Stamping punching parts are integral components in various industries, ranging from automotive to electronics. This manufacturing process involves shaping metal sheets into desired forms using a press machine and a tool and die set. Stamping punching parts are renowned for their precision, cost-effectiveness, and high-volume production capabilities. They play a crucial role in creating intricate designs, shapes, and sizes with consistent quality. From simple brackets to complex components, these parts serve diverse applications, ensuring structural integrity and functionality in the final product.Our expertise lies in creating intricate deep drawing parts and custom stamping punching parts, tailored to meet your exact specifications. With a commitment to excellence and precision, we employ advanced techniques and cutting-edge technology to transform raw materials into high-quality components. Whether you require intricate designs or robust industrial parts, our team of professionals ensures flawless execution, delivering products that exceed expectations. Explore the realm of custom fabrication with us, where innovation meets perfection

| Material: | |

|---|---|

| Size: | |

| Availability: | |

| Quantity: | |

OEM/ODM

Sheet metal fabrication is the core of industrial component manufacturing, and our custom deep drawing sheet metal parts and professional custom stamping parts are engineered to meet the strictest structural and functional requirements of ToB industrial clients. With 16 years of OEM/ODM experience in metal forming, Longwang Hardware specializes in producing precision stamping punching parts from simple brackets to complex deep-drawn components, featuring high consistency, structural integrity and cost-effectiveness for mass production. Our deep drawing parts are manufactured via advanced press machine and die set technology, ensuring intricate geometries and tight dimensional control that exceed industry standards. As a self-owned factory, we integrate the entire production chain from raw material selection to finished product delivery, making us a reliable one-stop supplier for global industrial clients in need of customized sheet metal solutions.

24 professional engineers are on standby to review your custom drawings and provide detailed quotations within 2 hours, eliminating communication delays for urgent industrial projects.

Our custom stamping parts achieve a tolerance of ±0.0002in, 10× higher precision than mainstream suppliers, meeting the micro-dimensional requirements of high-precision industrial equipment.

With instant online quoting and efficient production scheduling, we cut the entire production cycle by up to 50%, ensuring on-time delivery for your mass production and project progress.

We integrate design optimization, material procurement, processing, surface treatment and quality inspection, saving clients the hassle of multi-supplier coordination and reducing procurement costs.

Item | Specification |

Main Material | Aluminum, SPCC, Carbon Steel, Stainless Steel |

Size | Fully customized based on client’s 2D/3D drawing |

MOQ | 1 PCS (support small batch trial production) |

Tolerance | ±0.0002in (10× tighter than industry average) |

Model | OEM/ODM (custom design supported) |

Surface Treatment | Polishing, electroplating, painting (customized) |

Delivery Term | Negotiable (air/sea shipping for global clients) |

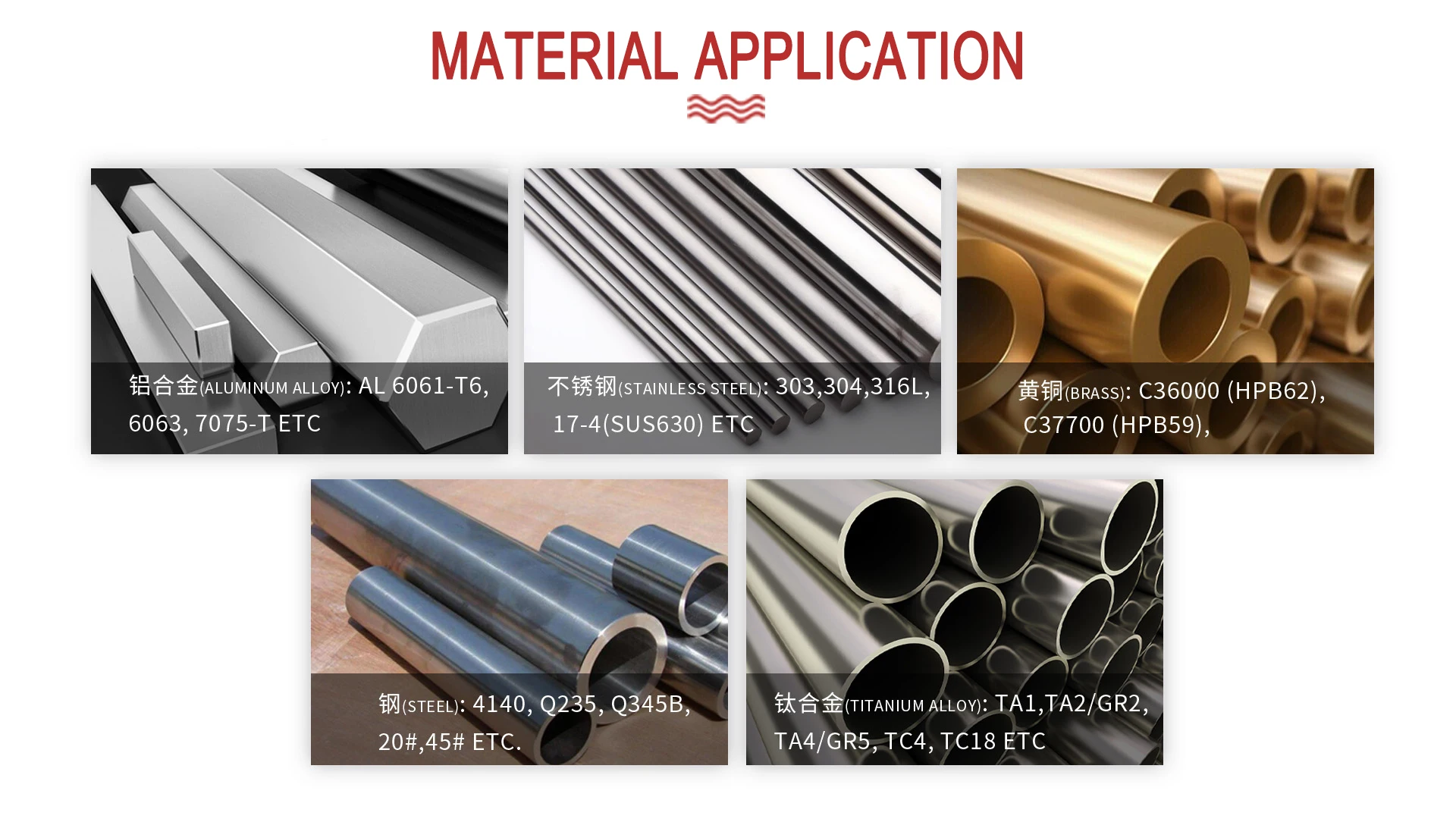

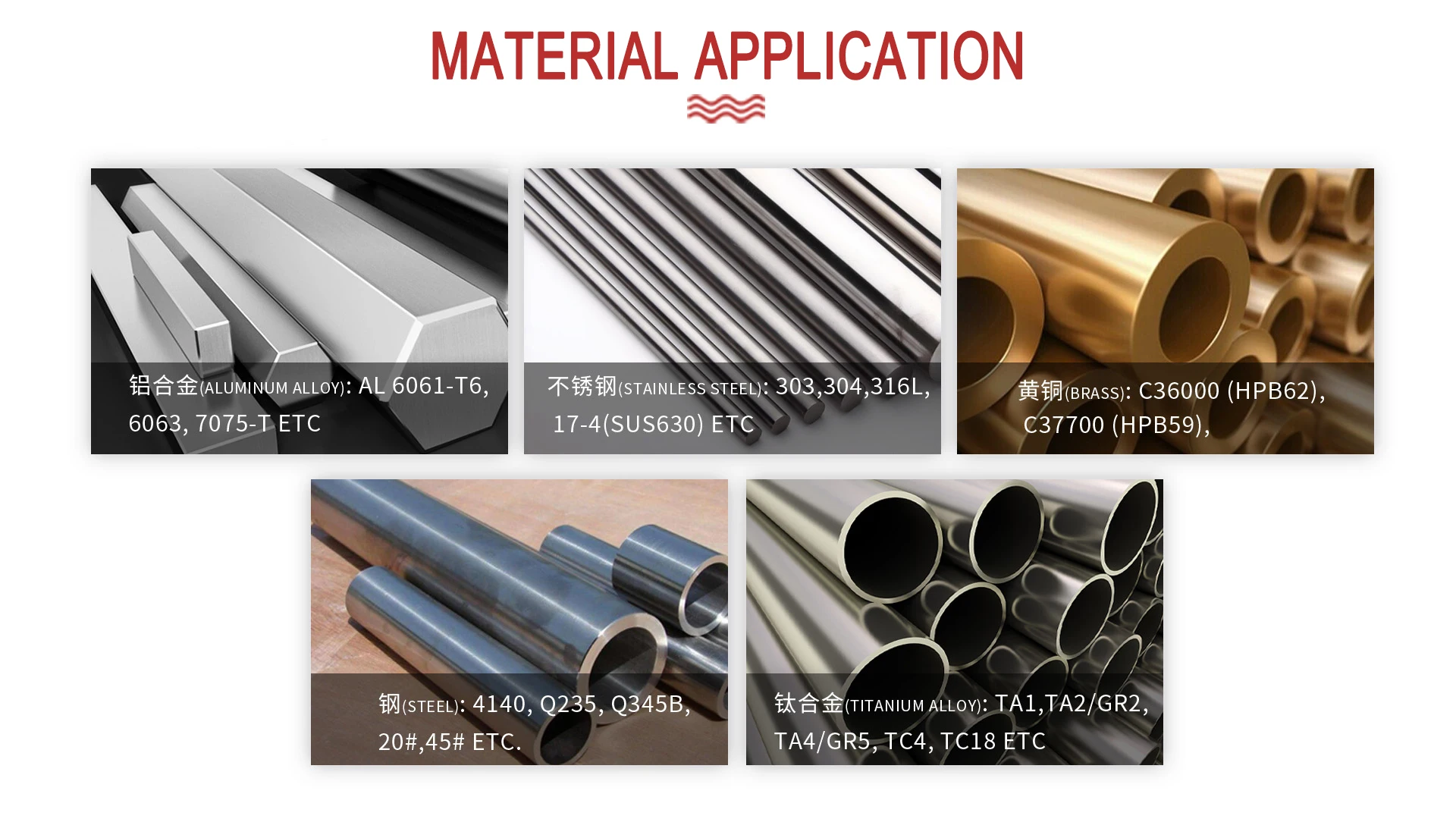

We offer a full range of industrial-grade materials to match different application scenarios:

Aluminum Alloy: 6061-T6, 6063, 7075-T (lightweight, high strength for automotive/electronics)

Steel: 4140, Q235, Q345B, 20#, 45# (robust for heavy industrial components)

Stainless Steel: 303, 304, 316L (corrosion-resistant for harsh environments)

Brass/Titanium Alloy: C36000, TA1, TC4 (special material for precision equipment)

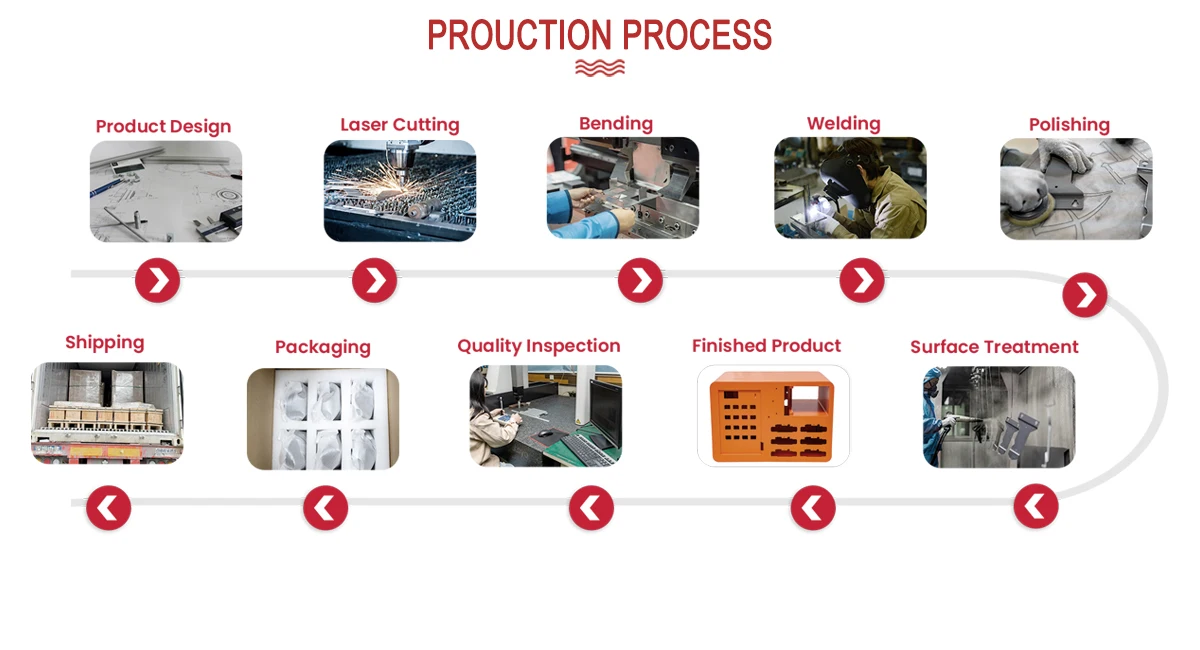

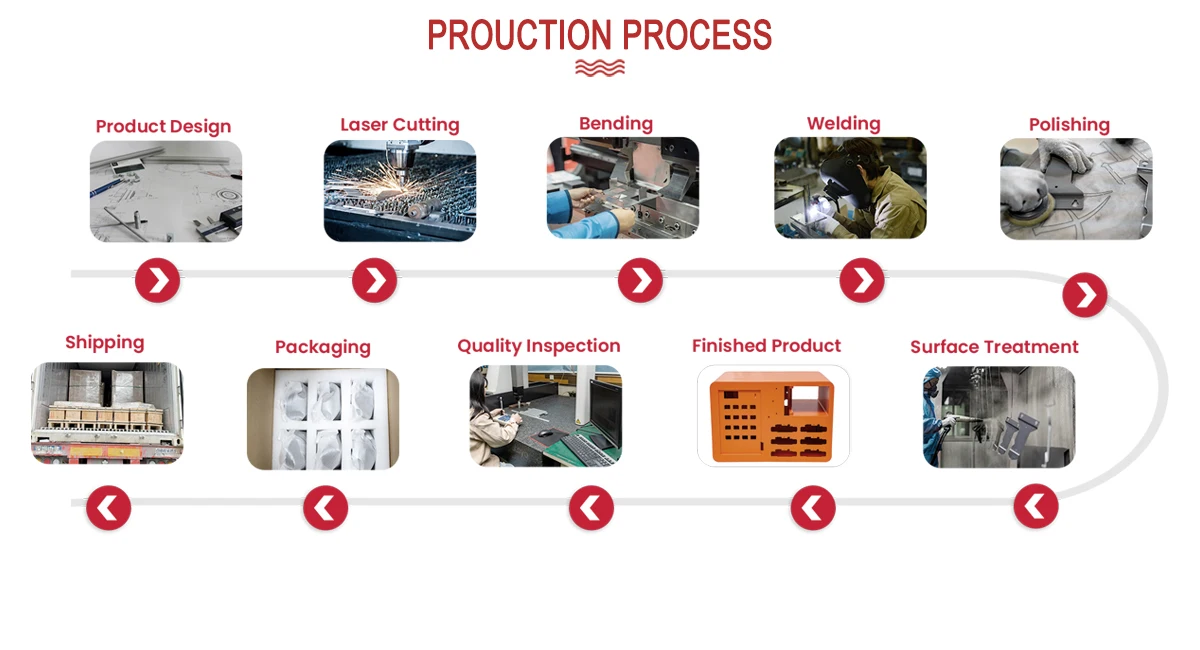

Our sheet metal fabrication process follows strict industrial standards: Product Design & Optimization → Laser Cutting → Bending → Welding → Polishing → Surface Treatment → Multi-step Quality Inspection → Packaging → Global Shipping. Each step is supervised by professional technicians to ensure the consistency of deep drawing parts and custom stamping parts.

Our custom deep drawing sheet metal parts and precision stamping punching parts are widely used in key industrial sectors:

Automotive Industry: Chassis brackets, engine components, body structural parts

Electronics Industry: Precision instrument housings, connector stamping parts, circuit board fixtures

General Industrial Equipment: Hydraulic machine components, conveyor system parts, hardware fasteners

Household Appliance Industry: Air conditioning/Refrigerator structural parts, kitchen equipment components

All products adapt to the high-load and long-term operation requirements of industrial equipment, with stable performance and long service life.

We provide end-to-end custom sheet metal fabrication OEM/ODM service tailored to client needs:

Accept all 2D/3D drawing formats (CAD, SolidWorks, etc.) and offer free design optimization suggestions for processability and cost reduction;

Support small-batch trial production (MOQ 1 PCS) for prototype verification, and flexible mass production adjustment;

Customize material selection, surface treatment and packaging according to the client’s application environment and shipping requirements;

Real-time production progress feedback, keeping clients informed of every production link.

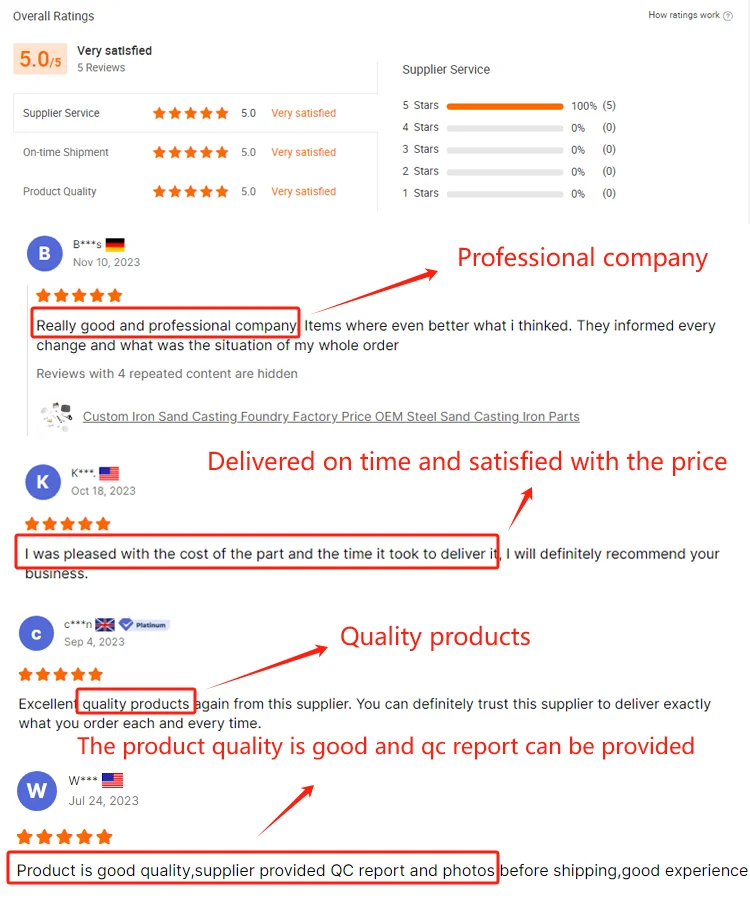

Certification & Inspection: We have complete quality management system, providing material certification, conformity certificate and advanced inspection reports for all products;

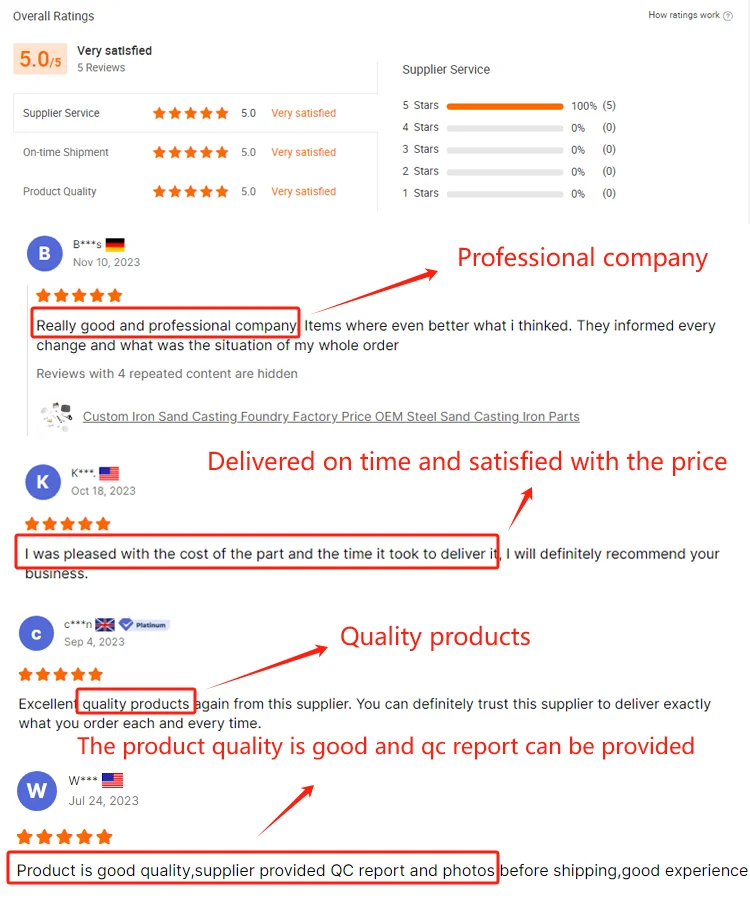

Global Cooperation: 16 years of industry experience, maintaining long-term cooperative relations with more than 5000 global partners, with a 5.0/5 overall rating on product quality and service;

Pre-Shipment Inspection: 100% full inspection before delivery, providing QC report and product photos to ensure zero defective products shipped out;

After-Sales Service: Professional after-sales team to solve product usage problems in a timely manner, with a perfect problem feedback and solution mechanism.

Our MOQ is only 1 PCS, which supports small-batch trial production for your prototype testing, and we offer favorable prices for mass production orders.

Yes, our professional engineering team will provide free design optimization suggestions according to the processing technology and material characteristics, to improve product processability and reduce production costs.

The delivery time is determined by the order quantity and product complexity, and we can shorten the production cycle by up to 50% compared with the industry average to ensure on-time delivery.

Sheet metal fabrication is the core of industrial component manufacturing, and our custom deep drawing sheet metal parts and professional custom stamping parts are engineered to meet the strictest structural and functional requirements of ToB industrial clients. With 16 years of OEM/ODM experience in metal forming, Longwang Hardware specializes in producing precision stamping punching parts from simple brackets to complex deep-drawn components, featuring high consistency, structural integrity and cost-effectiveness for mass production. Our deep drawing parts are manufactured via advanced press machine and die set technology, ensuring intricate geometries and tight dimensional control that exceed industry standards. As a self-owned factory, we integrate the entire production chain from raw material selection to finished product delivery, making us a reliable one-stop supplier for global industrial clients in need of customized sheet metal solutions.

24 professional engineers are on standby to review your custom drawings and provide detailed quotations within 2 hours, eliminating communication delays for urgent industrial projects.

Our custom stamping parts achieve a tolerance of ±0.0002in, 10× higher precision than mainstream suppliers, meeting the micro-dimensional requirements of high-precision industrial equipment.

With instant online quoting and efficient production scheduling, we cut the entire production cycle by up to 50%, ensuring on-time delivery for your mass production and project progress.

We integrate design optimization, material procurement, processing, surface treatment and quality inspection, saving clients the hassle of multi-supplier coordination and reducing procurement costs.

Item | Specification |

Main Material | Aluminum, SPCC, Carbon Steel, Stainless Steel |

Size | Fully customized based on client’s 2D/3D drawing |

MOQ | 1 PCS (support small batch trial production) |

Tolerance | ±0.0002in (10× tighter than industry average) |

Model | OEM/ODM (custom design supported) |

Surface Treatment | Polishing, electroplating, painting (customized) |

Delivery Term | Negotiable (air/sea shipping for global clients) |

We offer a full range of industrial-grade materials to match different application scenarios:

Aluminum Alloy: 6061-T6, 6063, 7075-T (lightweight, high strength for automotive/electronics)

Steel: 4140, Q235, Q345B, 20#, 45# (robust for heavy industrial components)

Stainless Steel: 303, 304, 316L (corrosion-resistant for harsh environments)

Brass/Titanium Alloy: C36000, TA1, TC4 (special material for precision equipment)

Our sheet metal fabrication process follows strict industrial standards: Product Design & Optimization → Laser Cutting → Bending → Welding → Polishing → Surface Treatment → Multi-step Quality Inspection → Packaging → Global Shipping. Each step is supervised by professional technicians to ensure the consistency of deep drawing parts and custom stamping parts.

Our custom deep drawing sheet metal parts and precision stamping punching parts are widely used in key industrial sectors:

Automotive Industry: Chassis brackets, engine components, body structural parts

Electronics Industry: Precision instrument housings, connector stamping parts, circuit board fixtures

General Industrial Equipment: Hydraulic machine components, conveyor system parts, hardware fasteners

Household Appliance Industry: Air conditioning/Refrigerator structural parts, kitchen equipment components

All products adapt to the high-load and long-term operation requirements of industrial equipment, with stable performance and long service life.

We provide end-to-end custom sheet metal fabrication OEM/ODM service tailored to client needs:

Accept all 2D/3D drawing formats (CAD, SolidWorks, etc.) and offer free design optimization suggestions for processability and cost reduction;

Support small-batch trial production (MOQ 1 PCS) for prototype verification, and flexible mass production adjustment;

Customize material selection, surface treatment and packaging according to the client’s application environment and shipping requirements;

Real-time production progress feedback, keeping clients informed of every production link.

Certification & Inspection: We have complete quality management system, providing material certification, conformity certificate and advanced inspection reports for all products;

Global Cooperation: 16 years of industry experience, maintaining long-term cooperative relations with more than 5000 global partners, with a 5.0/5 overall rating on product quality and service;

Pre-Shipment Inspection: 100% full inspection before delivery, providing QC report and product photos to ensure zero defective products shipped out;

After-Sales Service: Professional after-sales team to solve product usage problems in a timely manner, with a perfect problem feedback and solution mechanism.

Our MOQ is only 1 PCS, which supports small-batch trial production for your prototype testing, and we offer favorable prices for mass production orders.

Yes, our professional engineering team will provide free design optimization suggestions according to the processing technology and material characteristics, to improve product processability and reduce production costs.

The delivery time is determined by the order quantity and product complexity, and we can shorten the production cycle by up to 50% compared with the industry average to ensure on-time delivery.