrated production line, we cut production cycle times by up to 50% while maintaining strict quality control. One-Stop Customization Service: From material selection to surface treatment, we offer end-to-end solutions for diving backplate customization, eliminating the need for multiple suppliers. Proven Underwater Durability: All backplates undergo rigorous pressure and corrosion testing, meeting the performance requirements of deep-sea diving environments.

Specification | Details |

Core Material | Aluminum, SPCC, Steel (customizable) |

Size & Shape | Fully customized based on customer’s 2D/3D drawings |

Model Type | OEM/ODM |

Minimum Order Quantity (MOQ) | 1 piece |

Machining Tolerance | ±0.0002in |

Surface Treatment | Polishing, welding, customized coating (per request) |

Certification | ISO9001, material certification, conformity certificate |

We select marine-grade materials for optimal underwater performance, including:

Aluminum Alloy: 6061-T6, 6063, 7075-T (lightweight, corrosion-resistant)

Stainless Steel: 304, 316L (high pressure resistance for deep diving)

Steel: Q235, Q345B (for heavy-duty professional diving equipment)

All materials come with official certification to ensure compliance with international diving equipment standards.

Product Design (drawing verification & optimization)

Laser Cutting (precision shaping of sheet metal blanks)

Sheet Bending (ergonomic forming for diving fit)

Welding & Reinforcement (strengthening attachment points)

Polishing & Surface Treatment (corrosion protection)

Strict Quality Inspection (pressure & dimensional testing)

Packaging & Shipping (shockproof packaging for international delivery)

Our sheet metal diving backplate is widely used by ToB clients in the diving equipment industry, including:

Scuba diving gear manufacturers (BCD backplate assembly)

Underwater exploration equipment suppliers (professional research diving gear)

Diving training institution equipment providers (recreational diving gear)

Water sports equipment brands (custom diving gear lines)

Marine engineering equipment companies (underwater operation gear)

We specialize in OEM/ODM customization for aluminum scuba backplate with 16 years of sheet metal fabrication experience. Our engineering team optimizes your drawings for manufacturability and cost-efficiency, offering customizations such as unique hole positioning, ergonomic curvature, and material combination. We support small-batch custom trials (MOQ 1) and mass production, with consistent quality across all order sizes. For ODM projects, we provide design suggestions based on your product positioning and diving environment requirements, creating exclusive backplate solutions for your brand.

Quality is our core priority for all diving equipment parts:

ISO9001 certified production process with full traceability

100% dimensional and performance testing before shipment

Professional QC reports and product photos provided for every order

5.0/5 overall customer rating for product quality and on-time shipment

Material certification and conformity certificates available on request

We have established long-term partnerships with over 5000 global clients, with zero quality complaints for our diving backplate products.

For small-batch orders (1-100 pieces), lead time is 3-7 working days; mass production lead time is negotiated based on order quantity, with fast production capacity to meet your delivery schedule.

Yes, we offer customized surface coatings such as anodizing and powder coating for enhanced marine corrosion resistance, tailored to your specific diving environment needs.

Absolutely, we produce sample backplates for your performance and assembly testing, with sample costs refundable upon mass production order confirmation.

We use CNC laser cutting and automated bending equipment, with a three-step inspection process (pre-production, in-production, post-production) to ensure 100% compliance with your drawing specifications.