Custom metal stamping parts are essential components in various industries, offering precise and reliable solutions for a multitude of applications. Metal stamping involves the process of transforming flat sheets of metal into desired shapes and sizes using a stamping press and tooling. These parts are crafted to meet specific requirements, offering flexibility in design, material selection, and functionality. From automotive and aerospace to electronics and consumer goods, custom metal stamping parts play a pivotal role in manufacturing processes, providing durability, efficiency, and cost-effectiveness. With advancements in technology and manufacturing techniques, these parts continue to evolve, meeting the ever-changing demands of modern industries.

| Material: | |

|---|---|

| Size: | |

| Availability: | |

| Quantity: | |

OEM/ODM

Our custom sheet metal stamping parts are designed for industrial customers who demand high precision, consistent performance and cost-effective mass production. We process a full range of metal materials, with advanced stamping, laser cutting, bending, welding and surface treatment lines. Every part is manufactured strictly to customer drawings, ensuring perfect fit and long service life for automotive, electronics, machinery, medical and other critical applications.

±0.0002in High Precision Stamping

Ultra-tight tolerance control meets the strict requirements of aerospace, medical and high-end electronic components, reducing assembly failure and rework costs.

1-Piece Minimum Order Quantity

Support prototype, small-batch trial and mass production, fully matching your R&D and large-scale manufacturing needs.

2-Hour Fast Quotation

7×24 professional engineering team reviews your 2D/3D drawings and provides accurate quotes within 2 hours, speeding up your project progress.

One-Stop Sheet Metal Fabrication

Integrated design, processing, surface treatment and assembly services eliminate multi-supplier coordination and lower your total procurement cost.

ISO-Certified Quality System

Full inspection from raw material to finished product, with complete QC reports and material certificates for every shipment.

Parameter | Details |

Product Name | Custom Sheet Metal Stamping Parts, Sheet Metal Fabrication Products |

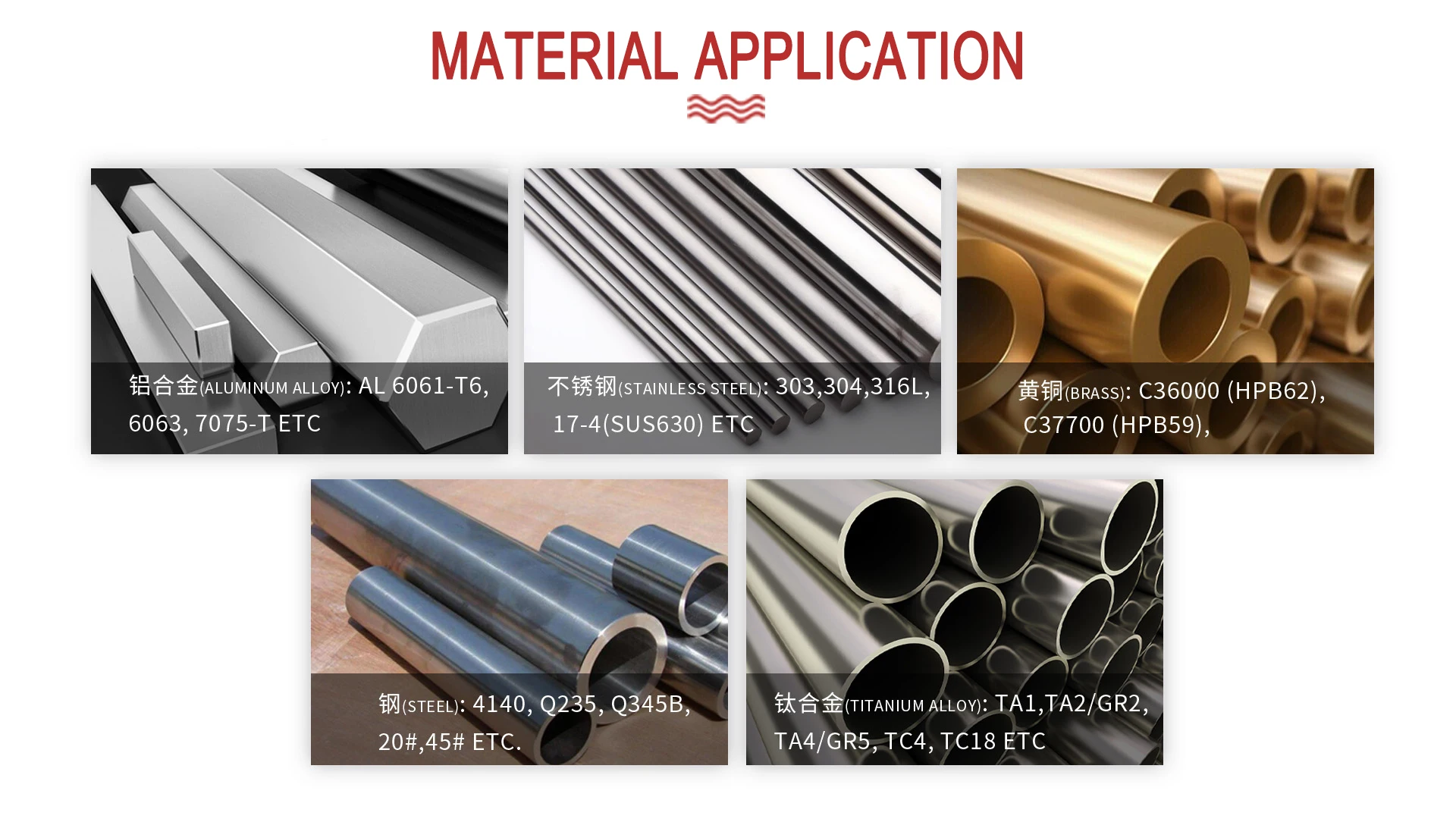

Available Materials | Stainless Steel (304, 316L, 430); Aluminum Alloy (5052, 6061-T6, 7075); Cold Rolled Steel, Galvanized Steel, Brass, Copper |

Manufacturing Process | Stamping, Laser Cutting, Bending, Welding, Tapping, Riveting, Final Assembly |

Precision Tolerance | ±0.0002in (0.05mm) for high-precision components |

Surface Treatment | Brushing, Polishing, Powder Coating, Anodizing, Electroplating, Sandblasting |

Custom Dimensions | Fully customized as per 2D/3D drawings (CAD, DXF, STEP, SolidWorks) |

Minimum Order Quantity | 1 Piece (prototypes, small batches & mass production all supported) |

Quotation Response | 2 Hours (drawing evaluation + official quote) |

Standard Lead Time | 7–15 working days (urgent orders can be expedited) |

Quality Certificates | ISO 9001, material certification, full QC inspection report |

Main Applications | Automotive, Electronics, Medical Equipment, Industrial Machinery, Home Appliances, Furniture |

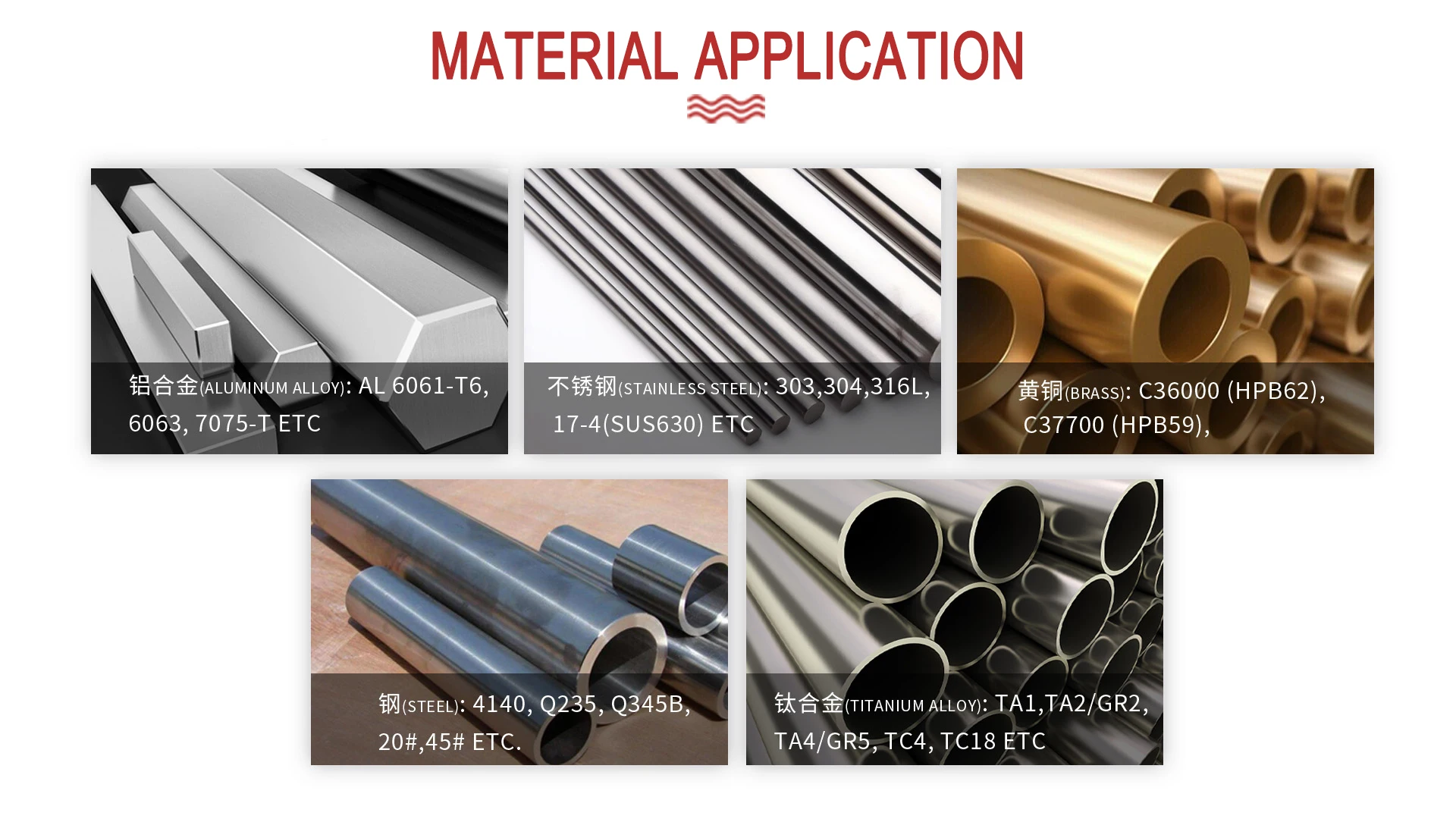

We use premium certified metals to ensure stability and durability of your stainless steel sheet metal fabrication parts:

Stainless Steel: 304, 316L, 430

Aluminum Alloy: 5052, 6061-T6, 7075

Cold Rolled Steel, Galvanized Steel, Brass, Copper

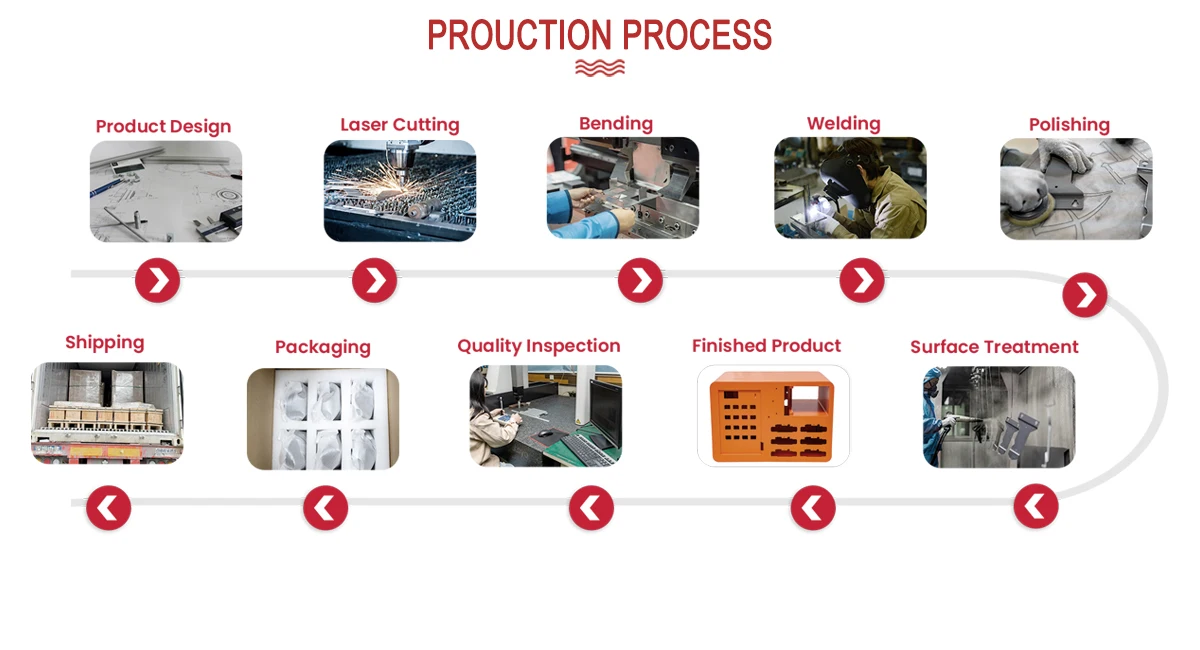

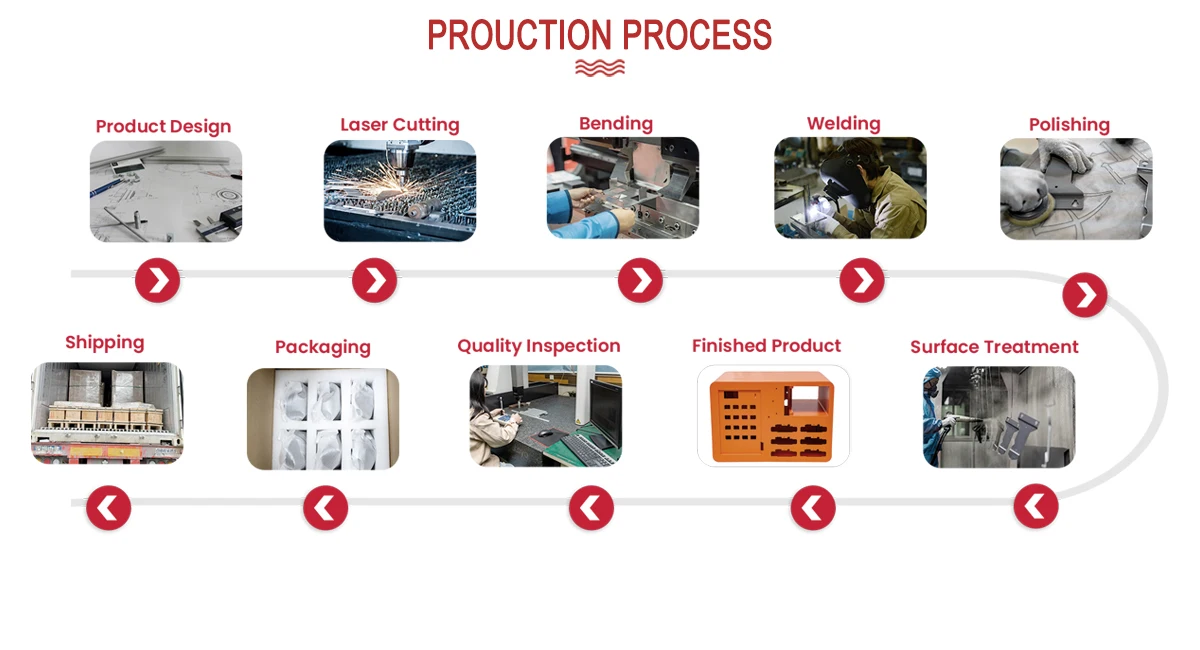

Our standard production flow:

Drawing confirmation & engineering optimization

Raw material inspection & cutting

Precision stamping / laser cutting / bending

Welding, tapping and riveting

Surface treatment (brushing, polishing, powder coating, anodizing)

100% dimensional & performance inspection

Packaging & on-time delivery

Our custom sheet metal stamping parts serve a wide range of industrial sectors:

Automotive: chassis brackets, housing parts, structural components

Electronics: enclosures, heat sinks, connector parts

Medical Equipment: corrosion-resistant precision components

Industrial Machinery: support frames, operation panels

Home Appliances & Furniture: metal fittings, decorative parts

We provide full-cycle customization for your sheet metal work projects:

Accept CAD, STEP, SolidWorks drawings

Free design optimization and manufacturability suggestions

Customized surface treatment and logo processing

Flexible packaging and shipping solutions

Dedicated project manager for real-time production updates

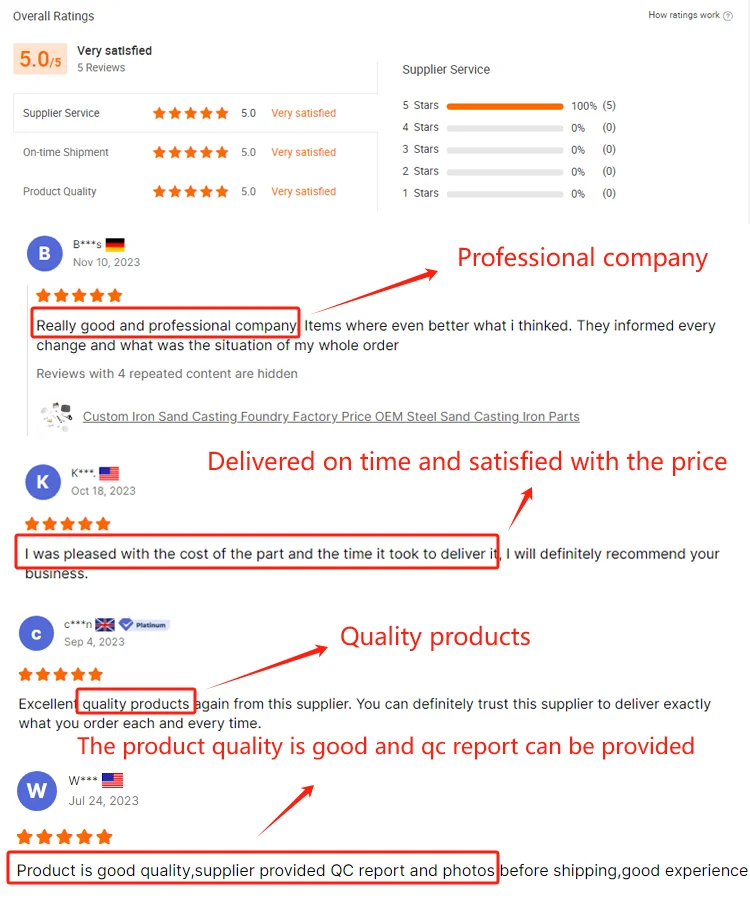

16+ years of sheet metal fabrication experience

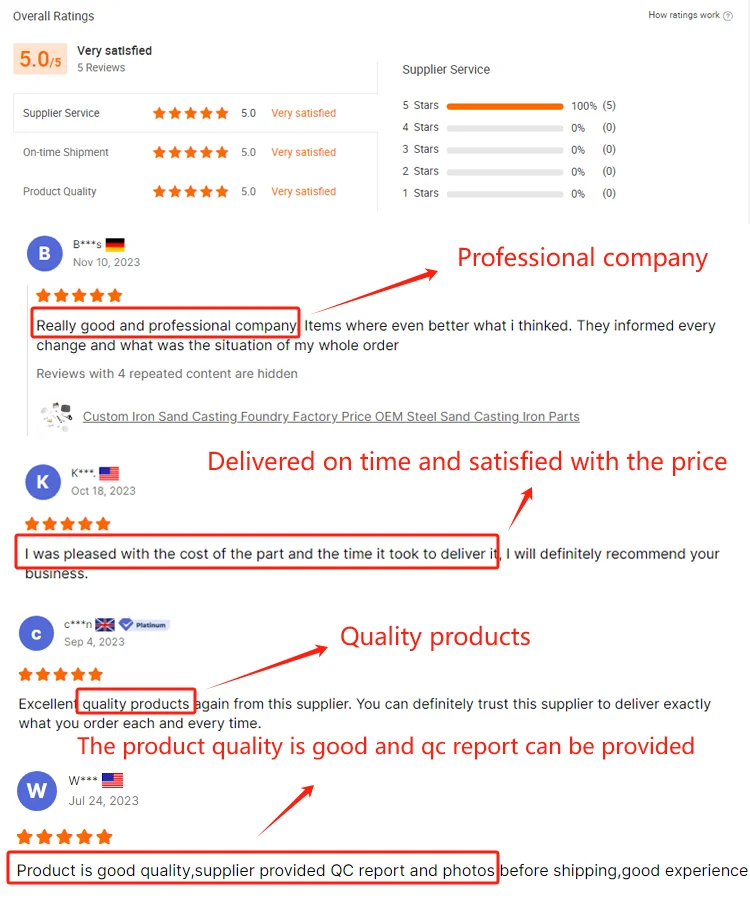

ISO 9001 quality management system

Advanced 3D measuring and testing equipment

Full inspection reports and material certifications

100% on-time delivery rate

We accept DWG, DXF, STEP, SolidWorks and PDF drawings for fast and accurate quoting.

Yes, we offer prototype samples to confirm dimensions, surface and assembly performance before formal orders.

Standard lead time is 7–15 days, depending on part complexity and order volume; urgent orders can be expedited.

Send us your 2D/3D drawing now to get a free 2-hour quotation for your custom sheet metal stamping parts and stainless steel sheet metal fabrication project. We provide reliable one-stop OEM service to support your global business growth.

Our custom sheet metal stamping parts are designed for industrial customers who demand high precision, consistent performance and cost-effective mass production. We process a full range of metal materials, with advanced stamping, laser cutting, bending, welding and surface treatment lines. Every part is manufactured strictly to customer drawings, ensuring perfect fit and long service life for automotive, electronics, machinery, medical and other critical applications.

±0.0002in High Precision Stamping

Ultra-tight tolerance control meets the strict requirements of aerospace, medical and high-end electronic components, reducing assembly failure and rework costs.

1-Piece Minimum Order Quantity

Support prototype, small-batch trial and mass production, fully matching your R&D and large-scale manufacturing needs.

2-Hour Fast Quotation

7×24 professional engineering team reviews your 2D/3D drawings and provides accurate quotes within 2 hours, speeding up your project progress.

One-Stop Sheet Metal Fabrication

Integrated design, processing, surface treatment and assembly services eliminate multi-supplier coordination and lower your total procurement cost.

ISO-Certified Quality System

Full inspection from raw material to finished product, with complete QC reports and material certificates for every shipment.

Parameter | Details |

Product Name | Custom Sheet Metal Stamping Parts, Sheet Metal Fabrication Products |

Available Materials | Stainless Steel (304, 316L, 430); Aluminum Alloy (5052, 6061-T6, 7075); Cold Rolled Steel, Galvanized Steel, Brass, Copper |

Manufacturing Process | Stamping, Laser Cutting, Bending, Welding, Tapping, Riveting, Final Assembly |

Precision Tolerance | ±0.0002in (0.05mm) for high-precision components |

Surface Treatment | Brushing, Polishing, Powder Coating, Anodizing, Electroplating, Sandblasting |

Custom Dimensions | Fully customized as per 2D/3D drawings (CAD, DXF, STEP, SolidWorks) |

Minimum Order Quantity | 1 Piece (prototypes, small batches & mass production all supported) |

Quotation Response | 2 Hours (drawing evaluation + official quote) |

Standard Lead Time | 7–15 working days (urgent orders can be expedited) |

Quality Certificates | ISO 9001, material certification, full QC inspection report |

Main Applications | Automotive, Electronics, Medical Equipment, Industrial Machinery, Home Appliances, Furniture |

We use premium certified metals to ensure stability and durability of your stainless steel sheet metal fabrication parts:

Stainless Steel: 304, 316L, 430

Aluminum Alloy: 5052, 6061-T6, 7075

Cold Rolled Steel, Galvanized Steel, Brass, Copper

Our standard production flow:

Drawing confirmation & engineering optimization

Raw material inspection & cutting

Precision stamping / laser cutting / bending

Welding, tapping and riveting

Surface treatment (brushing, polishing, powder coating, anodizing)

100% dimensional & performance inspection

Packaging & on-time delivery

Our custom sheet metal stamping parts serve a wide range of industrial sectors:

Automotive: chassis brackets, housing parts, structural components

Electronics: enclosures, heat sinks, connector parts

Medical Equipment: corrosion-resistant precision components

Industrial Machinery: support frames, operation panels

Home Appliances & Furniture: metal fittings, decorative parts

We provide full-cycle customization for your sheet metal work projects:

Accept CAD, STEP, SolidWorks drawings

Free design optimization and manufacturability suggestions

Customized surface treatment and logo processing

Flexible packaging and shipping solutions

Dedicated project manager for real-time production updates

16+ years of sheet metal fabrication experience

ISO 9001 quality management system

Advanced 3D measuring and testing equipment

Full inspection reports and material certifications

100% on-time delivery rate

We accept DWG, DXF, STEP, SolidWorks and PDF drawings for fast and accurate quoting.

Yes, we offer prototype samples to confirm dimensions, surface and assembly performance before formal orders.

Standard lead time is 7–15 days, depending on part complexity and order volume; urgent orders can be expedited.

Send us your 2D/3D drawing now to get a free 2-hour quotation for your custom sheet metal stamping parts and stainless steel sheet metal fabrication project. We provide reliable one-stop OEM service to support your global business growth.