High Precision Stainless Steel 304/316L Sheet Metal Machining Stamping Parts with Punching Metal Stamping Parts epitomize the pinnacle of precision engineering and metal fabrication. Crafted from top-grade stainless steel 304 or 316L, renowned for its exceptional durability and corrosion resistance, these parts are engineered to meet the most exacting standards of quality and performance.

| Material: | |

|---|---|

| Size: | |

| Availability: | |

| Quantity: | |

OEM/ODM

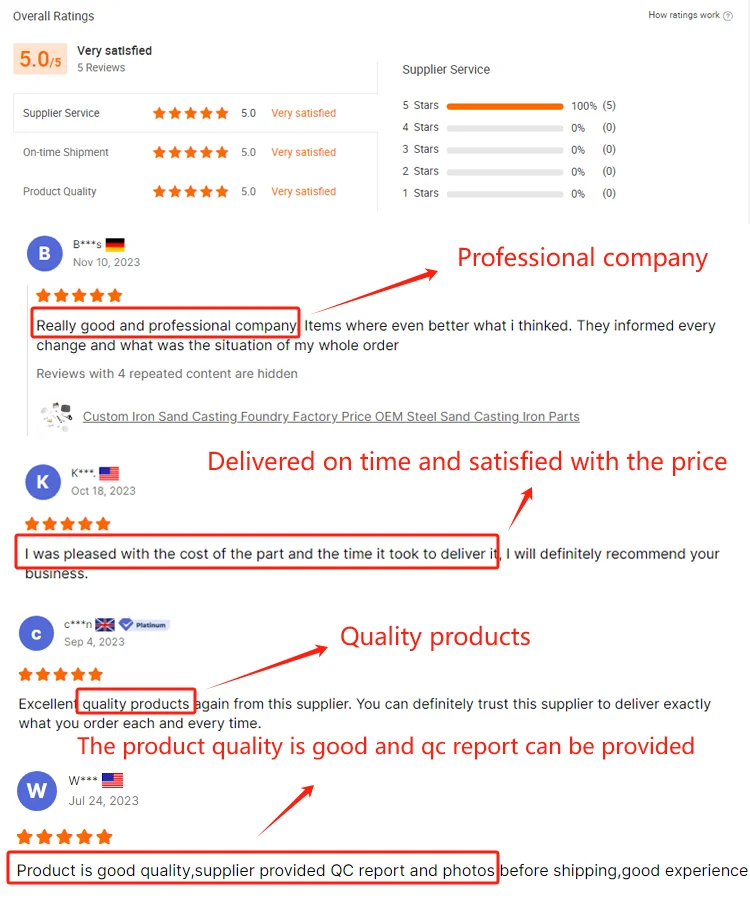

304 stainless steel stamping parts and 316L stainless steel sheet metal machining parts are the core products of Longwang Hardware for high-end industrial applications, and our high precision stainless steel stamping parts are crafted from top-grade 303/304/316L stainless steel with exceptional corrosion resistance, durability and mechanical strength. Combining advanced stainless steel sheet metal machining and precision punching technology, we realize seamless integration of complex geometries and micro-dimensional control, making the products suitable for long-term operation in harsh industrial environments such as high humidity, corrosion and high temperature. As a professional ToB supplier of stainless steel metal components, we focus on providing aerospace, automotive and marine engineering clients with high-consistency, high-reliability 316L stainless steel machining parts, with 16 years of customized production experience and a 5.0/5 global client satisfaction rating.

Our 303 stainless steel stamping parts and 304/316L machining parts are made of food/industrial grade stainless steel, with 316L grade featuring seawater corrosion resistance, suitable for marine and chemical industry applications.

We combine CNC machining and high-precision stamping, realizing one-time forming of complex stainless steel components, avoiding secondary processing errors and improving product dimensional accuracy.

A full range of stainless steel-specific surface treatment processes (passivation, sandblasting, electropolishing) are available to enhance corrosion resistance and surface finish of aerospace grade 316L stainless steel parts.

We provide door-to-door shipping service for global clients, with professional packaging to prevent stainless steel parts from oxidation and collision damage during transportation.

Item | Specification |

Core Material | 303/304/316L Stainless Steel (17-4 SUS630 optional) |

Size | Customized by 2D/3D drawing (support micro-size processing) |

MOQ | 1 PCS (small batch high-precision trial production) |

Tolerance | ±0.0002in (for high-precision machining stamping parts) |

Model | OEM/ODM (custom structural design supported) |

Surface Treatment | Passivation, electropolishing, sandblasting (stainless steel-specific) |

Quality Report | Material certification, QC report, salt spray test report |

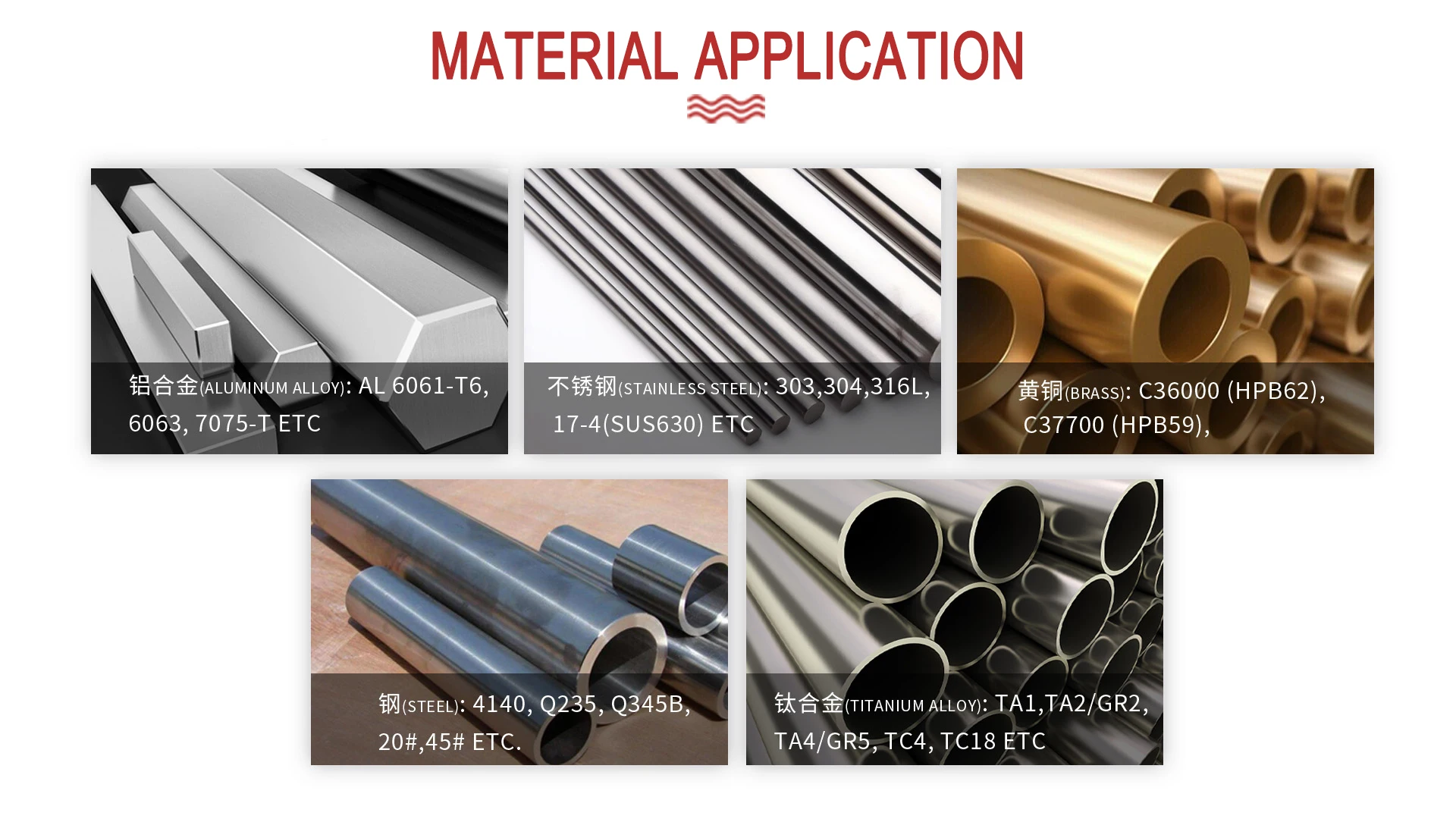

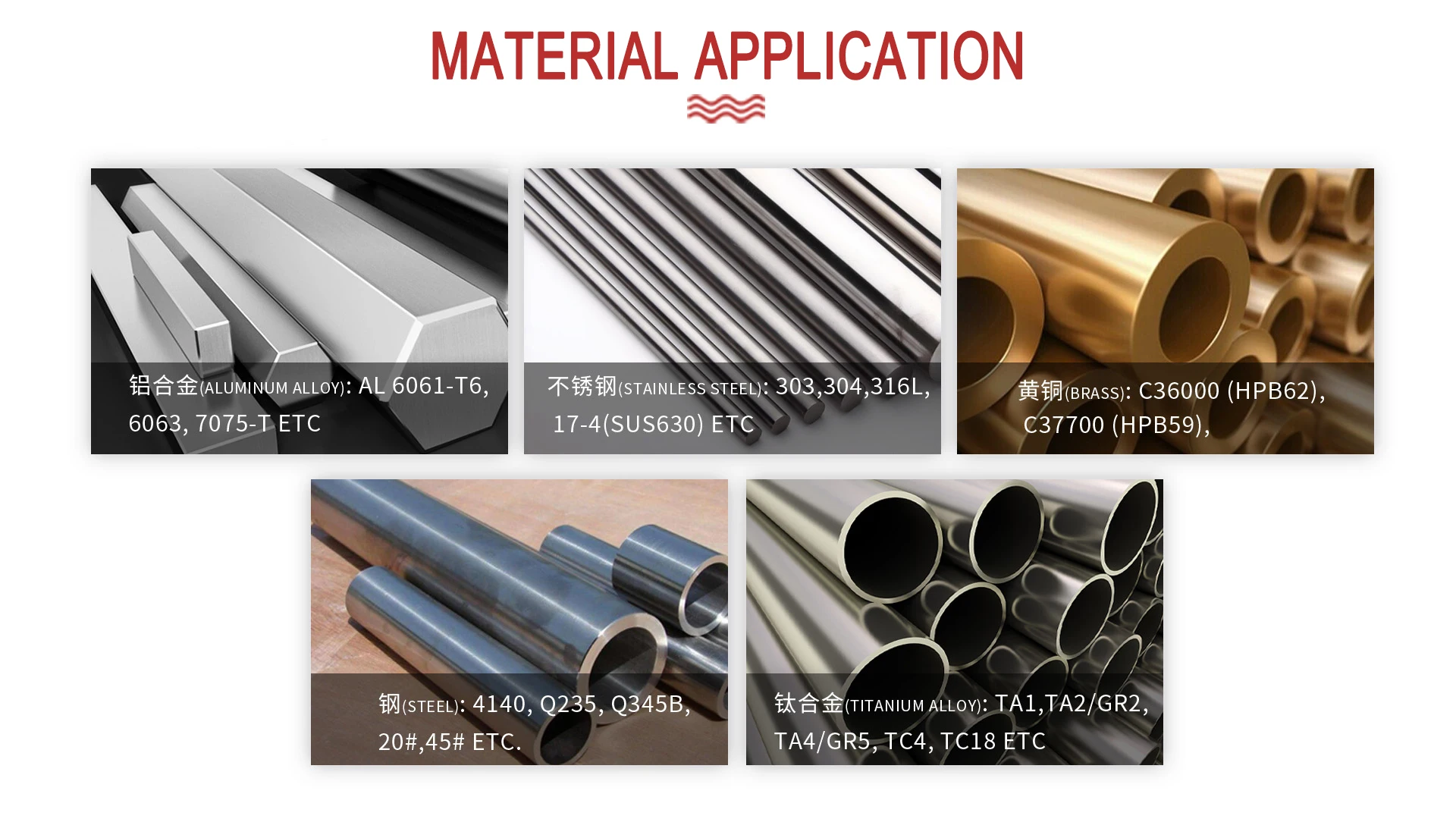

We select top-grade stainless steel raw materials with stable chemical composition, matching different high-end industrial application scenarios:

303 Stainless Steel: Good machinability, suitable for precision stainless steel stamping parts with complex threads and slots;

304 Stainless Steel: Balanced corrosion resistance and cost, ideal for general high-end industrial equipment components;

316L Stainless Steel: Molybdenum-added for seawater/chemical corrosion resistance, for marine corrosion-resistant stainless steel stamping parts and aerospace components;

All materials are accompanied by official material certification to ensure product traceability.

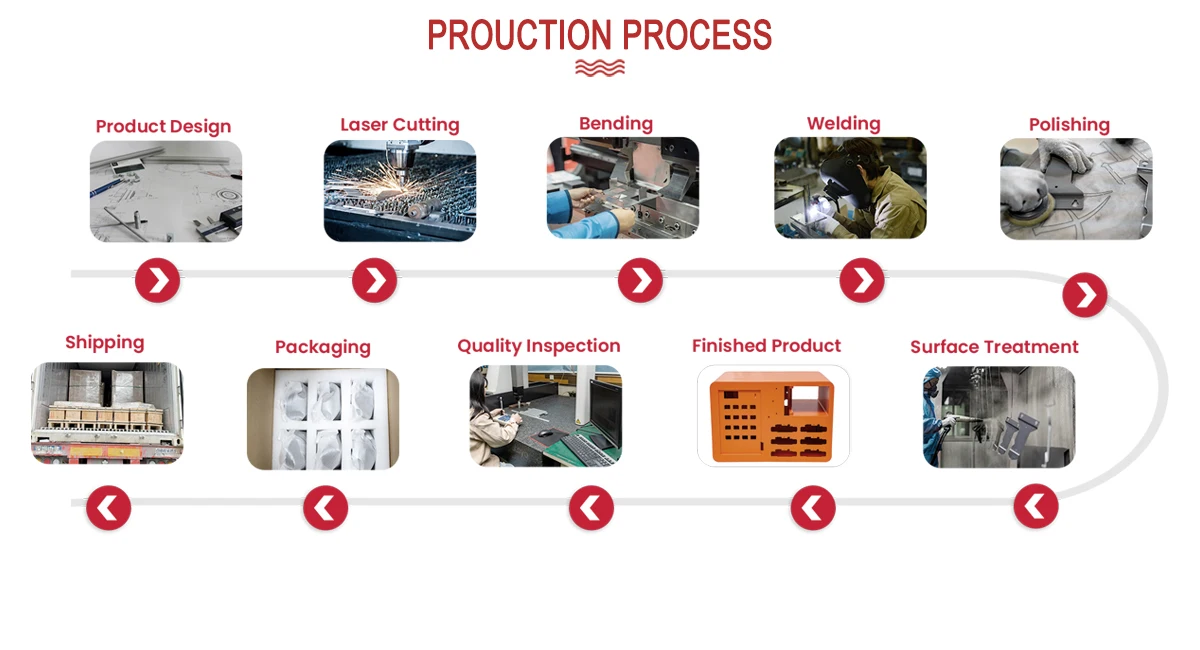

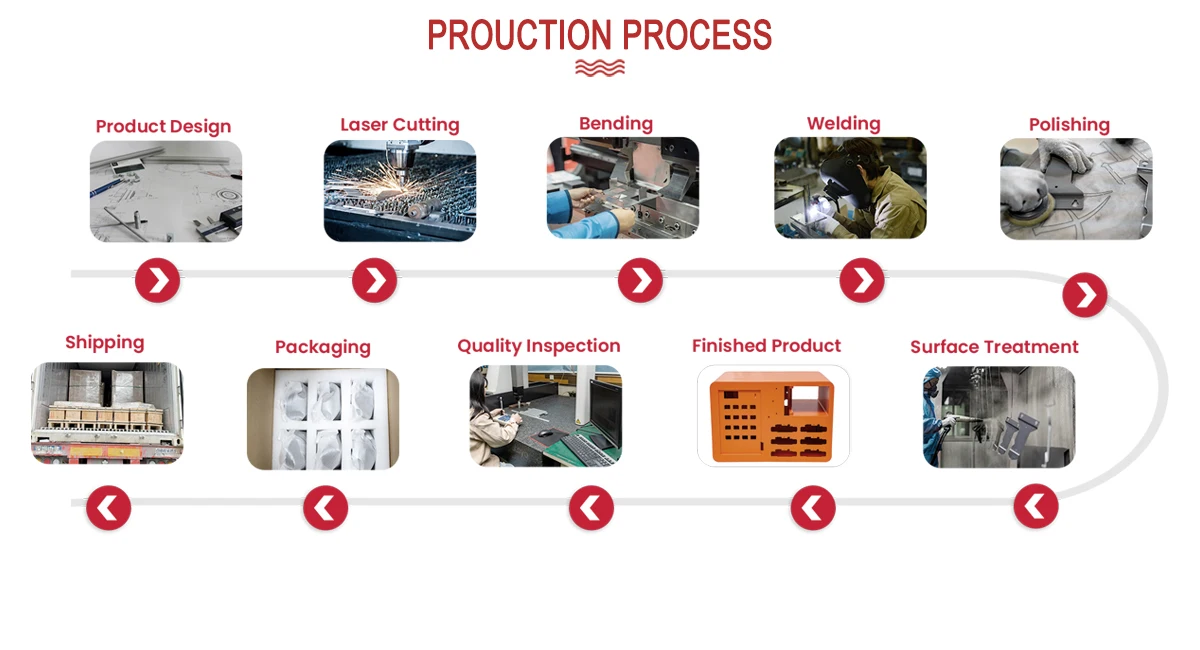

Aiming at the high hardness and toughness of stainless steel, we adopt a specialized processing process: Product Design & Material Selection → High-Precision Laser Cutting → CNC Bending → Argon Arc Welding (stainless steel-specific) → Precision Machining → Stainless Steel Surface Treatment → Salt Spray Test → Quality Inspection → Anti-Oxidation Packaging → Shipping. Each process is optimized for stainless steel to avoid material deformation and oxidation.

Our high precision 304/316L stainless steel sheet metal machining stamping parts are widely used in high-end industrial sectors with strict material and precision requirements:

Aerospace Industry: Aerospace equipment structural parts, satellite component brackets, aircraft hydraulic system parts;

Marine Engineering: Ship deck hardware, marine instrument housings, offshore platform corrosion-resistant components;

High-End Automotive Industry: New energy vehicle battery components, engine precision parts, exhaust system components;

Medical & Chemical Industry: Medical equipment precision parts, chemical reactor components, food processing equipment parts;

All products pass strict environmental adaptability tests and meet the industry standards of the corresponding sectors.

We provide professional 304/316L stainless steel stamping parts OEM/ODM service for high-end industrial clients, with customized solutions covering the entire production chain:

Professional material selection guidance: According to the client’s application environment (corrosion, temperature, load), recommend the most suitable stainless steel grade (303/304/316L);

Accept high-precision custom drawings: Support micro-dimensional and complex structural design, and provide free process optimization to ensure machining feasibility;

Custom performance testing: According to client needs, conduct salt spray corrosion test, mechanical strength test and dimensional accuracy test, and provide detailed test reports;

Flexible production: Support small-batch high-precision trial production and large-scale mass production, with real-time production progress feedback.

Stainless Steel Specialized Inspection: Equipped with precision testing equipment such as coordinate measuring machine and salt spray testing machine, 100% inspect the dimensional accuracy and corrosion resistance of products;

Complete Certification System: Provide material certification, ISO conformity certificate, salt spray test report and advanced inspection report for all stainless steel products;

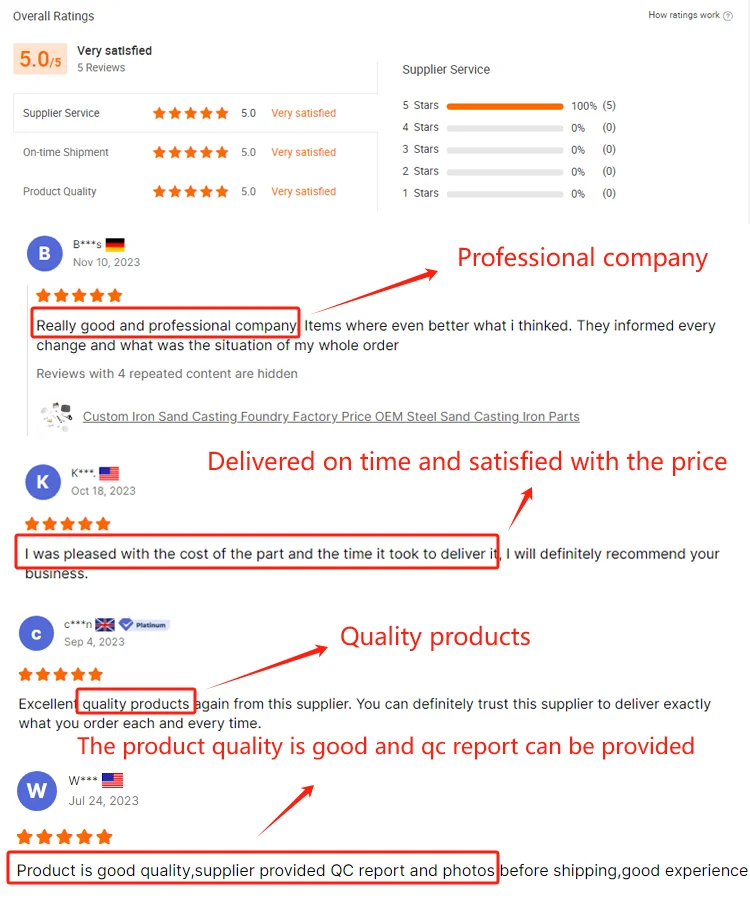

Global Client Recognition: 5000+ global cooperative partners, 5.0/5 ratings in product quality, on-time shipment and after-sales service, with positive feedback on stainless steel part durability;

Anti-Oxidation Guarantee: Adopt vacuum anti-oxidation packaging for stainless steel parts, and provide long-term storage and maintenance suggestions to avoid material oxidation.

We mainly provide 303, 304, 316L stainless steel, and optional 17-4 (SUS630) grade for high-strength requirements, and can recommend the most suitable grade according to your application environment.

Yes, we can conduct salt spray corrosion tests of different durations (48/96/120 hours) according to your needs, and provide a detailed salt spray test report to verify the corrosion resistance of the product.

We use professional vacuum anti-oxidation packaging for all stainless steel products, and attach anti-rust oil and desiccant inside the package. We also provide detailed storage and maintenance suggestions to ensure the product surface is not oxidized.

304 stainless steel stamping parts and 316L stainless steel sheet metal machining parts are the core products of Longwang Hardware for high-end industrial applications, and our high precision stainless steel stamping parts are crafted from top-grade 303/304/316L stainless steel with exceptional corrosion resistance, durability and mechanical strength. Combining advanced stainless steel sheet metal machining and precision punching technology, we realize seamless integration of complex geometries and micro-dimensional control, making the products suitable for long-term operation in harsh industrial environments such as high humidity, corrosion and high temperature. As a professional ToB supplier of stainless steel metal components, we focus on providing aerospace, automotive and marine engineering clients with high-consistency, high-reliability 316L stainless steel machining parts, with 16 years of customized production experience and a 5.0/5 global client satisfaction rating.

Our 303 stainless steel stamping parts and 304/316L machining parts are made of food/industrial grade stainless steel, with 316L grade featuring seawater corrosion resistance, suitable for marine and chemical industry applications.

We combine CNC machining and high-precision stamping, realizing one-time forming of complex stainless steel components, avoiding secondary processing errors and improving product dimensional accuracy.

A full range of stainless steel-specific surface treatment processes (passivation, sandblasting, electropolishing) are available to enhance corrosion resistance and surface finish of aerospace grade 316L stainless steel parts.

We provide door-to-door shipping service for global clients, with professional packaging to prevent stainless steel parts from oxidation and collision damage during transportation.

Item | Specification |

Core Material | 303/304/316L Stainless Steel (17-4 SUS630 optional) |

Size | Customized by 2D/3D drawing (support micro-size processing) |

MOQ | 1 PCS (small batch high-precision trial production) |

Tolerance | ±0.0002in (for high-precision machining stamping parts) |

Model | OEM/ODM (custom structural design supported) |

Surface Treatment | Passivation, electropolishing, sandblasting (stainless steel-specific) |

Quality Report | Material certification, QC report, salt spray test report |

We select top-grade stainless steel raw materials with stable chemical composition, matching different high-end industrial application scenarios:

303 Stainless Steel: Good machinability, suitable for precision stainless steel stamping parts with complex threads and slots;

304 Stainless Steel: Balanced corrosion resistance and cost, ideal for general high-end industrial equipment components;

316L Stainless Steel: Molybdenum-added for seawater/chemical corrosion resistance, for marine corrosion-resistant stainless steel stamping parts and aerospace components;

All materials are accompanied by official material certification to ensure product traceability.

Aiming at the high hardness and toughness of stainless steel, we adopt a specialized processing process: Product Design & Material Selection → High-Precision Laser Cutting → CNC Bending → Argon Arc Welding (stainless steel-specific) → Precision Machining → Stainless Steel Surface Treatment → Salt Spray Test → Quality Inspection → Anti-Oxidation Packaging → Shipping. Each process is optimized for stainless steel to avoid material deformation and oxidation.

Our high precision 304/316L stainless steel sheet metal machining stamping parts are widely used in high-end industrial sectors with strict material and precision requirements:

Aerospace Industry: Aerospace equipment structural parts, satellite component brackets, aircraft hydraulic system parts;

Marine Engineering: Ship deck hardware, marine instrument housings, offshore platform corrosion-resistant components;

High-End Automotive Industry: New energy vehicle battery components, engine precision parts, exhaust system components;

Medical & Chemical Industry: Medical equipment precision parts, chemical reactor components, food processing equipment parts;

All products pass strict environmental adaptability tests and meet the industry standards of the corresponding sectors.

We provide professional 304/316L stainless steel stamping parts OEM/ODM service for high-end industrial clients, with customized solutions covering the entire production chain:

Professional material selection guidance: According to the client’s application environment (corrosion, temperature, load), recommend the most suitable stainless steel grade (303/304/316L);

Accept high-precision custom drawings: Support micro-dimensional and complex structural design, and provide free process optimization to ensure machining feasibility;

Custom performance testing: According to client needs, conduct salt spray corrosion test, mechanical strength test and dimensional accuracy test, and provide detailed test reports;

Flexible production: Support small-batch high-precision trial production and large-scale mass production, with real-time production progress feedback.

Stainless Steel Specialized Inspection: Equipped with precision testing equipment such as coordinate measuring machine and salt spray testing machine, 100% inspect the dimensional accuracy and corrosion resistance of products;

Complete Certification System: Provide material certification, ISO conformity certificate, salt spray test report and advanced inspection report for all stainless steel products;

Global Client Recognition: 5000+ global cooperative partners, 5.0/5 ratings in product quality, on-time shipment and after-sales service, with positive feedback on stainless steel part durability;

Anti-Oxidation Guarantee: Adopt vacuum anti-oxidation packaging for stainless steel parts, and provide long-term storage and maintenance suggestions to avoid material oxidation.

We mainly provide 303, 304, 316L stainless steel, and optional 17-4 (SUS630) grade for high-strength requirements, and can recommend the most suitable grade according to your application environment.

Yes, we can conduct salt spray corrosion tests of different durations (48/96/120 hours) according to your needs, and provide a detailed salt spray test report to verify the corrosion resistance of the product.

We use professional vacuum anti-oxidation packaging for all stainless steel products, and attach anti-rust oil and desiccant inside the package. We also provide detailed storage and maintenance suggestions to ensure the product surface is not oxidized.