We have a professional team and advanced stamping technology to provide you with a full range of customized solutions to meet your needs for high-quality parts and components, allowing your project to be optimized in terms of quality and efficiency.

| Availability: | |

|---|---|

| Quantity: | |

|

| |

OEM/ODM

Longwang

Longwang is a leading manufacturer offering Custom Machining Metal Bracket and professional Sheet Metal Stamping Services for global B2B clients, with ISO9001/IATF16949 certified production lines and a professional R&D and manufacturing team. We focus on providing one-stop customized stamping solutions for high-quality metal bracket components, realizing project optimization in quality and production efficiency through advanced stamping technology and precision mold design. Our precision sheet metal stamping for industrial brackets supports small and large batch production with a minimum order quantity of 1 PC, and the sample response cycle is only 3~7 working days, which can quickly meet the prototype testing and mass production needs of customers in different industries. Our stamping services cover a variety of metal materials, and the close tolerance processing ensures the dimensional accuracy of each custom steel aluminum bracket stamping part, making it the first choice for industrial bracket component procurement.

We invest in the world’s top stamping equipment and build an automated production line, which not only improves the production efficiency of Sheet Metal Stamping Services but also ensures the consistency of product precision. The high-precision stamping mold design can realize the integrated forming of complex metal bracket structures, reducing the subsequent assembly process and saving customer production costs.

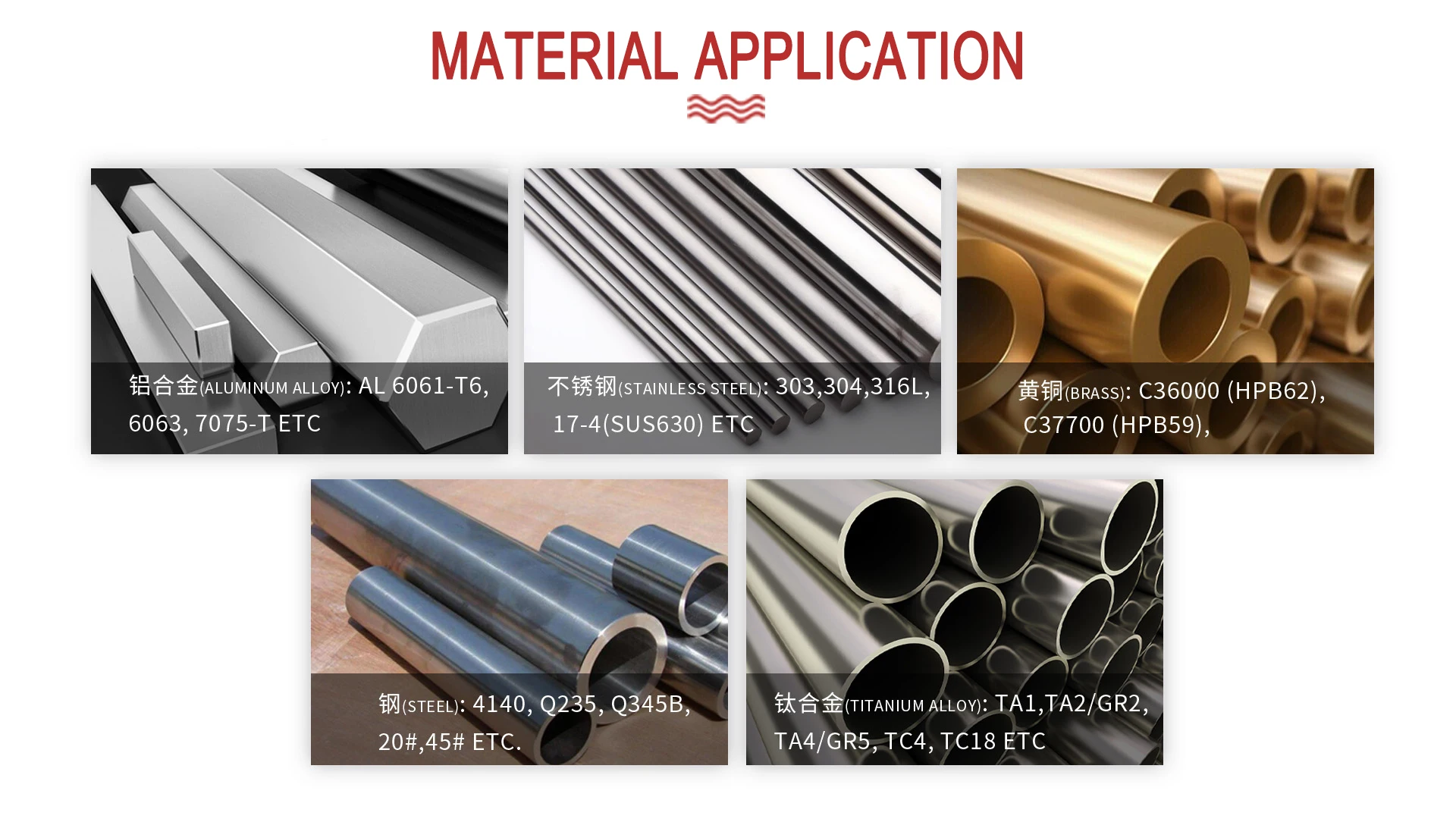

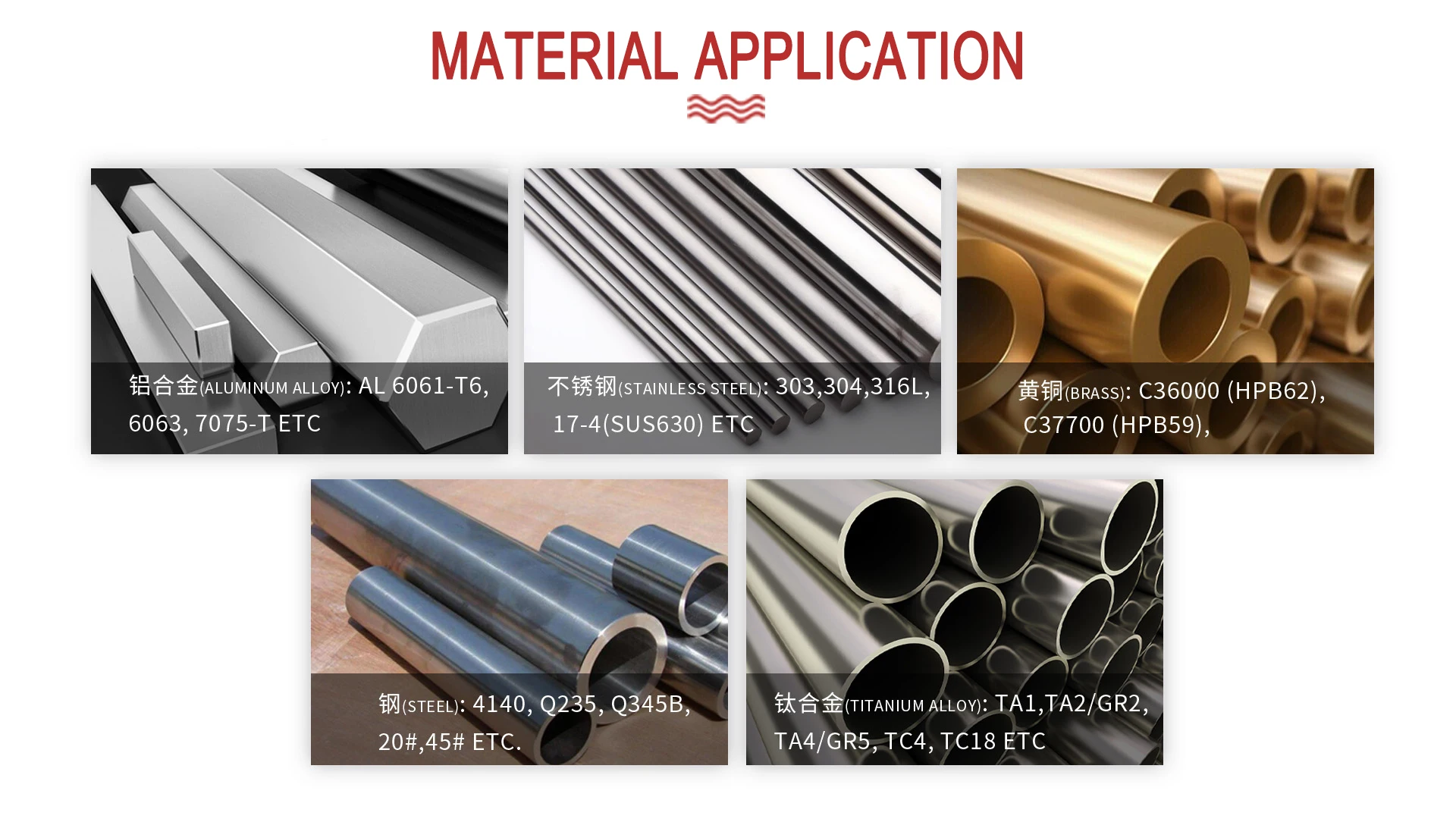

Our Custom Machining Metal Bracket service supports steel, aluminum alloy and other customized metal materials, and can flexibly adjust the material selection scheme according to the mechanical performance requirements of different industry brackets. The material procurement system has long-term cooperation with well-known raw material suppliers to ensure the stability of material quality.

With a dedicated engineering team responsible for sample development, we can complete the design and production of OEM metal bracket stamping solutions within 3~7 working days, helping customers speed up the product iteration cycle. We provide one-stop services including design improvement, stamping production, component assembly and transportation cost consultation, realizing the whole process of project follow-up from design to delivery.

Item | Specification |

Model | OEM/ODM |

Brand | Longwang |

Unit Price | Negotiable |

Minimum Order Quantity | 1 PC |

Sample Lead Time | 3~7 working days |

Certification | ISO9001, IATF16949 |

Tolerance | Close tolerance (customizable by demand) |

Surface Treatment | Customized (electrophoresis, spraying, plating etc.) |

The main materials for Custom Machining Metal Bracket include cold-rolled steel, hot-rolled steel, 6061/6063 aluminum alloy and other metal materials, all of which pass the material certification and provide quality inspection reports to ensure compliance with industry standards.

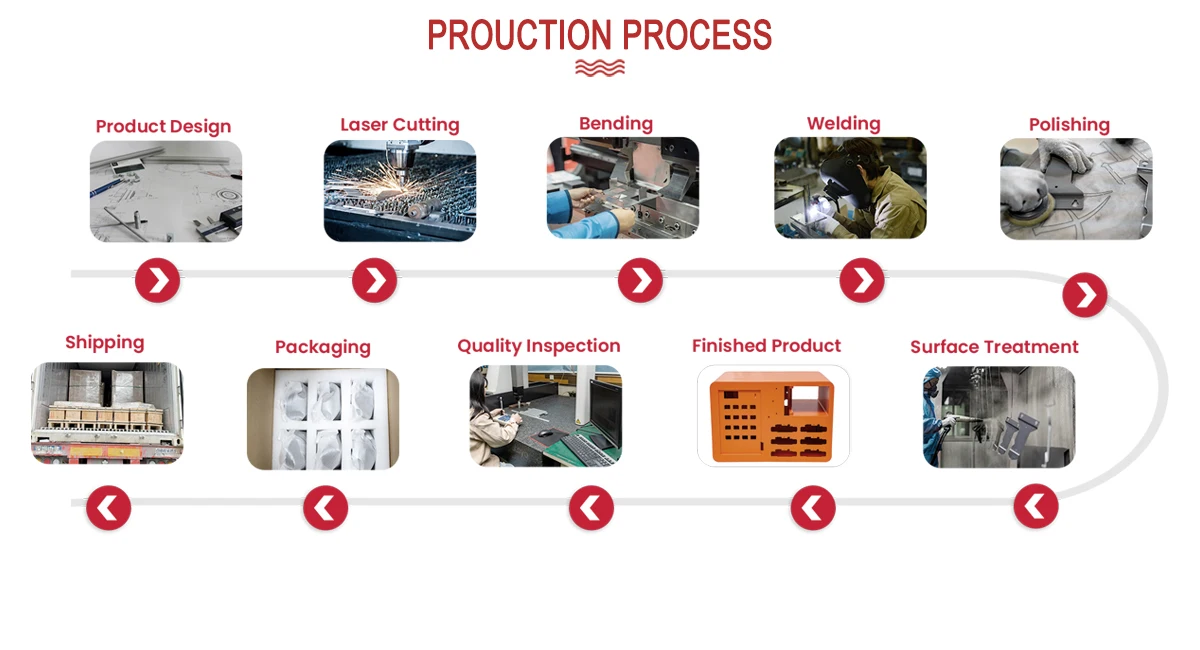

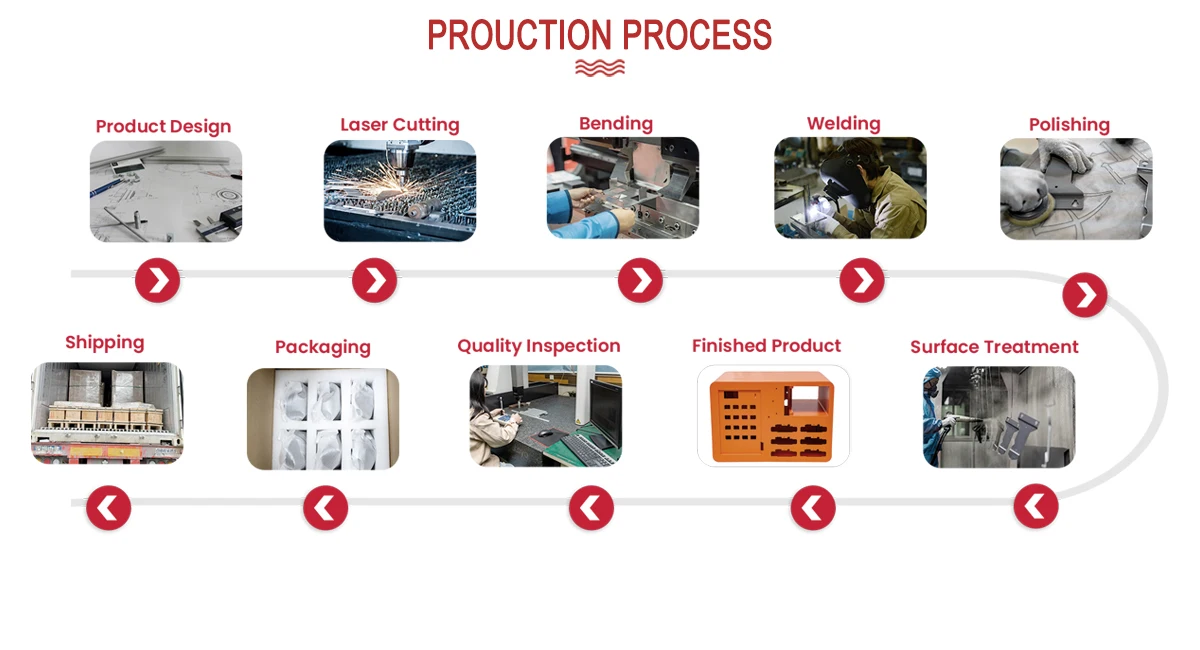

Mold Design & Development: According to customer drawings and technical requirements, design precision stamping molds and conduct simulation testing to ensure forming accuracy.

Precision Stamping: Adopt automated stamping equipment for integrated forming, with real-time monitoring of the production process to avoid dimensional errors.

Post-processing: Carry out edge trimming, deburring and surface treatment according to customer needs to improve the surface quality and corrosion resistance of brackets.

Quality Testing: Conduct full dimension inspection and mechanical performance testing on the stamped brackets to ensure that they meet the customer’s technical requirements.

Assembly & Packaging: Provide customized assembly services for bracket components and adopt anti-collision packaging to ensure the safety of transportation.

Our Sheet Metal Stamping Services and Custom Machining Metal Bracket products are widely used in core manufacturing industries with high precision requirements:

Automobile Manufacturing: Chassis brackets, engine compartment accessories, electrical system fixing brackets

Electronic Equipment: Server rack brackets, industrial control equipment shell brackets, communication equipment fixing parts

Aerospace: Lightweight aluminum alloy brackets for aerospace precision components

Home Appliances: Inner and outer brackets of air conditioners, refrigerators and washing machines

Machinery Manufacturing & Construction: Construction machinery load-bearing brackets, industrial equipment frame components, building hardware fixing brackets

We focus on customer-oriented OEM metal bracket stamping solutions, and the engineering team will communicate with customers in depth to understand the product application scenarios, mechanical performance and installation requirements. For ODM projects, we can provide professional design optimization suggestions according to the customer’s project needs, such as mold structure improvement, material selection optimization and process simplification, to balance product precision and production cost. The whole customization process is transparent, and the production progress is fed back to customers in real time to ensure that the final products meet the expected requirements.

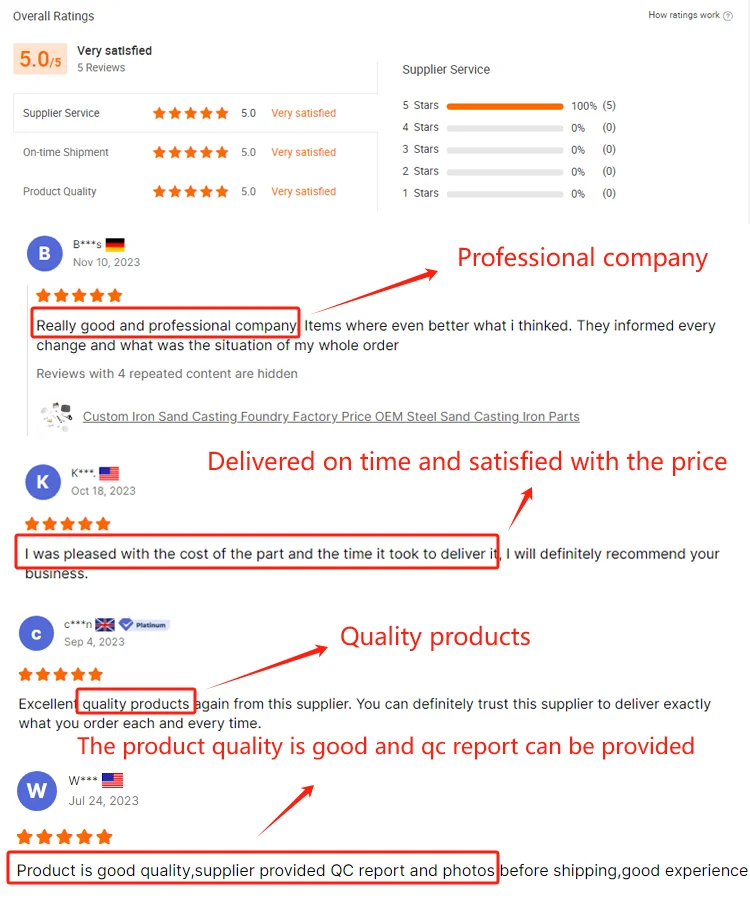

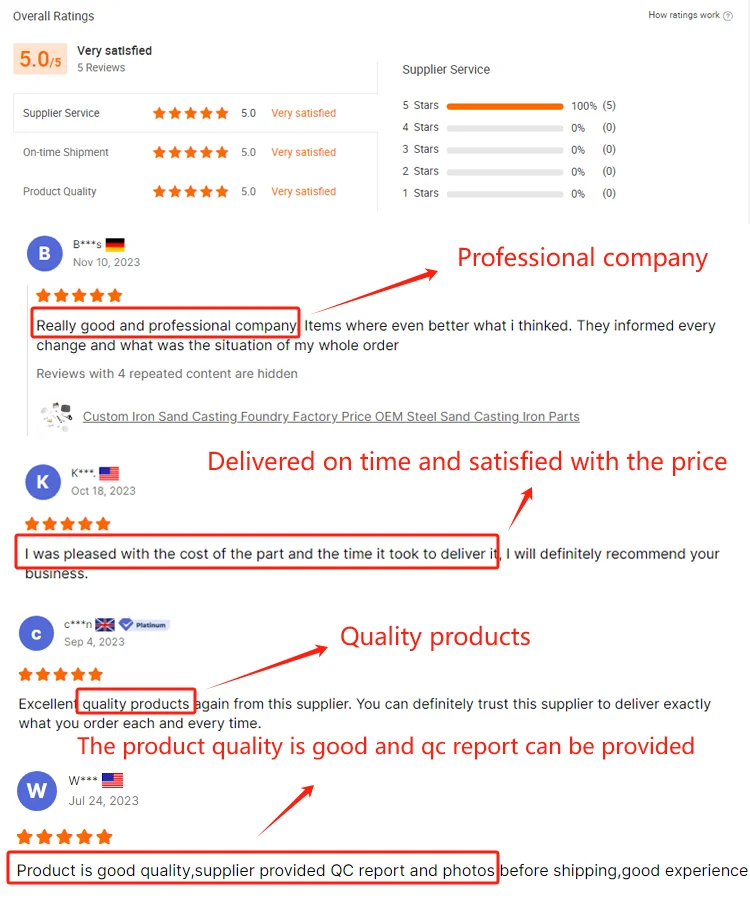

We have established a strict whole-process quality management system, which runs through from raw material procurement to finished product delivery.

Raw material inspection: All incoming materials are inspected for physical and chemical properties, and unqualified materials are rejected.

Process inspection: Conduct random inspection on the semi-finished products in the stamping process to ensure the stability of process parameters.

Finished product inspection: Each batch of brackets undergoes comprehensive dimension detection and performance testing, and the inspection report is provided for customer confirmation.

After-sales tracking: Establish product quality files and track the application effect of products in customer production to provide timely technical support.

The mass production lead time is determined according to the order quantity and product complexity, generally 7~15 working days for small and medium batches, and we will customize the production plan for large batches to ensure on-time delivery.

Yes, our engineering team will provide detailed mold design drawings and simulation test reports for customers to confirm before mold production, and modify them according to customer’s suggestions to ensure the rationality of mold design.

We promise a 100% quality guarantee for all products. If there are quality problems caused by our production process, we will rework or replace the products unconditionally, and send professional technicians to communicate and solve the problems in time.

Longwang is a leading manufacturer offering Custom Machining Metal Bracket and professional Sheet Metal Stamping Services for global B2B clients, with ISO9001/IATF16949 certified production lines and a professional R&D and manufacturing team. We focus on providing one-stop customized stamping solutions for high-quality metal bracket components, realizing project optimization in quality and production efficiency through advanced stamping technology and precision mold design. Our precision sheet metal stamping for industrial brackets supports small and large batch production with a minimum order quantity of 1 PC, and the sample response cycle is only 3~7 working days, which can quickly meet the prototype testing and mass production needs of customers in different industries. Our stamping services cover a variety of metal materials, and the close tolerance processing ensures the dimensional accuracy of each custom steel aluminum bracket stamping part, making it the first choice for industrial bracket component procurement.

We invest in the world’s top stamping equipment and build an automated production line, which not only improves the production efficiency of Sheet Metal Stamping Services but also ensures the consistency of product precision. The high-precision stamping mold design can realize the integrated forming of complex metal bracket structures, reducing the subsequent assembly process and saving customer production costs.

Our Custom Machining Metal Bracket service supports steel, aluminum alloy and other customized metal materials, and can flexibly adjust the material selection scheme according to the mechanical performance requirements of different industry brackets. The material procurement system has long-term cooperation with well-known raw material suppliers to ensure the stability of material quality.

With a dedicated engineering team responsible for sample development, we can complete the design and production of OEM metal bracket stamping solutions within 3~7 working days, helping customers speed up the product iteration cycle. We provide one-stop services including design improvement, stamping production, component assembly and transportation cost consultation, realizing the whole process of project follow-up from design to delivery.

Item | Specification |

Model | OEM/ODM |

Brand | Longwang |

Unit Price | Negotiable |

Minimum Order Quantity | 1 PC |

Sample Lead Time | 3~7 working days |

Certification | ISO9001, IATF16949 |

Tolerance | Close tolerance (customizable by demand) |

Surface Treatment | Customized (electrophoresis, spraying, plating etc.) |

The main materials for Custom Machining Metal Bracket include cold-rolled steel, hot-rolled steel, 6061/6063 aluminum alloy and other metal materials, all of which pass the material certification and provide quality inspection reports to ensure compliance with industry standards.

Mold Design & Development: According to customer drawings and technical requirements, design precision stamping molds and conduct simulation testing to ensure forming accuracy.

Precision Stamping: Adopt automated stamping equipment for integrated forming, with real-time monitoring of the production process to avoid dimensional errors.

Post-processing: Carry out edge trimming, deburring and surface treatment according to customer needs to improve the surface quality and corrosion resistance of brackets.

Quality Testing: Conduct full dimension inspection and mechanical performance testing on the stamped brackets to ensure that they meet the customer’s technical requirements.

Assembly & Packaging: Provide customized assembly services for bracket components and adopt anti-collision packaging to ensure the safety of transportation.

Our Sheet Metal Stamping Services and Custom Machining Metal Bracket products are widely used in core manufacturing industries with high precision requirements:

Automobile Manufacturing: Chassis brackets, engine compartment accessories, electrical system fixing brackets

Electronic Equipment: Server rack brackets, industrial control equipment shell brackets, communication equipment fixing parts

Aerospace: Lightweight aluminum alloy brackets for aerospace precision components

Home Appliances: Inner and outer brackets of air conditioners, refrigerators and washing machines

Machinery Manufacturing & Construction: Construction machinery load-bearing brackets, industrial equipment frame components, building hardware fixing brackets

We focus on customer-oriented OEM metal bracket stamping solutions, and the engineering team will communicate with customers in depth to understand the product application scenarios, mechanical performance and installation requirements. For ODM projects, we can provide professional design optimization suggestions according to the customer’s project needs, such as mold structure improvement, material selection optimization and process simplification, to balance product precision and production cost. The whole customization process is transparent, and the production progress is fed back to customers in real time to ensure that the final products meet the expected requirements.

We have established a strict whole-process quality management system, which runs through from raw material procurement to finished product delivery.

Raw material inspection: All incoming materials are inspected for physical and chemical properties, and unqualified materials are rejected.

Process inspection: Conduct random inspection on the semi-finished products in the stamping process to ensure the stability of process parameters.

Finished product inspection: Each batch of brackets undergoes comprehensive dimension detection and performance testing, and the inspection report is provided for customer confirmation.

After-sales tracking: Establish product quality files and track the application effect of products in customer production to provide timely technical support.

The mass production lead time is determined according to the order quantity and product complexity, generally 7~15 working days for small and medium batches, and we will customize the production plan for large batches to ensure on-time delivery.

Yes, our engineering team will provide detailed mold design drawings and simulation test reports for customers to confirm before mold production, and modify them according to customer’s suggestions to ensure the rationality of mold design.

We promise a 100% quality guarantee for all products. If there are quality problems caused by our production process, we will rework or replace the products unconditionally, and send professional technicians to communicate and solve the problems in time.