China Custom Fabrication Stainless Steel Service, your premier destination for precision craftsmanship and top-quality stainless steel solutions. With years of expertise and a commitment to excellence, we specialize in crafting custom stainless steel products tailored to meet your exact specifications. Whether you're in need of intricate components, structural pieces, or artistic designs, our skilled craftsmen utilize state-of-the-art technology and meticulous attention to detail to bring your visions to life. From concept to completion, we pride ourselves on delivering superior results that exceed expectations. Trust China Custom Fabrication Stainless Steel Service for all your fabrication needs, and experience the unmatched quality and reliability that sets us apart.

| Material: | |

|---|---|

| Size: | |

| Availability: | |

| Quantity: | |

OEM/ODM

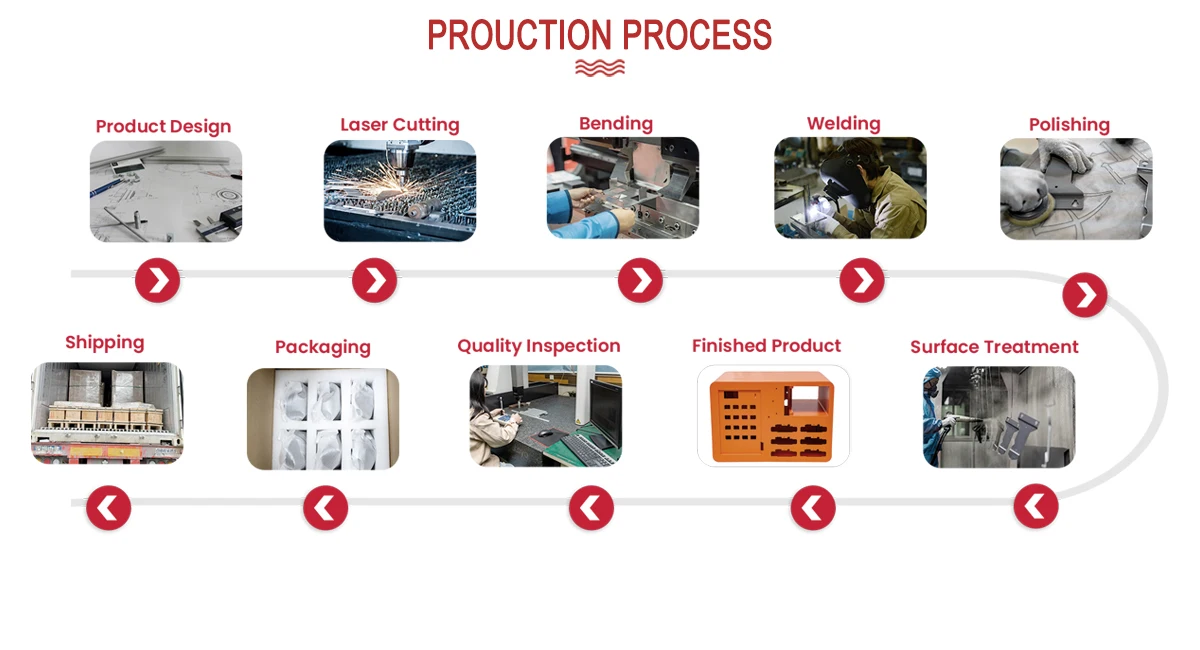

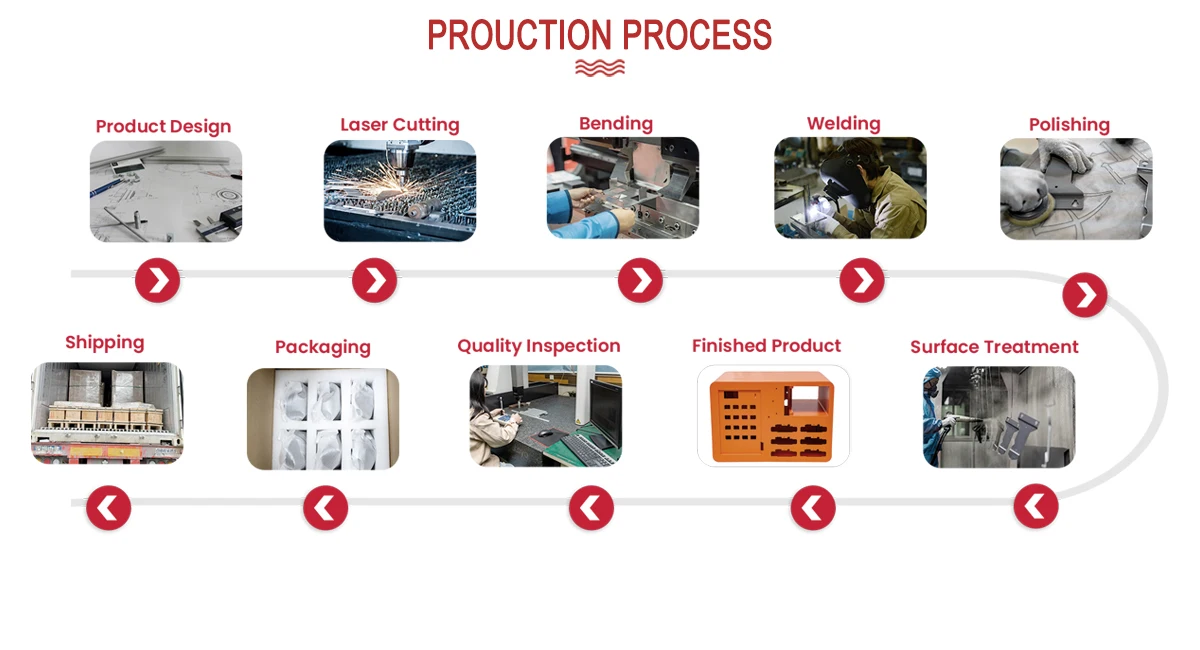

Longwang has 16 years of professional experience in OEM Custom Precision Sheet Metal Fabrication and Sheet Metal Welding Stamping Assembly, as a self-owned factory with IAF and ISO9001 certification, we focus on providing high-precision, one-stop sheet metal component solutions for global B2B customers. Our precision sheet metal fabrication welding assembly service covers the whole process from product design, laser cutting, bending to welding, stamping and final assembly, with a machining tolerance of ±0.0002in, which can meet the ultra-high precision requirements of industrial equipment components. We support customized production according to customer drawings, with a minimum order quantity of 1 PC, and have 7*24H online engineering team to provide drawing review and quotation services, with a quotation response time of only 2 hours. Up to now, we have established long-term cooperative relations with global partners, and the product quality and service have obtained high customer evaluation, making it a reliable supplier of custom stainless steel sheet metal stamping parts and assembly components.

With years of experience in sheet metal fabrication industry, our technical team is proficient in the processing technology of various metal materials, and can realize ODM sheet metal fabrication for industrial equipment with tight tolerance. Self-developed machining process can effectively reduce the cumulative error of multi-process processing and ensure the dimensional accuracy and assembly compatibility of products.

We have a professional online engineering team to provide 7*24H uninterrupted service, complete the review of customer drawings and technical requirements in a short time and give a detailed quotation, which greatly shortens the project preparation cycle. The online communication system supports real-time file transmission and technical communication, realizing seamless connection between customer needs and production design.

By optimizing the production process and adopting lean production management, our production cycle is greatly shortened compared with the industry average, which can quickly meet the customer’s mass production needs. We have a perfect international logistics system, supporting global door-to-door delivery, and can customize the transportation scheme according to the customer’s delivery address and time requirements.

Our OEM Custom Precision Sheet Metal Fabrication service supports a variety of metal materials with detailed models, and can realize the integrated processing of laser cutting, bending, welding, stamping and polishing, avoiding the trouble of multi-supplier cooperation for customers and improving the production efficiency of the whole project.

Item | Specification |

Model | OEM/ODM |

Brand | Longwang |

Main Materials | Aluminum, SPCC, Steel, Stainless Steel, Brass, Titanium Alloy |

Size | Customized based on customer drawings |

Minimum Order Quantity | 1 PC |

Machining Tolerance | ±0.0002in |

Quotation Lead Time | 2 working hours (7*24H online) |

Certification | ISO9001, IAF |

Lead Time Advantage | Shortened production cycle |

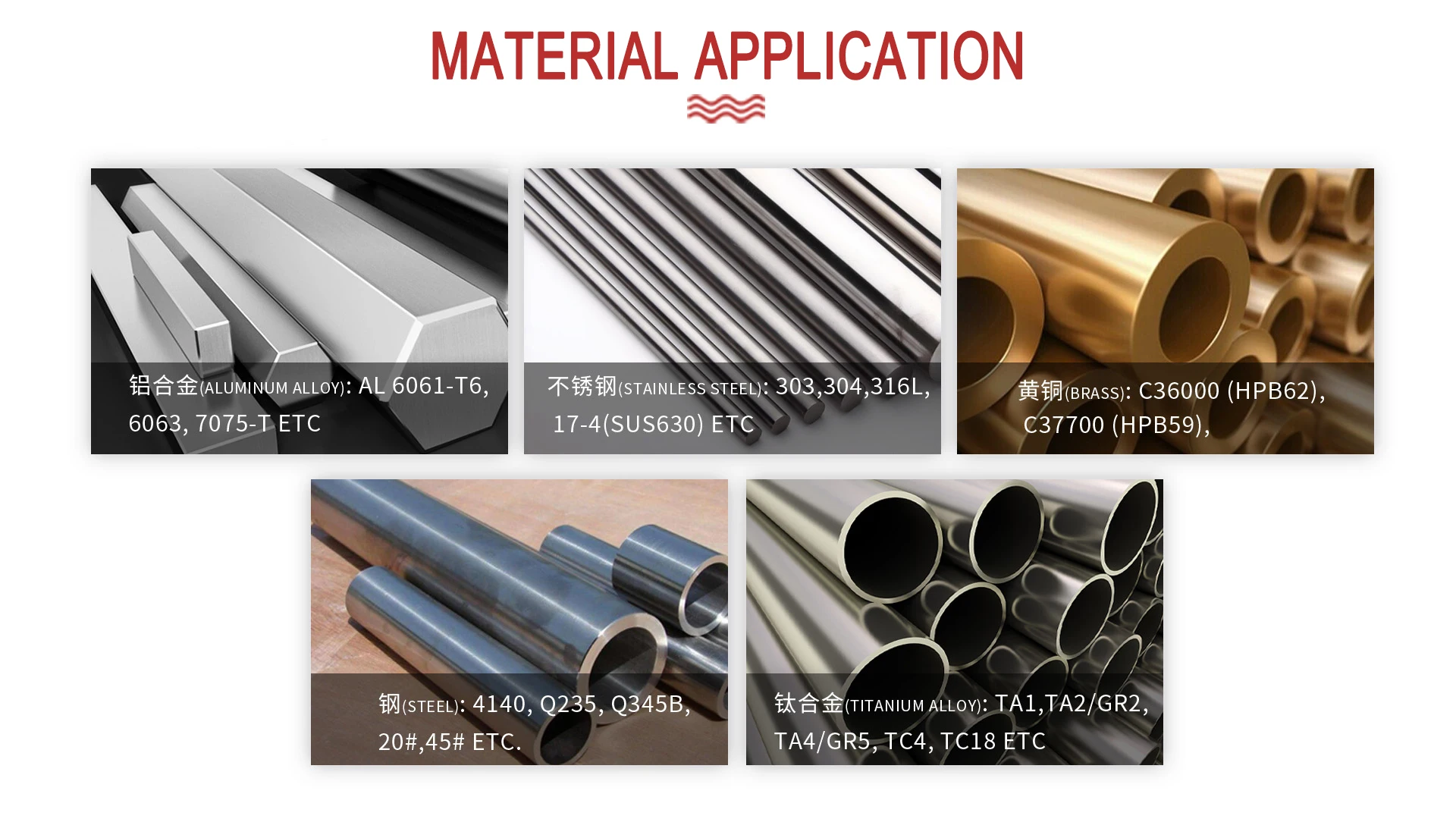

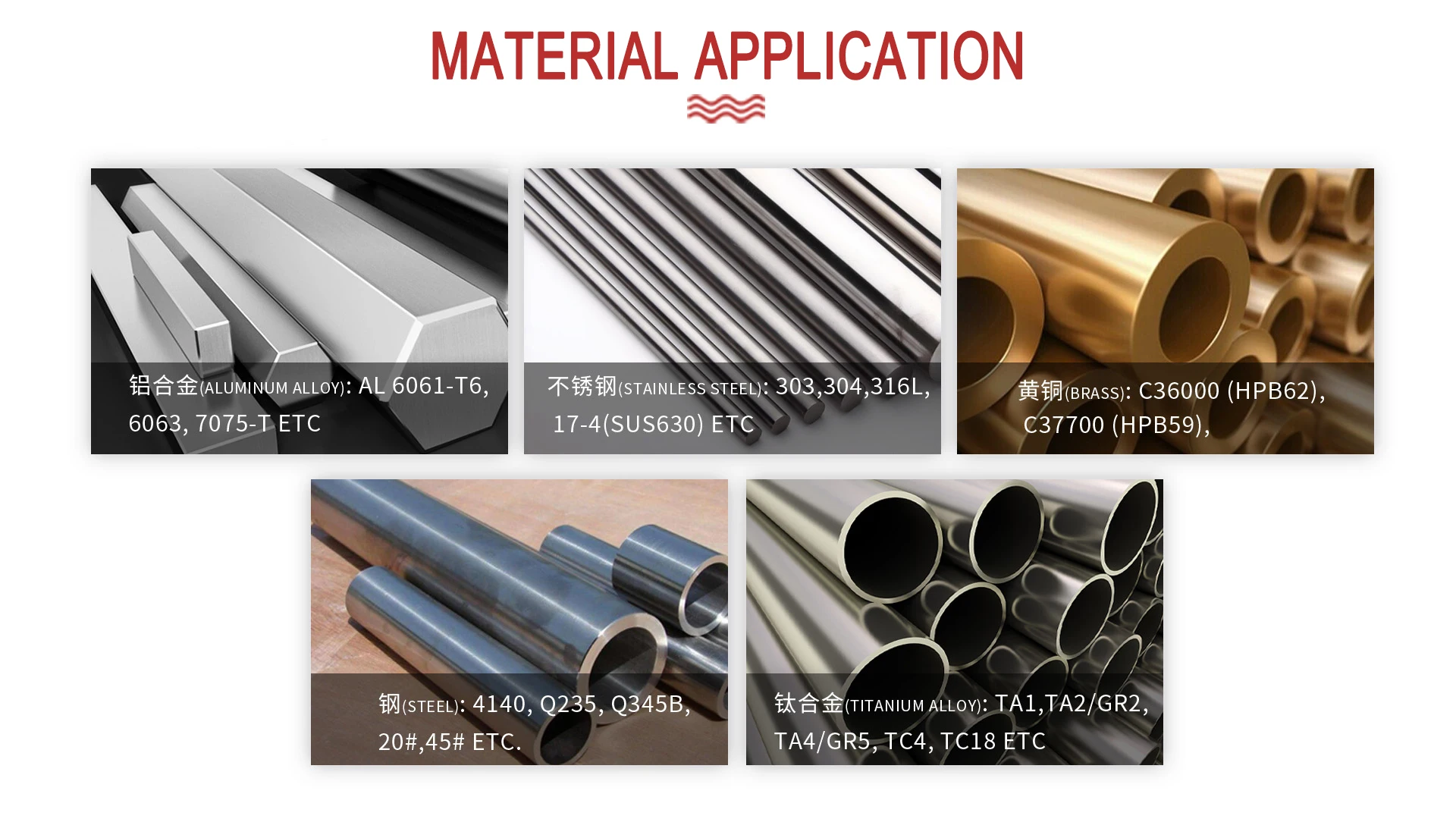

We provide a full range of metal material options for Sheet Metal Welding Stamping Assembly, with detailed models to meet different performance requirements:

Aluminum Alloy: 6061-T6, 6063, 7075-T (light weight, high strength)

Stainless Steel: 303, 304, 316L, 17-4(SUS630) (corrosion resistance, high temperature resistance)

Brass: C36000 (HPB62), C37700 (HPB59) (good electrical conductivity)

Titanium Alloy: TA1, TA2/GR2, TA4/GR5, TC4 (high strength, corrosion resistance)

Steel: 4140, Q235, Q345B, 20#, 45# (high load-bearing capacity)

Drawing Review & Design Optimization: 7*24H engineering team reviews customer drawings, provides professional optimization suggestions and confirms technical parameters.

Laser Cutting: Adopt high-precision laser cutting equipment for blanking, with high cutting accuracy, suitable for complex shape sheet metal parts.

Precision Bending: Use CNC bending machine with angle sensor for bending, and preset rebound compensation to ensure the accuracy of bending angle.

Welding & Stamping: Adopt robot welding and high-precision stamping equipment for integrated processing, with strict control of welding seam and stamping forming quality.

Surface Treatment & Polishing: Carry out pickling, passivation, spraying, plating and other surface treatment, and precision polishing for the parts with high surface finish requirements.

Assembly & Quality Inspection: Assemble the processed parts according to customer requirements, and conduct full dimension detection and assembly performance testing.

Packaging & Shipping: Adopt anti-static, anti-collision customized packaging and arrange international logistics delivery according to the customer’s requirements.

Our OEM Custom Precision Sheet Metal Fabrication and Sheet Metal Welding Stamping Assembly products are widely used in high-end manufacturing industries with strict requirements on precision and assembly:

Industrial Machinery: Precision components of automation equipment, frame assembly of CNC machine tools, hydraulic system sheet metal parts

Automobile & New Energy: New energy vehicle battery shell assembly, automotive electrical system welding parts, chassis stamping components

Medical Equipment: Stainless steel sheet metal parts of medical diagnostic equipment, assembly components of medical instruments

Aerospace & Electronics: Precision titanium alloy sheet metal parts, aerospace equipment welding assembly, high-precision electronic equipment shell

Hardware & Construction: Custom stainless steel hardware assembly, building intelligent equipment sheet metal components, industrial bracket welding parts

We provide one-stop ODM sheet metal fabrication for industrial equipment and OEM customization services, covering the whole process from concept design to finished product delivery.

OEM Service: Strictly follow customer drawings and technical requirements for processing and production, and carry out full-process quality control to ensure that the products are consistent with the drawings.

ODM Service: According to the customer’s project needs and application scenarios, the R&D team provides professional product design, material selection and process optimization solutions, and completes the prototype development and mass production.

Custom Assembly: According to the customer’s assembly requirements, we provide component matching, integrated assembly and performance testing services, and deliver the finished products that can be directly put into use.

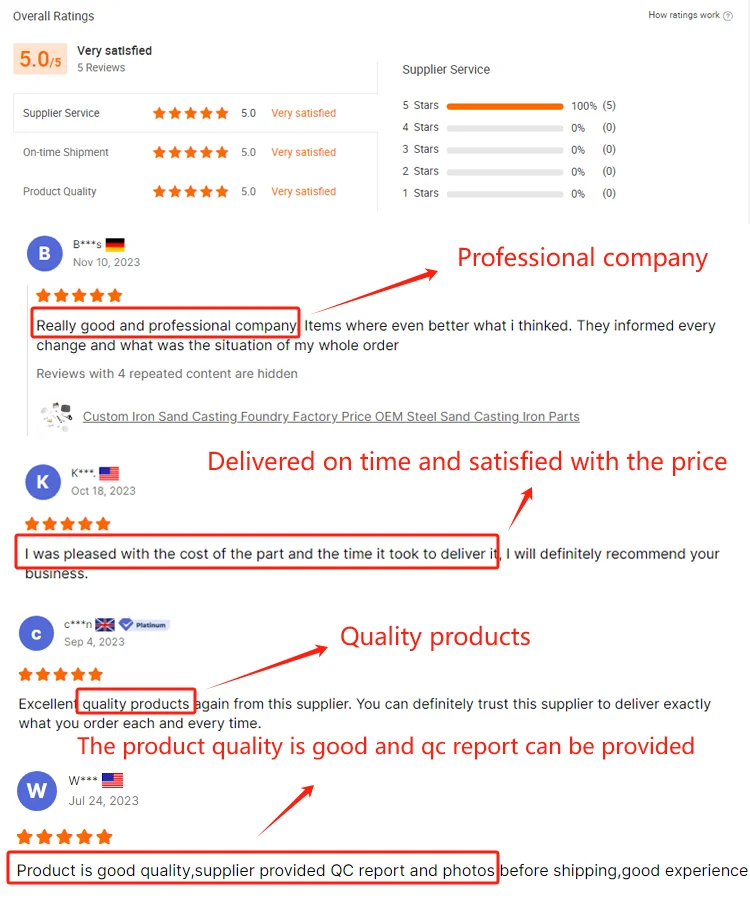

We take quality as the core of development, and build a multi-level quality assurance system with material certification, process control and finished product inspection as the core.

Material Quality Assurance: All raw materials are provided with material certification and quality inspection reports, and the incoming materials are strictly inspected.

Process Real-time Monitoring: Each process is equipped with special inspectors, and the key process parameters are monitored in real time to avoid quality problems caused by process deviation.

Finished Product Comprehensive Inspection: Each batch of products undergoes three-coordinate dimension detection, welding seam inspection and assembly performance testing, and provides detailed QC reports and product photos for customers.

Customer Confirmation Before Shipping: Before delivery, the product samples and inspection reports are sent to customers for confirmation, and the delivery is arranged only after the customer’s approval.

After-sales Quality Tracking: Establish product quality files, track the application effect of products, and provide timely technical support and solution suggestions for customer problems.

We support all mainstream drawing file formats such as CAD, SolidWorks, Pro/E, STEP and IGES. The engineering team can also convert and optimize the file format according to customer needs to ensure the accuracy of drawing recognition.

For small and medium-sized precision sheet metal parts, we can provide free sample production (only charging the mold cost if special molds are needed), and the sample lead time is 3~5 working days, which can meet the customer’s prototype testing needs.

Yes, we provide a full set of quality documents for all products, including material certification, process inspection report, finished product QC report and assembly performance test report, which can meet the customer’s incoming inspection and quality traceability needs.

Longwang has 16 years of professional experience in OEM Custom Precision Sheet Metal Fabrication and Sheet Metal Welding Stamping Assembly, as a self-owned factory with IAF and ISO9001 certification, we focus on providing high-precision, one-stop sheet metal component solutions for global B2B customers. Our precision sheet metal fabrication welding assembly service covers the whole process from product design, laser cutting, bending to welding, stamping and final assembly, with a machining tolerance of ±0.0002in, which can meet the ultra-high precision requirements of industrial equipment components. We support customized production according to customer drawings, with a minimum order quantity of 1 PC, and have 7*24H online engineering team to provide drawing review and quotation services, with a quotation response time of only 2 hours. Up to now, we have established long-term cooperative relations with global partners, and the product quality and service have obtained high customer evaluation, making it a reliable supplier of custom stainless steel sheet metal stamping parts and assembly components.

With years of experience in sheet metal fabrication industry, our technical team is proficient in the processing technology of various metal materials, and can realize ODM sheet metal fabrication for industrial equipment with tight tolerance. Self-developed machining process can effectively reduce the cumulative error of multi-process processing and ensure the dimensional accuracy and assembly compatibility of products.

We have a professional online engineering team to provide 7*24H uninterrupted service, complete the review of customer drawings and technical requirements in a short time and give a detailed quotation, which greatly shortens the project preparation cycle. The online communication system supports real-time file transmission and technical communication, realizing seamless connection between customer needs and production design.

By optimizing the production process and adopting lean production management, our production cycle is greatly shortened compared with the industry average, which can quickly meet the customer’s mass production needs. We have a perfect international logistics system, supporting global door-to-door delivery, and can customize the transportation scheme according to the customer’s delivery address and time requirements.

Our OEM Custom Precision Sheet Metal Fabrication service supports a variety of metal materials with detailed models, and can realize the integrated processing of laser cutting, bending, welding, stamping and polishing, avoiding the trouble of multi-supplier cooperation for customers and improving the production efficiency of the whole project.

Item | Specification |

Model | OEM/ODM |

Brand | Longwang |

Main Materials | Aluminum, SPCC, Steel, Stainless Steel, Brass, Titanium Alloy |

Size | Customized based on customer drawings |

Minimum Order Quantity | 1 PC |

Machining Tolerance | ±0.0002in |

Quotation Lead Time | 2 working hours (7*24H online) |

Certification | ISO9001, IAF |

Lead Time Advantage | Shortened production cycle |

We provide a full range of metal material options for Sheet Metal Welding Stamping Assembly, with detailed models to meet different performance requirements:

Aluminum Alloy: 6061-T6, 6063, 7075-T (light weight, high strength)

Stainless Steel: 303, 304, 316L, 17-4(SUS630) (corrosion resistance, high temperature resistance)

Brass: C36000 (HPB62), C37700 (HPB59) (good electrical conductivity)

Titanium Alloy: TA1, TA2/GR2, TA4/GR5, TC4 (high strength, corrosion resistance)

Steel: 4140, Q235, Q345B, 20#, 45# (high load-bearing capacity)

Drawing Review & Design Optimization: 7*24H engineering team reviews customer drawings, provides professional optimization suggestions and confirms technical parameters.

Laser Cutting: Adopt high-precision laser cutting equipment for blanking, with high cutting accuracy, suitable for complex shape sheet metal parts.

Precision Bending: Use CNC bending machine with angle sensor for bending, and preset rebound compensation to ensure the accuracy of bending angle.

Welding & Stamping: Adopt robot welding and high-precision stamping equipment for integrated processing, with strict control of welding seam and stamping forming quality.

Surface Treatment & Polishing: Carry out pickling, passivation, spraying, plating and other surface treatment, and precision polishing for the parts with high surface finish requirements.

Assembly & Quality Inspection: Assemble the processed parts according to customer requirements, and conduct full dimension detection and assembly performance testing.

Packaging & Shipping: Adopt anti-static, anti-collision customized packaging and arrange international logistics delivery according to the customer’s requirements.

Our OEM Custom Precision Sheet Metal Fabrication and Sheet Metal Welding Stamping Assembly products are widely used in high-end manufacturing industries with strict requirements on precision and assembly:

Industrial Machinery: Precision components of automation equipment, frame assembly of CNC machine tools, hydraulic system sheet metal parts

Automobile & New Energy: New energy vehicle battery shell assembly, automotive electrical system welding parts, chassis stamping components

Medical Equipment: Stainless steel sheet metal parts of medical diagnostic equipment, assembly components of medical instruments

Aerospace & Electronics: Precision titanium alloy sheet metal parts, aerospace equipment welding assembly, high-precision electronic equipment shell

Hardware & Construction: Custom stainless steel hardware assembly, building intelligent equipment sheet metal components, industrial bracket welding parts

We provide one-stop ODM sheet metal fabrication for industrial equipment and OEM customization services, covering the whole process from concept design to finished product delivery.

OEM Service: Strictly follow customer drawings and technical requirements for processing and production, and carry out full-process quality control to ensure that the products are consistent with the drawings.

ODM Service: According to the customer’s project needs and application scenarios, the R&D team provides professional product design, material selection and process optimization solutions, and completes the prototype development and mass production.

Custom Assembly: According to the customer’s assembly requirements, we provide component matching, integrated assembly and performance testing services, and deliver the finished products that can be directly put into use.

We take quality as the core of development, and build a multi-level quality assurance system with material certification, process control and finished product inspection as the core.

Material Quality Assurance: All raw materials are provided with material certification and quality inspection reports, and the incoming materials are strictly inspected.

Process Real-time Monitoring: Each process is equipped with special inspectors, and the key process parameters are monitored in real time to avoid quality problems caused by process deviation.

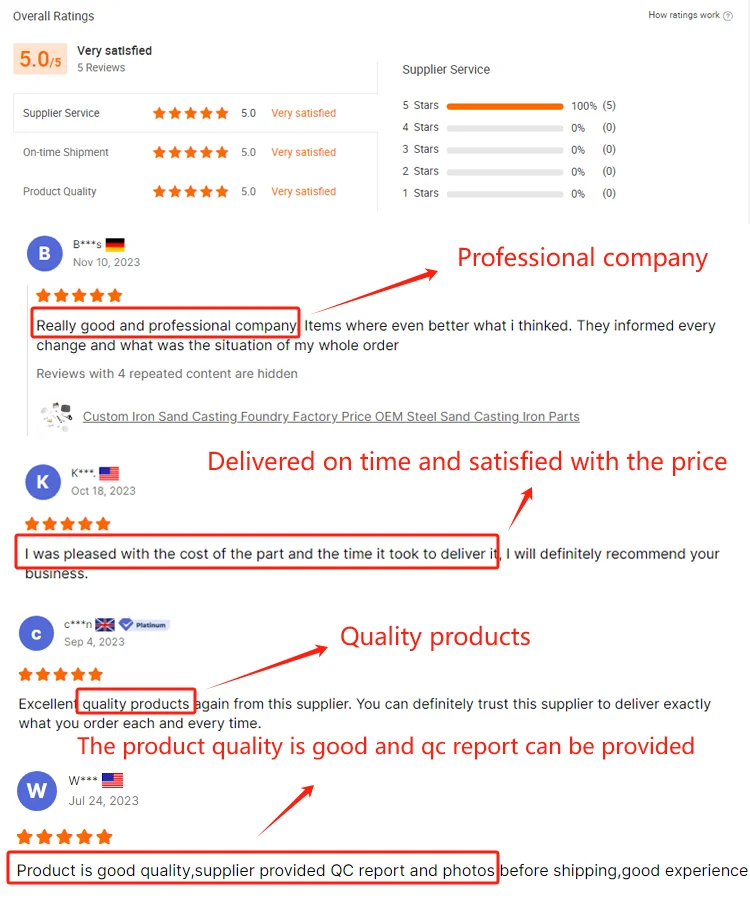

Finished Product Comprehensive Inspection: Each batch of products undergoes three-coordinate dimension detection, welding seam inspection and assembly performance testing, and provides detailed QC reports and product photos for customers.

Customer Confirmation Before Shipping: Before delivery, the product samples and inspection reports are sent to customers for confirmation, and the delivery is arranged only after the customer’s approval.

After-sales Quality Tracking: Establish product quality files, track the application effect of products, and provide timely technical support and solution suggestions for customer problems.

We support all mainstream drawing file formats such as CAD, SolidWorks, Pro/E, STEP and IGES. The engineering team can also convert and optimize the file format according to customer needs to ensure the accuracy of drawing recognition.

For small and medium-sized precision sheet metal parts, we can provide free sample production (only charging the mold cost if special molds are needed), and the sample lead time is 3~5 working days, which can meet the customer’s prototype testing needs.

Yes, we provide a full set of quality documents for all products, including material certification, process inspection report, finished product QC report and assembly performance test report, which can meet the customer’s incoming inspection and quality traceability needs.