Custom sheet metal fabrication encompasses a diverse range of manufacturing processes tailored to create precise, unique metal components according to specific requirements. This field involves sheet metal processing techniques such as stamping, bending, and welding to shape raw metal sheets into intricate parts. Stamping involves using a die to cut or shape metal, while bending utilizes tools to fold and form metal into desired shapes. Welding joins metal pieces together, ensuring structural integrity and durability. Through meticulous craftsmanship and advanced technology, custom sheet metal fabrication transforms raw materials into tailored solutions for various industries, offering versatility, precision, and quality in every component produced.

| Material: | |

|---|---|

| Size: | |

| Availability: | |

| Quantity: | |

OEM/ODM

Our metal processing stamping bending welding service is a one-stop sheet metal fabrication service for global industrial ToB clients, focusing on the integrated processing of metal components through stamping, precision bending and professional welding. Different from single-process metal fabrication, this service delivers ODM bent welded sheet metal components with excellent structural integrity and durability, tailored for clients requiring integrated metal parts for machinery, new energy and medical equipment industries. We combine advanced forming technology and skilled craftsmanship to turn raw metal sheets into high-precision finished components, with full customization support for size, shape and material. Our one-stop industrial metal fabrication service solves the pain points of multi-process procurement and poor part compatibility for clients, realizing efficient, high-quality and cost-effective metal component manufacturing.

Our engineering team provides round-the-clock drawing review and professional optimization suggestions for stamping bending welding parts, focusing on improving bending forming rate and welding structural stability. Clients receive a detailed quotation within 2 hours for all sheet metal fabrication service requests.

We achieve industry-leading precision in both cold stamping and CNC bending, with a tolerance of ±0.0002in for key dimensions. Our professional welding technology ensures no weld defects and high structural strength of bent welded sheet metal components.

With integrated production lines for stamping, bending and welding, we eliminate the time cost of multi-process transfer, reducing the production cycle of metal processing stamping bending welding by up to 50% compared to separate processing.

We provide a full lifecycle service from material selection, integrated processing to surface treatment, quality inspection and global shipping, supporting clients in simplifying supply chain management and reducing overall procurement costs.

Parameter | Detail |

Core Processing | Precision Stamping, CNC Bending, Industrial Welding |

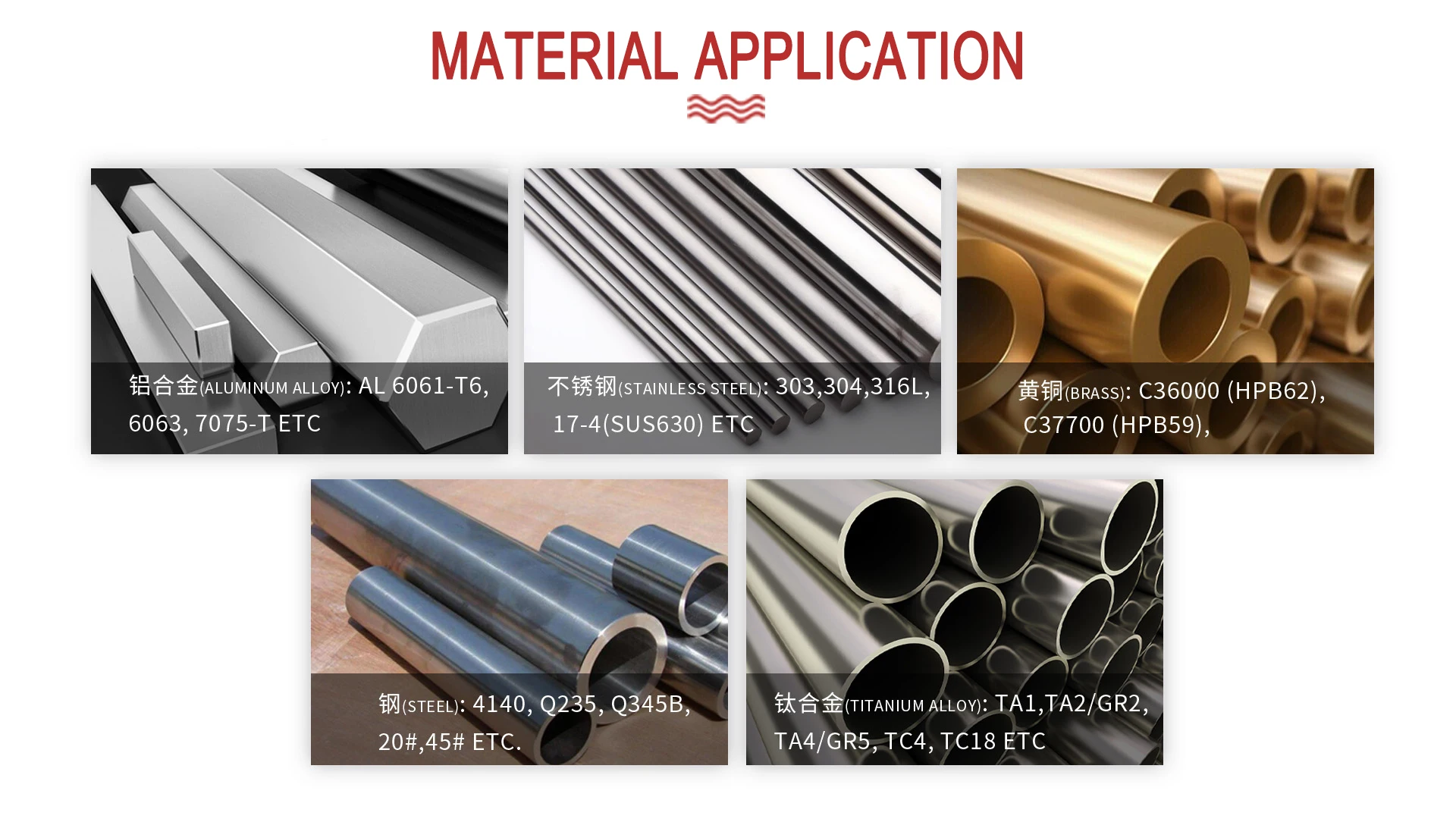

Main Material | Aluminum; SPCC; Steel (Q235, Q345B, 45#) + stainless steel/brass/titanium alloy optional |

Size | Fully customized based on client’s 2D/3D design drawing |

Tolerance | ±0.0002in (for key forming/welding dimensions) |

MOQ | 1 piece (support small-batch ODM customization) |

Model | OEM/ODM (focus on ODM integrated component development) |

Welding Technology | TIG/MIG welding (customizable based on material and structure) |

After-sales | Technical support for part assembly and performance testing |

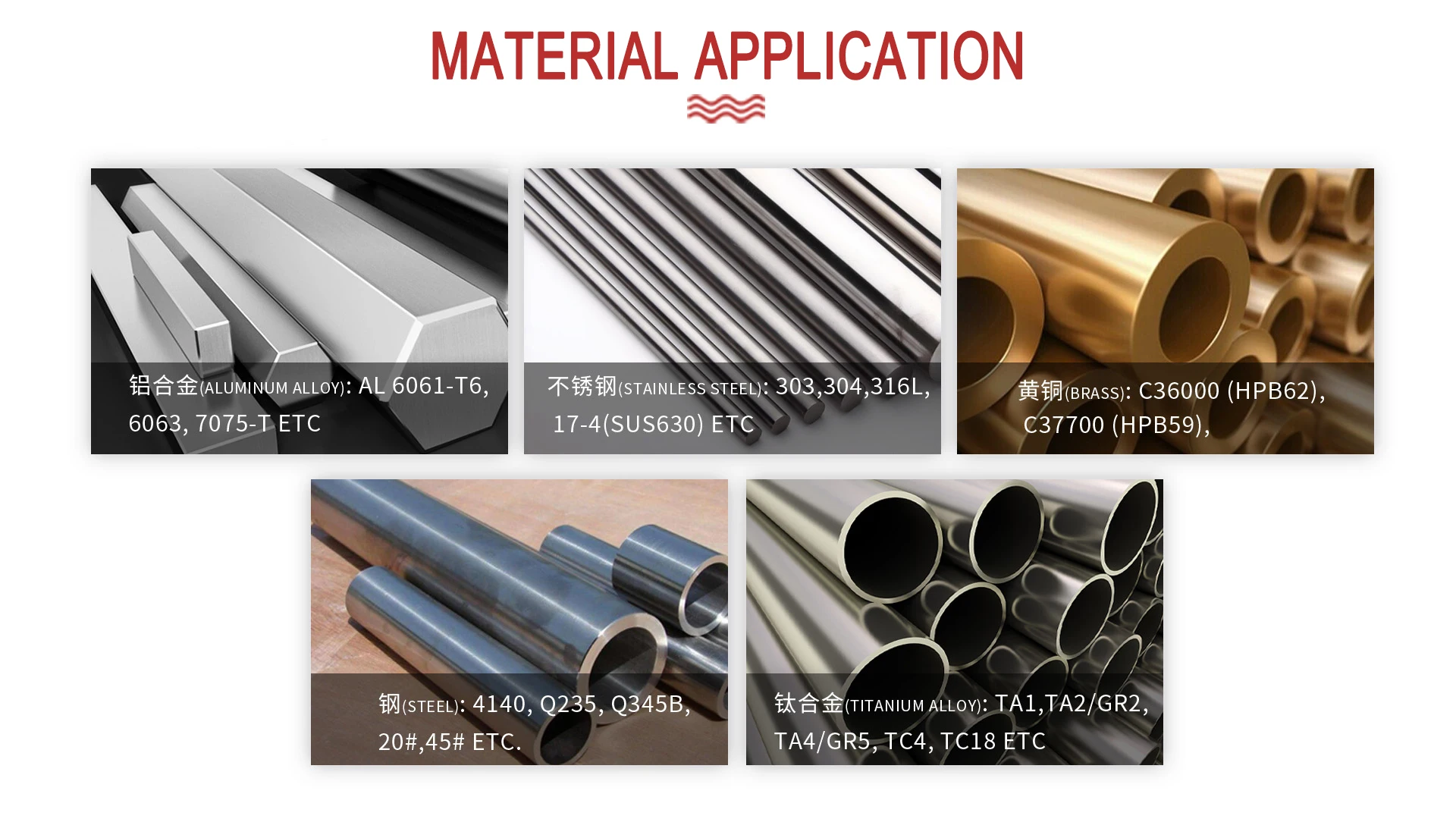

We select industrial materials with excellent formability and weldability for metal processing stamping bending welding, including carbon steel (Q235, Q345B), aluminum alloy (6061-T6, 6063), stainless steel (304, 316L), brass (C36000, C37700) and titanium alloy (TA2, TC4). All materials are tested for formability and weldability to ensure processing performance and final product quality.

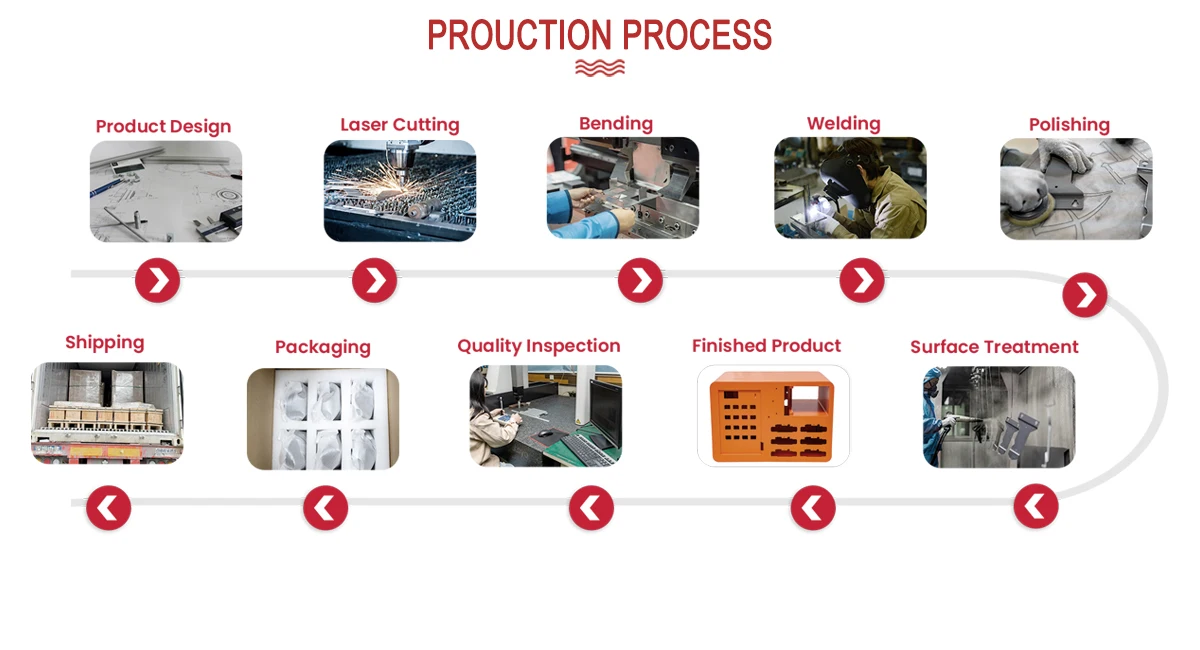

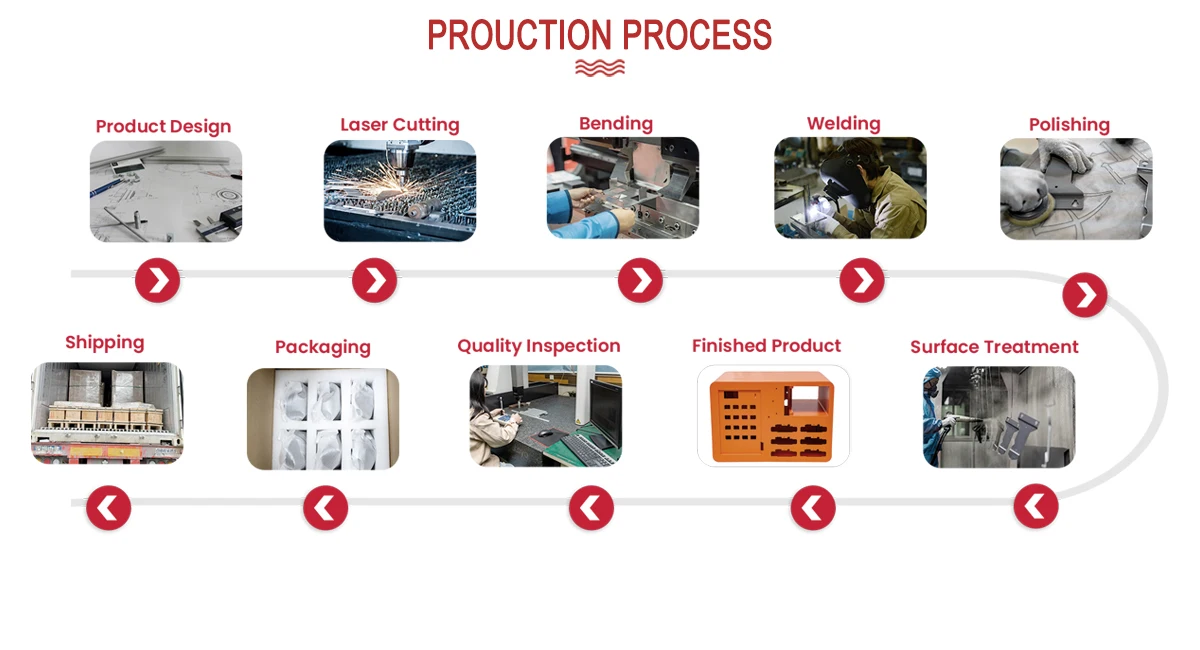

Product Design: CAD/CAM-based optimization of stamping, bending and welding paths for structural efficiency;

Laser Cutting: Pre-cutting of metal sheets to the required size for subsequent forming;

Precision Stamping: Cold stamping of metal blanks into basic shapes with customized dies;

CNC Bending: High-precision folding of stamped parts into 3D shapes with CNC bending machines;

Industrial Welding: TIG/MIG welding of bent parts for structural integration with strict weld quality control;

Polishing & Surface Treatment: Deburring, anti-rust and custom surface processing;

Quality Inspection: Comprehensive testing of dimensions, structural strength and weld performance;

Packaging & Shipping: Custom anti-shock packaging for global delivery with logistics tracking.

Our metal processing stamping bending welding service is widely applied in industrial sectors requiring integrated metal components:

Machinery Industry: Custom bent welded metal parts for industrial machinery frames and transmission systems;

New Energy Industry: Integrated metal components for wind power, solar and energy storage equipment;

Medical Equipment Industry: High-precision stamping bending welding parts for medical devices and diagnostic equipment;

Rail Transit Industry: Structural metal components for rail vehicle interior and mechanical systems.

With over 16 years of experience in sheet metal fabrication service, we offer professional OEM and ODM services for stamping bending welding parts. For OEM clients, we strictly follow the provided drawings to complete integrated processing with 1:1 precision, ensuring perfect compatibility with existing assembly systems. For ODM clients, our R&D team combines industrial application scenarios to provide one-stop design and development services, optimizing stamping, bending and welding processes to improve part structural strength and reduce production costs. We support flexible customization from 1 piece to mass production, with personalized production scheduling for different client demands.

ISO-certified integrated production lines for metal processing stamping bending welding with 16 years of industrial experience;

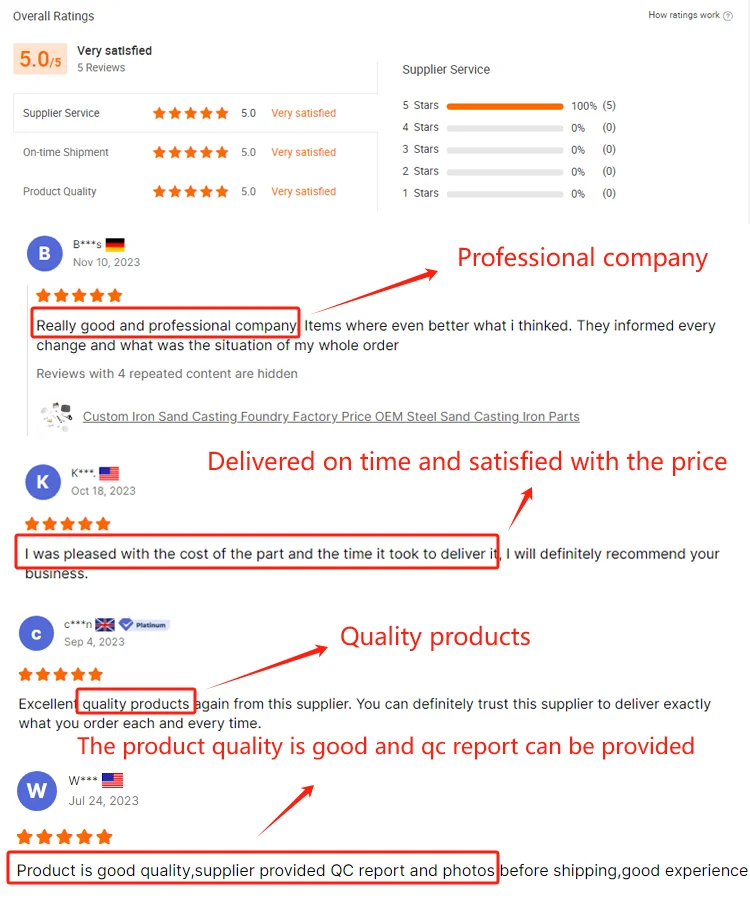

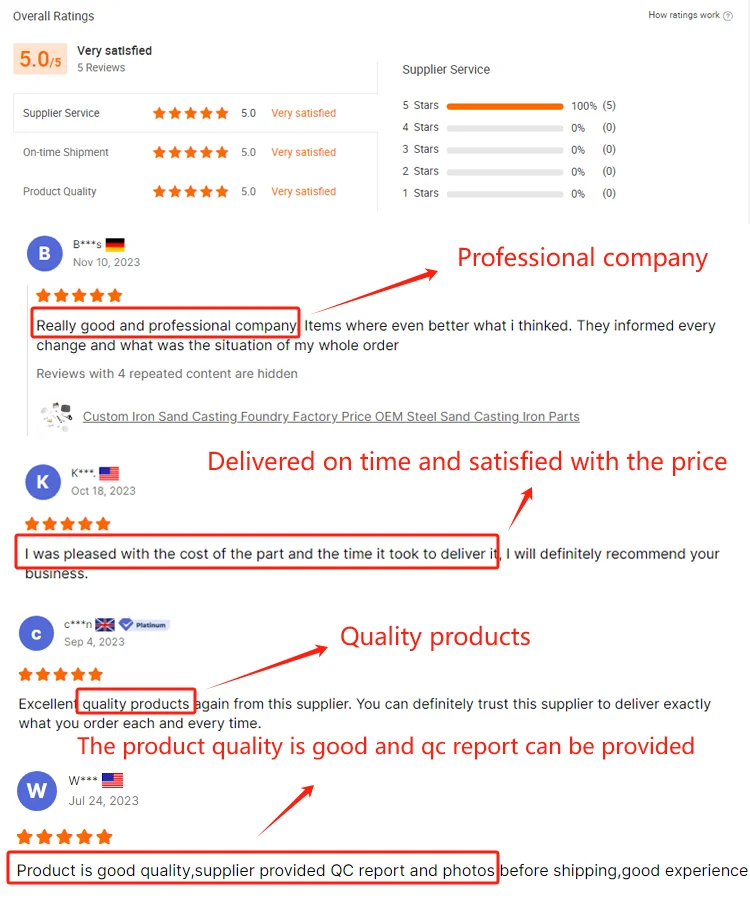

5.0/5 full-score global client evaluation for on-time shipment and product quality, with over 5000 long-term cooperative partners;

Multi-dimensional quality inspection: weld flaw detection, structural strength testing, dimensional precision measurement and material certification;

Pre-shipment QC report, weld inspection photos and product assembly test data provided to clients for full confirmation.

Yes, our engineering team will provide professional optimization suggestions based on material formability, welding process and industrial application scenarios to improve part performance and reduce manufacturing costs.

We adopt advanced TIG/MIG welding technology with 100% weld flaw detection, and conduct structural strength testing for each batch of parts to ensure no weld cracks or deformation.

We support flexible customization with MOQ=1 piece, suitable for both small-batch prototype development and large-scale mass production of stamping bending welding parts.

Our metal processing stamping bending welding service is a one-stop sheet metal fabrication service for global industrial ToB clients, focusing on the integrated processing of metal components through stamping, precision bending and professional welding. Different from single-process metal fabrication, this service delivers ODM bent welded sheet metal components with excellent structural integrity and durability, tailored for clients requiring integrated metal parts for machinery, new energy and medical equipment industries. We combine advanced forming technology and skilled craftsmanship to turn raw metal sheets into high-precision finished components, with full customization support for size, shape and material. Our one-stop industrial metal fabrication service solves the pain points of multi-process procurement and poor part compatibility for clients, realizing efficient, high-quality and cost-effective metal component manufacturing.

Our engineering team provides round-the-clock drawing review and professional optimization suggestions for stamping bending welding parts, focusing on improving bending forming rate and welding structural stability. Clients receive a detailed quotation within 2 hours for all sheet metal fabrication service requests.

We achieve industry-leading precision in both cold stamping and CNC bending, with a tolerance of ±0.0002in for key dimensions. Our professional welding technology ensures no weld defects and high structural strength of bent welded sheet metal components.

With integrated production lines for stamping, bending and welding, we eliminate the time cost of multi-process transfer, reducing the production cycle of metal processing stamping bending welding by up to 50% compared to separate processing.

We provide a full lifecycle service from material selection, integrated processing to surface treatment, quality inspection and global shipping, supporting clients in simplifying supply chain management and reducing overall procurement costs.

Parameter | Detail |

Core Processing | Precision Stamping, CNC Bending, Industrial Welding |

Main Material | Aluminum; SPCC; Steel (Q235, Q345B, 45#) + stainless steel/brass/titanium alloy optional |

Size | Fully customized based on client’s 2D/3D design drawing |

Tolerance | ±0.0002in (for key forming/welding dimensions) |

MOQ | 1 piece (support small-batch ODM customization) |

Model | OEM/ODM (focus on ODM integrated component development) |

Welding Technology | TIG/MIG welding (customizable based on material and structure) |

After-sales | Technical support for part assembly and performance testing |

We select industrial materials with excellent formability and weldability for metal processing stamping bending welding, including carbon steel (Q235, Q345B), aluminum alloy (6061-T6, 6063), stainless steel (304, 316L), brass (C36000, C37700) and titanium alloy (TA2, TC4). All materials are tested for formability and weldability to ensure processing performance and final product quality.

Product Design: CAD/CAM-based optimization of stamping, bending and welding paths for structural efficiency;

Laser Cutting: Pre-cutting of metal sheets to the required size for subsequent forming;

Precision Stamping: Cold stamping of metal blanks into basic shapes with customized dies;

CNC Bending: High-precision folding of stamped parts into 3D shapes with CNC bending machines;

Industrial Welding: TIG/MIG welding of bent parts for structural integration with strict weld quality control;

Polishing & Surface Treatment: Deburring, anti-rust and custom surface processing;

Quality Inspection: Comprehensive testing of dimensions, structural strength and weld performance;

Packaging & Shipping: Custom anti-shock packaging for global delivery with logistics tracking.

Our metal processing stamping bending welding service is widely applied in industrial sectors requiring integrated metal components:

Machinery Industry: Custom bent welded metal parts for industrial machinery frames and transmission systems;

New Energy Industry: Integrated metal components for wind power, solar and energy storage equipment;

Medical Equipment Industry: High-precision stamping bending welding parts for medical devices and diagnostic equipment;

Rail Transit Industry: Structural metal components for rail vehicle interior and mechanical systems.

With over 16 years of experience in sheet metal fabrication service, we offer professional OEM and ODM services for stamping bending welding parts. For OEM clients, we strictly follow the provided drawings to complete integrated processing with 1:1 precision, ensuring perfect compatibility with existing assembly systems. For ODM clients, our R&D team combines industrial application scenarios to provide one-stop design and development services, optimizing stamping, bending and welding processes to improve part structural strength and reduce production costs. We support flexible customization from 1 piece to mass production, with personalized production scheduling for different client demands.

ISO-certified integrated production lines for metal processing stamping bending welding with 16 years of industrial experience;

5.0/5 full-score global client evaluation for on-time shipment and product quality, with over 5000 long-term cooperative partners;

Multi-dimensional quality inspection: weld flaw detection, structural strength testing, dimensional precision measurement and material certification;

Pre-shipment QC report, weld inspection photos and product assembly test data provided to clients for full confirmation.

Yes, our engineering team will provide professional optimization suggestions based on material formability, welding process and industrial application scenarios to improve part performance and reduce manufacturing costs.

We adopt advanced TIG/MIG welding technology with 100% weld flaw detection, and conduct structural strength testing for each batch of parts to ensure no weld cracks or deformation.

We support flexible customization with MOQ=1 piece, suitable for both small-batch prototype development and large-scale mass production of stamping bending welding parts.